A full day

Beginner

$51–100

Introduction

Tough, inexpensive DIY workbenches made from pine will do good service for generations. Using this simple plan you can build one in a morning.

Tools Required

- Caulk gun

- Circular saw

- Cordless drill

- Drill bit set

- Framing square

- Level

- Miter saw

- Orbital sander

- Safety glasses

- Tape measure

If this workbench looks familiar, it’s probably because you’ve seen one a lot like it in your father’s or grandfather’s shop. Variations of this simple workbench design have been around for decades, and for good reason: The bench is strong, practical and super easy to build. You can run to the lumberyard in the morning, grab a few boards, and by noon you’ll have a perfectly functional workbench.

The workbench isn’t fancy—it’s built from standard construction lumber. But you can easily customize it with drawers and other easy DIY workbench upgrades.

Cut the parts according to the cutting list. We used a miter saw, but a circular saw will work fine. Mark the 2x4s with a speed square or combination square. Then carefully cut the boards to length. If you plan to stain or paint the bench, now is the time to sand the parts. And to really simplify your job, you could also stain or paint the parts before you assemble the bench.

The overall dimensions of the DIY workbench are: 60′ wide x 28-1/4′ deep x 36′ tall plus a 7-3/4′ backboard. But you can easily adapt the plan to fit your space.

Project step-by-step (6)

Build the Top and Shelf Frames

- Use 3-in. screws to assemble the frames that support the top and the shelf. To avoid splitting the 2x4s, either drill pilot holes or use self-drilling screws. Build both frames and set the top frame aside.

- Note: We used an old door propped up on sawhorses as a work surface, but the floor will work too.

- Lay the 2x4s for the front and back of the top and shelf on the work surface and mark the centers.

- Pro tip: Remember, if you’re not using self-drilling screws, drill pilot holes for the screws. Photo 1 shows how to assemble the frames. Set the top frame aside and screw the shelf boards to the shelf frame (Photo 2).

Assemble the Legs

- Drill five holes about 2 in. from the edge of the pegboard with the countersinking bit.

- Spread a bead of construction adhesive on the legs and attach the pegboard with 1-1/4-in. screws.

- Pro tip: If glue oozes through the holes, wait for it to dry. Then shave it off with a sharp chisel.

You’ll notice that the leg assemblies are 1/8 in. narrower than the inside dimension of the top. That’s so you can install the legs without binding, which would cause the pegboard to bow. Also, if the only pegboard you can find is thinner than the 1/4-in. pegboard specified, add the difference to the front and back of the shelf frame (C). For example, if you buy 1/8-in. pegboard, add 1/4 in. to parts C.

The pegboard is useful for hanging tools, but its real function is to stabilize the workbench as a brace. We added the construction adhesive to make sure the assemblies stayed strong and rigid. Be aware, though, that some of the adhesive will be visible through the holes.

The pegboard holes are a little too big to use as screw holes, so use a No. 6 countersink bit to drill pilot holes and make countersinks for the screws. Secure five evenly spaced 1-1/4-in. screws into each leg. Make sure you know how to install a pegboard.

Screw the Legs to the Top Frame

- Apply construction adhesive where the legs contact the top frame.

- Attach the legs with screws.

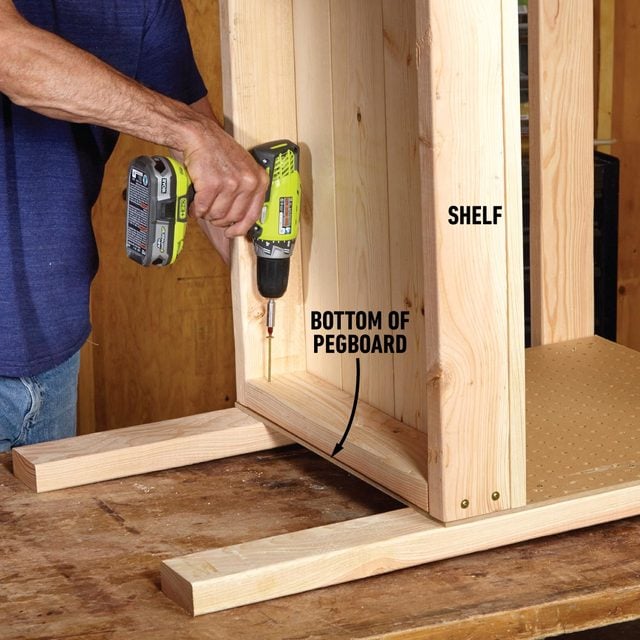

Add the Shelf

- Rest the bench on one end.

- Slide the shelf between the legs and line it up with the bottom of the pegboard.

- Screw through the shelf into the legs.

Mount the Top Boards

- Starting at the back, align the first 2×6 flush to the back and measure for the 2-in. overhang on the side.

- Attach the 2×6 with trim screws. Attach the rest of the boards the same way.

- Note: The front 2×6 will overhang the frame about 2 in.

- Stand the workbench on one end. Then it’s simple to slide the shelf into place and line it up with the pegboard.

- Drive 3-in. screws through the shelf frame into the legs to support the shelf.

- Note: The top of this bench is 2x6s, placed tight together. The boards overhang the frame 2 in. on the sides and front. The overhang makes it easier to use clamps on the edges of the workbench. We attached the 2x6s with trim screws, but you could substitute 16d casing nails.

Attach the Back Brace and Backboard

- Attach the 1×4 shelf to the 1×10 backboard.

- Add a 2×4 block at each end.

- Rest the backboard assembly on the workbench and drive screws through the back to hold it in place.

- Apply construction adhesive before attaching the brace with 2-in. screws.

- Note: The 1×10 back brace keeps things from falling off the back of the shelf, but it also stiffens the bench to prevent side-to-side rocking. The backboard is a 1×10 with a 1×4 shelf attached.

- On the side of the 1×10 you want facing out, draw a line the length of the board, 1-3/4 in. down from the top. This is where you’ll align the bottom of the 1×4.

- Draw a second line 1-3/8 in. from the top.

- Drill pilot holes with the countersink bit every 8 in. along this line.

- Ask a helper to hold the 1×4 on the line while you drive 2-in. screws into the shelf through the pilot holes.

- After the shelf and 2×4 blocks at each end are attached, screw the backboard to the workbench.