How To Join Galvanized to Copper Pipes

Updated: Jun. 27, 2024

Use dielectric unions to stop corrosion.

Varies

Intermediate

$50 - $150

Introduction

Water leaks from old galvanized steel water pipe are common at joints, especially when they're joined to copper. Use a dielectric coupling when fixing the problem to prevent further damage.Tools Required

- Adjustable wrench

- Hacksaw

- Pipe wrench

- Plumbers tape

- Soldering torch

- Tube cutter

Materials Required

- Copper pipe

- Dielectric union

- Flux

- Sandpaper

- Solder

- Steel nipple

Replace a Leaky Galvanized Steel Pipe

It’s far easier to make a repair to steel pipe with copper than with galvanized plumbing pipe, because the galvanized calls for cutting threads on exact lengths of pipe. But first, call your local plumbing inspector or water utility and ask for a pipe recommendation. The water in some regions is highly corrosive to copper, making plastic (CPVC or PEX) a better choice.

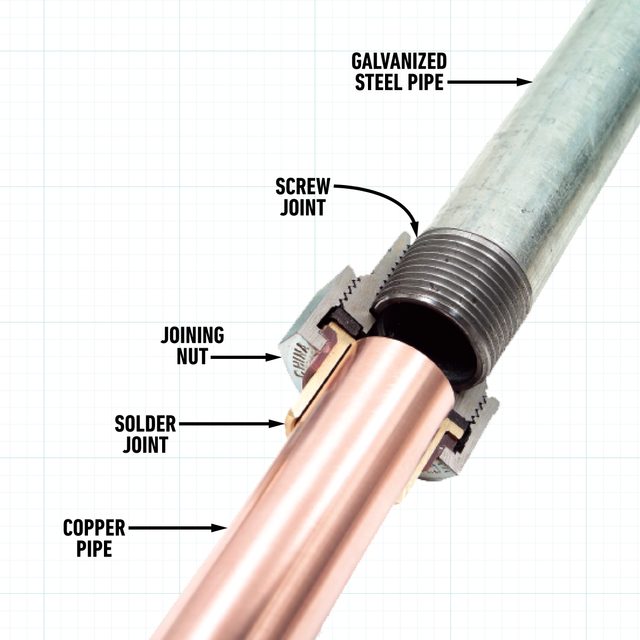

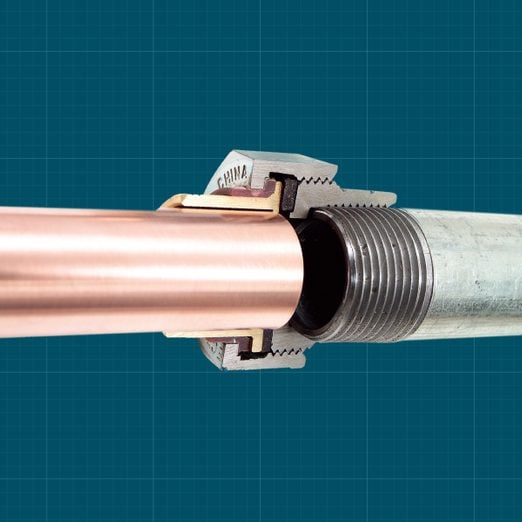

Also be aware that directly joining different types of metals — in this case, galvanized steel pipe and copper — can cause rapid corrosion at the joint (called dielectric corrosion).

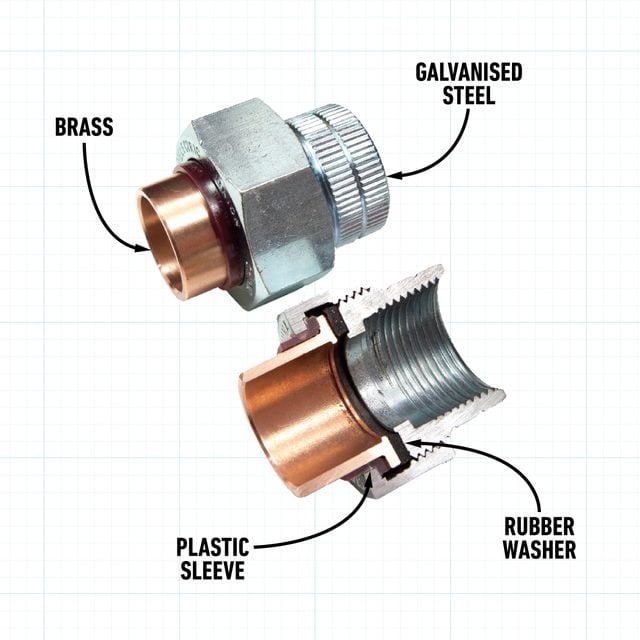

To limit this problem, make the steel/copper connections with special dielectric unions rather than with a regular coupling. This type of union separates the two metals with a rubber washer and plastic sleeve so they don’t actually touch each other.

Project step-by-step (2)

Remove the old joint

To remove the old leaky joint, turn off the water at the main entry, drain the system and cut the pipe near the joint with a hacksaw. With a pipe wrench, remove the pipe back to the nearest joints, working in both directions.

Check the joints to see if they’re clogged or badly corroded as well. If so, consider continuing back until you find a clean, solid fitting. Unfortunately, one bad joint often means others or much of the system needs replacing too.

Joining copper and steel

Add a new galvanized steel pipe length (nipple) at each end and solder in your copper. Use sandpaper as needed for cleaning the pipe. Then take the union apart and solder the brass end to the copper.

Screw the steel end to the galvanized pipe, using Teflon tape as needed. Finally, join the two ends with the large joining nut.