Give your skills a whole new spin.

2 hours

Beginner

$400

Introduction

Although lathes and turning tools have evolved through the centuries, the art of woodturning has remained the same: A sharp tool cuts a spinning piece of wood to create something beautiful and functional.

Turning is an incredibly satisfying form of woodworking that lets you create anything from spindles and handles to ornate bowls and hollow vessels. But to create the ornate, you first have to learn the basics. Let me show you how to turn a simple rolling pin using carbide lathe tools.

Watch How to Make an Elegant Rolling Pin to Use and Display

Tools Required

- Calipers

- Carbide Lathe Tools

- Sandpaper

Materials Required

- Any species of wood

Meet the Expert

Bitten by the woodturning bug at age 9, Joe Cruz has been creating useful art on the lathe ever since.

Be Aware of Lathe Safety

Long hair, jewelry and baggy clothes can all spell disaster when you’re working on a lathe. Keep your sleeves buttoned at the cuffs, take off any hanging jewelry and always tie back long hair. Always use eye protection or a face shield, and wear a dust mask to protect your lungs. A turning jacket is nice to have to store some lathe accessories but not necessary.

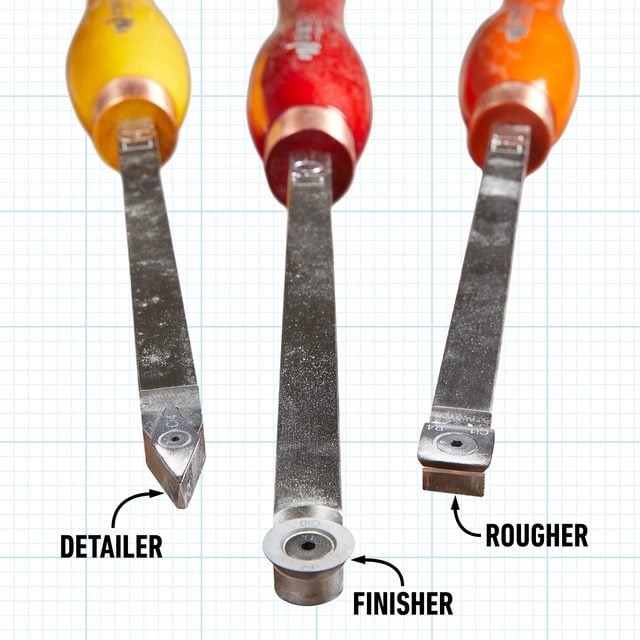

Choose the Right Tools

When I started turning, the only tool options were “traditional” high-speed steel ones like spindle gouges, bowl gouges, skews and scrapers. Today, the novice turner has a better choice: carbide tools.

Easy Wood Tools and Hunter Tool’s carbide tools flattened the learning curve so you can get to turning faster without purchasing (and learning to use) expensive sharpening equipment.

Woods to Use for Spindle Turning

Domestic hardwoods like cherry, maple and walnut are easy to turn and readily available. Exotic hardwoods like purpleheart, padauk and cocobolo produce beautiful turnings, but they’ll dull your tools faster and the dust may irritate your lungs and eyes.

PRO TIP: Shopping For Materials

Often you can find wood to turn in your scrap bin, but the tools and machinery are best found at specialty woodworking outlets like Rockler and Woodcraft.

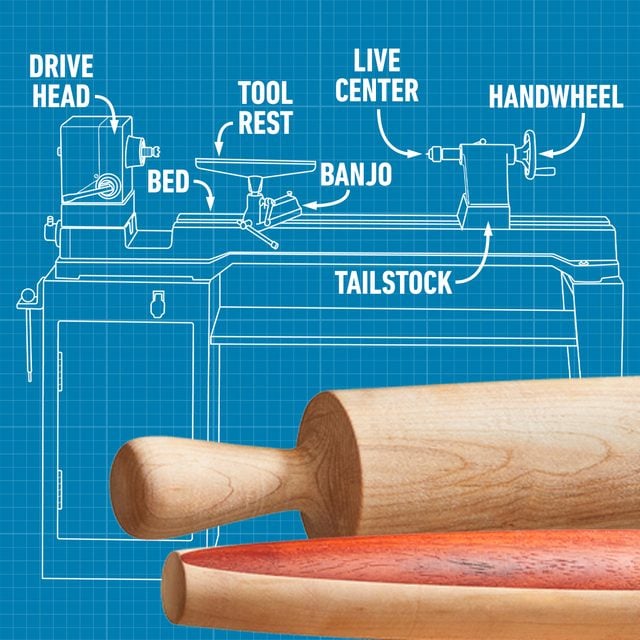

Parts of a Lathe

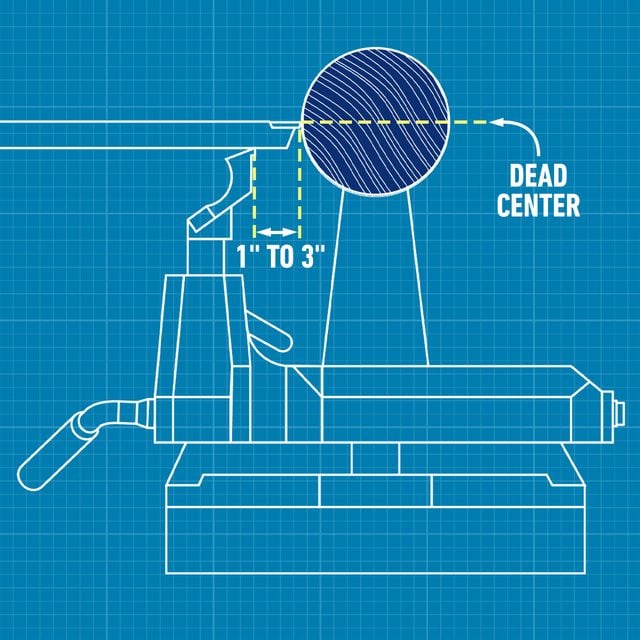

Set the Tool Rest

Carbide tools can be safely used with the tool rest three inches from the stock, but I prefer it a little closer. Adjust the banjo so the tool rest sits about an inch away from the turning blank. Set the height of the tool rest so the carbide cutter is dead center on the turning blank.

Spindle Turning Speeds

Use this chart to help you set the spindle speed of your lathe:

| Roughing | Shaping | Sanding | |

| Up to 2″ | 800 | 1,300 | 3,000 |

| 2″-4″ | 650 | 1,100 | 2,500 |

| 4″-6″ | 500 | 900 | 1,700 |

| 6″ | 350 | 700 | 1,000 |

Project step-by-step (10)

Mark the Center

On one end of your turning blank, draw two lines, corner to corner. Set your drive center on the intersection of these two lines and strike it with a hammer. Repeat this process on the other end. This creates impressions that will help you center the blank on the lathe.

Mount the Turning Blank

With the drive center mounted on the turning blank, slide the tapered end of the drive center into the drive head. Holding the blank with one hand, slide the tailstock up to it, aligning the live center to the impression. Lock down the tailstock to the bed and tighten the handwheel until the drive center and the live center are fully seated.

Rough Out the Turning Blank

With the lathe set to 650 revolutions per minute (rpm), slowly draw the roughing tool from one end to the other. Take shallow cuts to begin with, gradually increasing the depth of cut to about 1/8-inch. As you reduce the square stock down to a cylinder, remember to occasionally readjust the banjo so the tool rest stays close to the work.

Finish the Profile

For finishing the profile on a shape like this, I continue to use the roughing tool; the cutter head is slightly curved so it works well. For tighter curves, use the finishing tool. Increase the spindle speed to 1,100 to 1,300 rpm. Press lightly and move the tool across the work with a slow, steady speed until you’ve achieved the desired profile.

Cut for Parting

Easy Wood Tools does make a parting tool, but I prefer the detail tool to cut a groove in the spindle. Cut inward until there’s about 1/4-in. left to go. This will give you plenty of room for a slender saw blade when it comes time to completely part off.

Sand it Smooth

Set the spindle speed to about 2,500 rpm and quickly move the sandpaper back and forth across the rolling pin. Start with 120-grit sandpaper and work your way up to 320.

- Pro tip: It’s best to sand on top of the spindle with the lathe in reverse. The dust will fall down and away from you. My lathe doesn’t have reverse, so I hold my sandpaper from underneath — and hold my breath!

Apply a Finish

With your project still on the lathe, finishing is easy. Shellac and wax work well, but for rolling pins, mineral oil is a great choice. It’s food-safe and can be reapplied with ease.

Part Off the Rolling Pin

When the finish dries, it’s time to part off the rolling pin. Roll the spindle by hand and complete the part with a handsaw. Once it’s parted, sand the ends and touch up with finish.

- Pro tip: I prefer a unique type of saw, the Japanese-style pull saw. It’s thin and cuts on the pull stroke, making it easy to use on the lathe.

Adding Handles

Here’s how to lay out the handle profiles for a rolling pin. Follow these steps to make the handles symmetrical.

Lay out the handles

Define the length of the handles of your rolling pin with pencil marks on the cylinder. With the lathe on slow speed, rest your pencil on the tool rest and touch it to the wood. This will draw a line around the circumference of the blank.

Shape the handles

With the finishing tool, start at the outside and cut toward the deepest part of the profile. Once you’ve achieved the general shape, increase the spindle speed and finish the profile with extremely light cuts.

Show Your Stuff

Build a simple display rack

I made the back panel of the display rack from walnut because it contrasted well with my rolling pins. Cut the panel to an appropriate size, round over the edges and sand it to 220 grit.

Cut the pegs

The pegs can be simple straight dowels, but I took it one step further. Using a spindle sander, I made half-round saddles for the rolling pins to sit in. I mounted them to the panel with 1-1/4-in. screws from the back.

Apply a finish

Once the display rack is complete, apply your favorite finish. I went with a wipe-on gel urethane from General Finishes.