Drive Center

When turning wood on a lathe, each workpiece is mounted between the headstock (top) and the tailstock (bottom) with pointed attachments called centers.

A drive center (aka a spur center) is a sharp, multi-pointed attachment that fits into the headstock. It’s driven shallowly into the top end of the workpiece, holding it in place for turning.

Be sure to choose a drive center with a shaft size that matches your lathe. Lathe centers come with tapered shafts (usually two sizes, MT1 and MT2) and a springloaded end to avoid pounding it into your workpiece with a hammer.

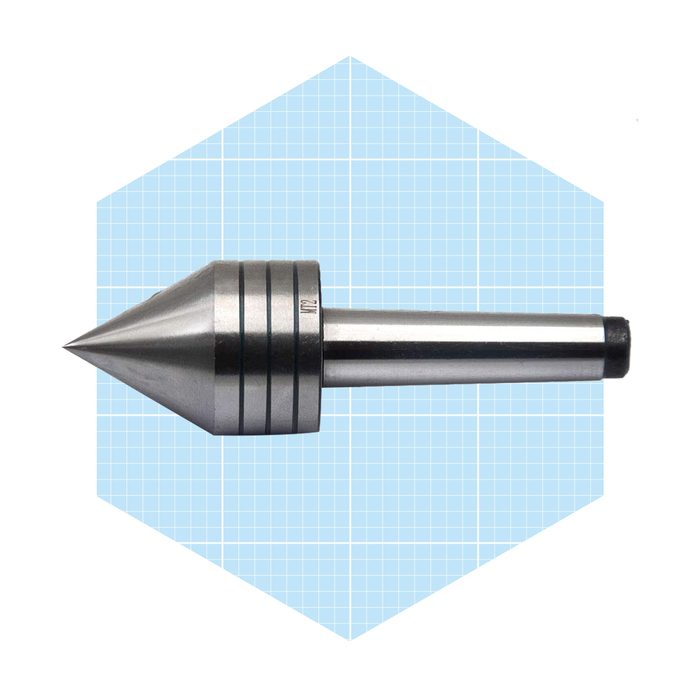

Live Center

In woodturning lathes, the tailstock features a second conical center called a live center. This cone-shaped piece of steel contains a bearing that lets it spin freely, supporting the bottom of a workpiece as it turns on the lathe.

As with drive centers, be sure to choose a live center with a tapered shaft size that matches your lathe’s configuration. It’s also wise to start with a medium-sized live center of around two inches in cone diameter.

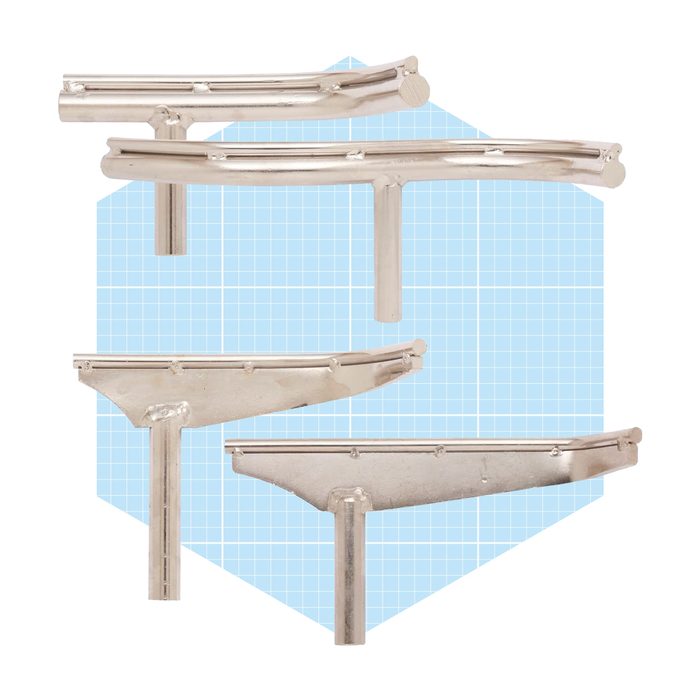

Tool Rest Platforms

As the name implies, a tool rest is a flat platform connected to the central bed of a lathe where you place tools as you work. These removable platforms come in various lengths, widths and shapes.

Different woodturning tool rest platforms work better for different shapes of projects. Not all are compatible with every lathe, so be sure yours matches before purchasing. It’s also worth noting that most woodworking lathes come with one or two basic tool rest platforms.

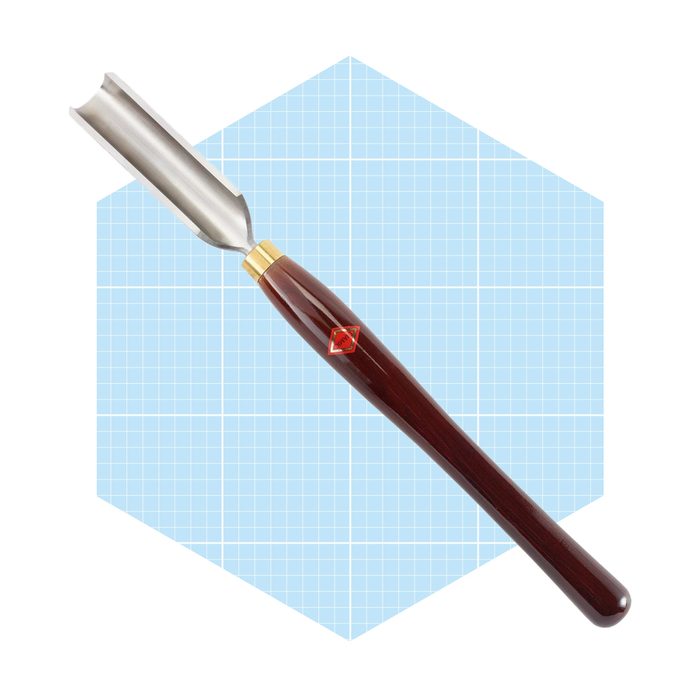

Roughing Gouge

Roughing gouges are large, beefy chisels with curved blades that remove large amounts of wood from the workpiece, bringing it closer to the desired shape.

Most woodturning projects begin with a roughing gouge, since it’s the fastest way to remove lots of wood in the early stages of turning. Choose a roughing gouge with a nice long handle (at least 12 inches) that’s easy to grip so you can angle it and apply leverage easily.

Parting Tool

Parting tools are similar to chisels, but flat and pointed on the end. They turn grooves in the workpiece, particularly near each end to separate the emerging project from the short waste sections connected to the headstock and tailstock.

They also help turn indicator grooves along the length of a workpiece that become cylindrical objects, like a chair leg or spindle. With the help of calipers, a parting tool can carve these indicator grooves to a precise diameter, showing you exactly how much more wood needs to be removed.

Bowl Gouge

Bowl gouges are traditionally large, curve-edged chisels with rounded ends. They’re mostly for rolling and shaping inside and outside curves on round projects like bowls during face turning (i.e. removing wood from the top or bottom of a workpiece rather than the side).

When selecting your first bowl gouge, choose one with around a 1/2-inch blade width and an elliptical blade end profile. This feature lets you use the tool in a wider range of curve-shaping situations.

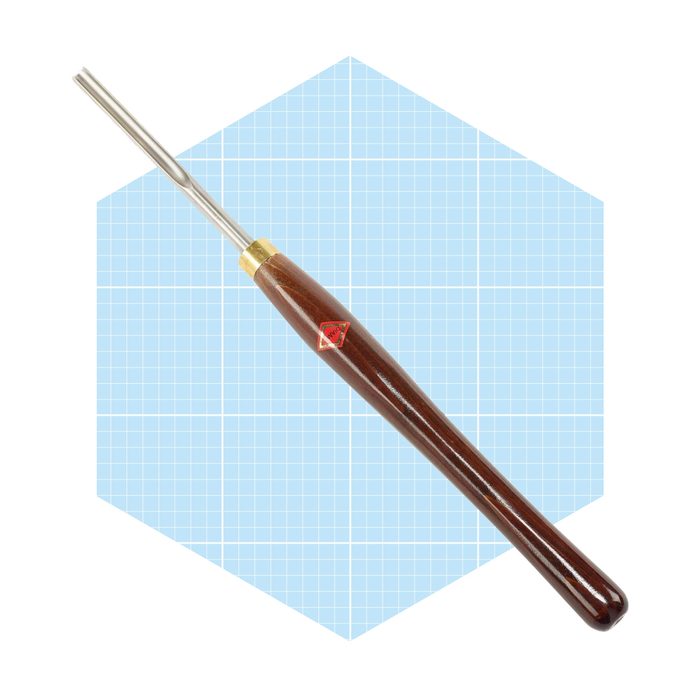

Spindle Gouge

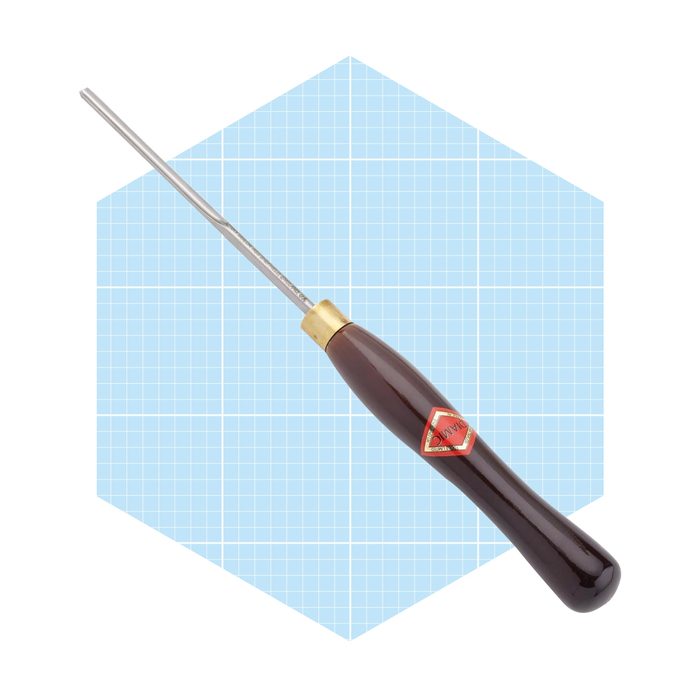

Curve-edged and rounded like bowl gouges, spindle gouges are a smaller and finer version. They’re meant for fine detail work on chair and table legs, spindles and other long, cylindrical workpieces.

Like bowl gouges, they can create different effects depending on pressure and blade angle. As with all lathe accessories, choose one with a long handle (at least 12 inches) that’s easy and comfortable to grip.

Lathe Calipers

Pincher-style lathe calipers precisely measure the thickness of objects that can’t be measured directly with a ruler or tape.

Similar in mechanics to needlenose pliers, calipers can be gently pinched down on either side of a cylindrical woodturning project for an accurate readout of its thickness. This is essential in precision work like turning chair or table parts. Be sure to choose calipers that can hold their position at a given thickness.

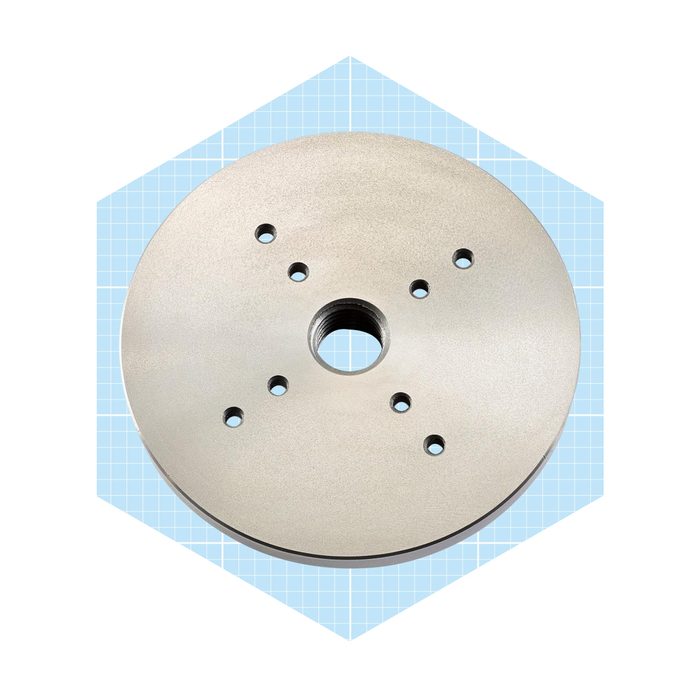

Face Plate

Face plates are circular center attachments that fit into the headstock. Meant for face turning, these come with a central shaft that fits into a hole drilled in the middle of the workpiece. Some face plates also have holes for additional screws, holding it even more securely to the workpiece.

Face plates are typically used for turning bowls or other objects where the mounting holes will eventually be removed.