Learn the basics of flattening rough-sawn wood.

1 - 2 hours

Intermediate

$1000-$2000

Introduction

Expand your woodworking skills and get access to a wide range of domestic and imported wood for your furniture projects by learning to flatten and plane rough-sawn lumber.

If you’re an aspiring woodworker wishing to move on to more advanced projects, there’s only one path: learning about planing rough-sawn wood.

Buying lumber that’s smooth on all four sides (known as S4S) at the home center will limit your project portfolio for two reasons. First, you’re stuck with 3/4-in.-thick stock. Advanced woodworking calls for a myriad of thicknesses only available in rough-sawn form. Second, it’s rare to find store-bought boards that are perfectly flat, straight and true.

It takes an investment to flatten wood, though. You can’t pull this off without a jointer, surface planer and table saw.

A basic 6-in. jointer will do most everything you’ll need. If you’re only doing small projects, you can get away with a 4-in. jointer for less money, but you can’t flatten wider boards. You need to keep the jointer and planer equipped with sharp knives. As for the table saw, any type will work fine, including portables.

Woodworkers all have their own system for planing wood, some of which are pretty complex. This is one simple method that’ll get you started. As you get comfortable with planing, you’re sure to develop your own.

Jointer Smarts

- Be persnickety and square the fence to the bed before any jointing. That’s the only way to ensure square sides.

- A rust-free polished bed and fence will give you much better results.

- When you’re jointing edges, move the fence every dozen or so passes to spread the wear over the entire edge of each knife.

Finding rough-sawn lumber

Rough-sawn wood is at least 1/4-in. thicker than equivalent S4S wood from the home center, allowing you to flatten and straighten it. It’s also cheaper. If you have a hardwood retailer or woodworking supplier near you, that’s great. If not, you can shop online. Many rural woodworkers, including pros, buy all their wood online.

Board thicknesses are always listed as “X/4.” A 4/4 board is 4- by 1/4-in., or 1-in. Always get 1/4-in. thicker than the finished thickness you’re after. If you need a 1-in.-thick final thickness, you should order a 5/4 board. Select widths that are 1/2-in. or so wider than the finished width.

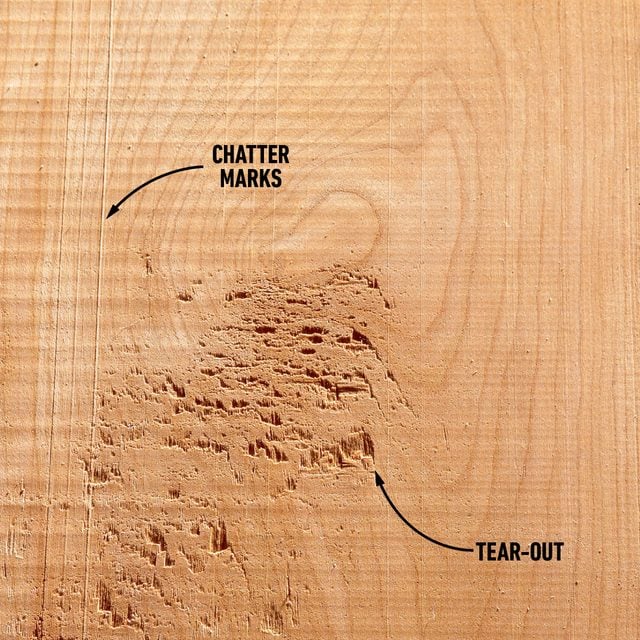

Dealing with tear-out while planing wood

Chatter and tear-out happens when the grain direction slopes up into the planer blades rather than away from them. Some woods are more prone to the problem than others. Changing feed direction and setting the jointer or planer as shallow as possible will usually help.

If you have tear-out or chatter during jointing, swing the board around and send the other end through first. If the tear-out is still there after the side is flat, let it go and send that side through the planer after the other side has been flattened. The planer gives a smoother cut than the jointer. If that doesn’t do it, you’ll just have to sand your way out of the jam.

Tools Required

- Safety glasses

- Square

- Table saw

- Tape measure

Materials Required

- Rough-sawn lumber

Project step-by-step (6)

Lay out the parts

Use chalk to lay out the parts you expect to get out of the board. Work around knots, cracks and edges with deep tree bark. If there are several parts coming from the same board, draw yourself a paper sketch to remind you of the layout.

Then cut the board to lengths corresponding to the parts. Cut each part at least two inches longer than the final length. Do so even if knots, checks or cracks are part of the waste at the ends. That will allow you to remove any checks on the ends of the boards or snipe (gouges) left over from the planer.

Don’t work with long boards unless they’re called for. It’s much easier to flattening short boards.

Flatten one side

First, sight down the board to find out if there’s a bow. Set the jointer depth at 1/32-in. or so and push the board through the knives with the bowed side up. You’ll hear the knives cutting off the high spots as you push it through.

Don’t worry about holding it tight against the fence. Keep most of the downward pressure on the board over the infeed bed of the jointer, with little or no pressure on the outfeed side. Keep making passes until the entire board is flat. When you’re making the last couple of passes, apply a bit more pressure on the outfeed side.

Flatten the opposite side

Send the highest point (at either end) of the board through the planer first, with a tiny cut. Sneak up on the cutting depth; there are likely to be high spots that might stall the planer as they come through the knives.

After the first pass, you can cut a bit deeper. But shallower passes will be less taxing on the tool and less likely to produce tear-out, stalls and burning. As with the jointer, swing the board around and send the other end through if you get any tear-out. Before you get to the final thickness, plane out any tear-out on the first side.

Flatten one edge

Sight the board to find any bows. Hold the board against the fence with the bowed side up and send it through the jointer just as you did for the sides. Stop when the edge is flat.

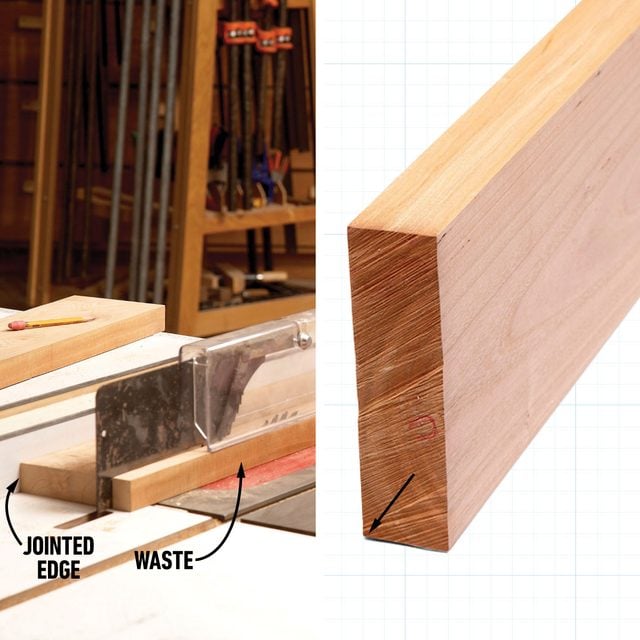

Rip away the waste

Place the jointed edge against the table saw fence and rip the board to within 1/8-in. of the final width.

Joint either edge to the final width

If the board is 1-1/2-in. or thicker, you can use the planer for this step. Or if you have several thinner boards of the same thickness, you can save time by planing all the wood all at once.

Hold the boards together as they enter and exit the planer. Cut the boards to final length and you’re ready to start your project!