This inexpensive faucet can save thousands in water damage—and prevent water contamination

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.Learn more.

This inexpensive faucet can save thousands in water damage—and prevent water contamination

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.Learn more.

A full day

Beginner

$51–100

Frost-proof, anti-siphon sill cock faucets prevent winter water-line freeze-ups and stop unsanitary water from contaminating the water system. Here's how to install one in your house.

In recent years, outdoor water faucets (sill cocks) and a water spigot have undergone two great improvements:

We’ll show you how to install freeze-proof sill cocks on an outdoor water faucet, anti-siphon valves and shutoff valves that will safeguard your home. The work will include connecting new fittings or soldering (also called “sweating”) copper joints. This is a great plumbing project to DIY.

Note: Our home has a galvanized piping system. The parts and installation techniques shown in the step-by-step photos are the same for copper plumbing. If you have a CPVC plastic system, however, the parts will look similar to those shown in Figure B (below).

When you upgrade a sill cock, call your plumbing inspector to check on local requirements. (You may need a permit, too.) Although plumbing codes and enforcement vary around the country, generally they require:

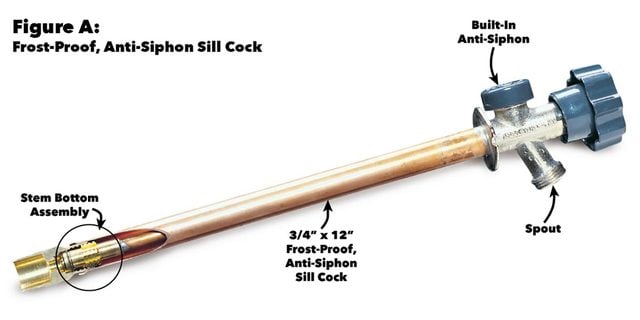

The frost-proof feature works by shutting off water flow back at the stem bottom (inside a heated space). The anti-siphon feature is built into the water spigot. Install the sill cock through a wall with a slight downward pitch to allow any remaining water to drain out through the water spigot.

If your home is built on a slab:

If your house is built on a concrete slab, a frost-proof sill cock won’t work in most cases. Instead, connect a standard sill cock that’s fitted with a vacuum breaker. If freezing is a concern, install a “stop and waste” valve on the pipe as close to the sill cock as possible (yet inside a heated area).

Build in an access panel so you can readily open and close the valve. In the winter, to avoid having your sill cock and pipes freeze, close the shutoff valve, uncap its drain to allow air to enter, and open the sill cock to let any water run out. Don’t change these fixture settings until warmer weather permits using the sill cock again.

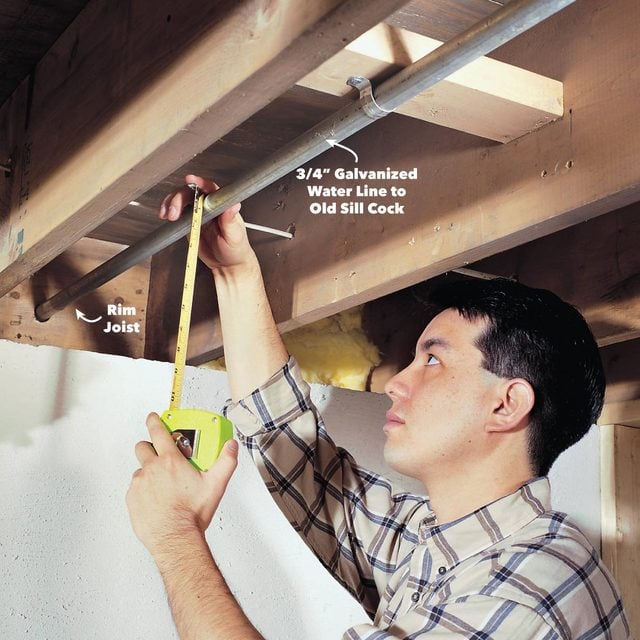

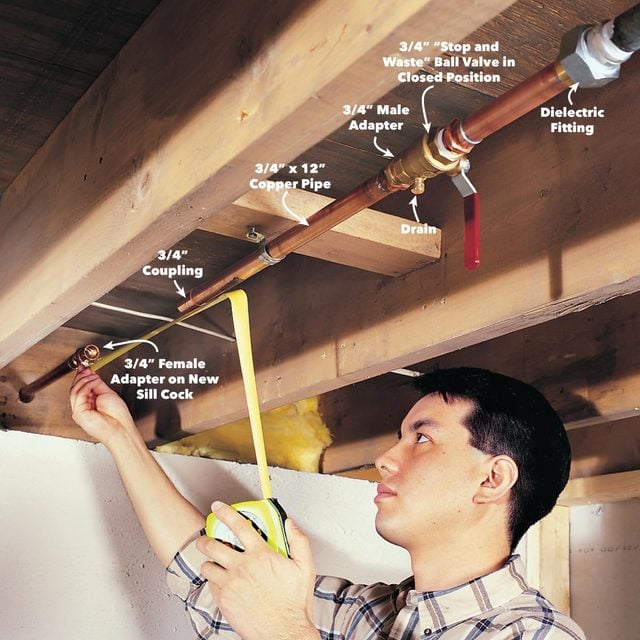

Measure your existing plumbing and list the inside diameter of the existing pipe, the thickness of the outside wall, the linear feet of new pipe and the types of fittings needed.

Draw where each pipe and fitting goes; indicate whether a part has threaded, sweat or solvent-welded joints; and label its size and description (for example, 3/4-in. copper female adapter). Then sketch the new plumbing layout to use for a materials list.

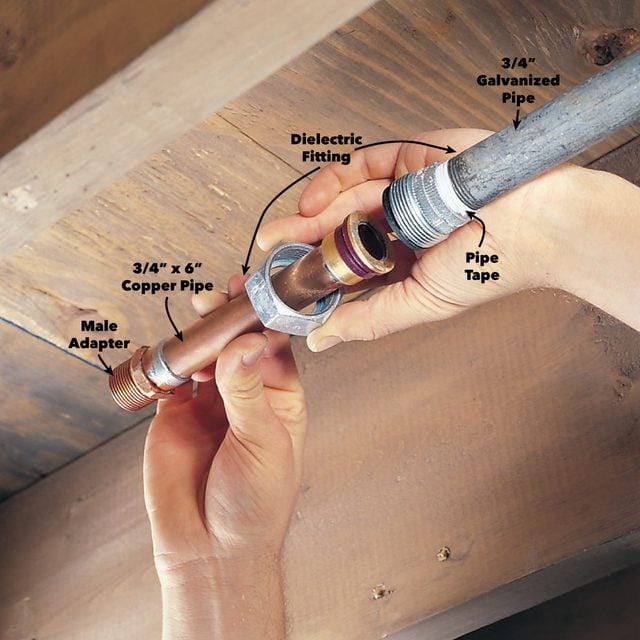

If you have galvanized pipe, we recommend you unscrew the pipe back at the first coupling or fitting (steps 3 – 6). Then insert a dielectric fitting (step 8) and convert to copper pipe and fittings all the way back through to the sill cock.

Frost-proof, anti-siphon sill cocks are available in 1/2-in. and 3/4-in. inside diameters, and 8-in., 10-in. and 12-in. lengths (step 7). Choose the diameter required by your local code and a length that will accommodate the thickness of your outside wall plus give you some working room inside to attach pipe and fittings.

We also installed a 3/4-in. “full-port” (for unobstructed water flow) ball valve with drain. There’s no neoprene washer to wear out, and the easy-to-turn handle shows whether the valve is open or closed (step 9).

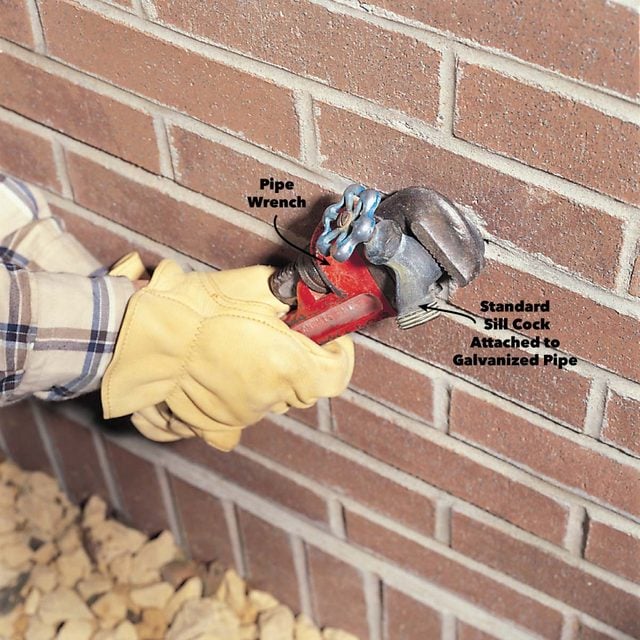

Turn off either the water shutoff valve to the existing sill cock or the main water supply. Open the sill cock and drain the water from the line. Remove the old outdoor water faucet sill cock by positioning a pipe wrench at the back of the sill cock and turning the wrench counterclockwise. Have an assistant use a pipe wrench to hold back the sill cock supply line inside to prevent sections of pipe from unscrewing.

Unscrew the old pipe at the joint closest to the outside wall. Hold one side stationary with one pipe wrench and twist off the pipe with the other. Remove as many couplings and pipes as needed to fit in the new assembly (step 8).

Bore a 1-1/8 in. hole (if the hole needs enlarging) for the new sill cock using a masonry hole saw. Dry-fit the sill cock in an upright position tight against the wall and mark the location of the fastening holes. Drill two 1/4-in. holes with a masonry drill bit and push the plastic screw anchors in flush to the wall. Apply a thick bead of clear silicone around the back of the sill cock flange, push it against the wall and fasten it with two 1-1/4 in. No. 8 roundhead brass screws.

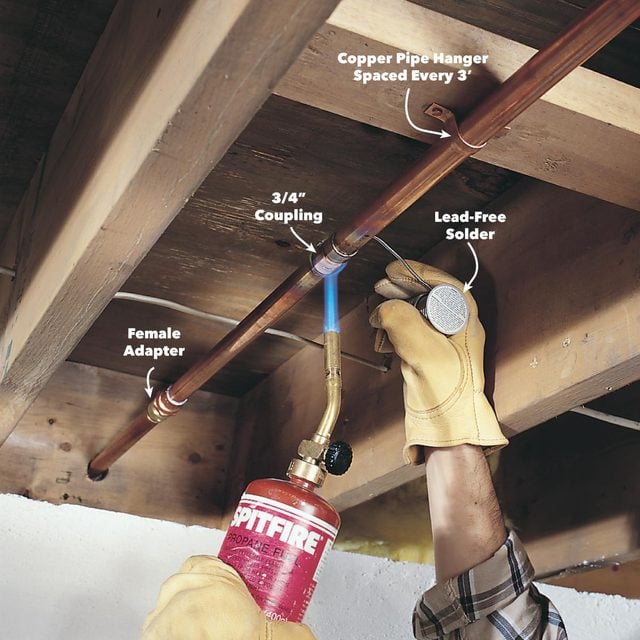

Start from the old pipe end and work toward the new sill cock. It’s easier to solder copper fittings to copper pipe and then screw them into hard-to-sweat parts like the ball valve and sill cock.

Disassemble the dielectric fitting and solder one end to a 6-in. copper pipe. Cool the pipe and reassemble the fitting. Then solder the copper male adapter to the other end. Apply pipe tape to the threads of the galvanized pipe and tightly screw the dielectric fitting to the pipe.

Apply pipe tape to the male adapter threads on the 6-in. pipe (shown in the previous step), and screw the “stop and waste” ball valve to it. The water flow direction arrow on the valve must point toward the sill cock. Solder a male adapter to a 12-in. copper pipe, apply pipe tape to the adapter threads and screw it into the other side of the ball valve. Temporarily screw a female adapter to the sill cock and slide a female coupling halfway onto the end of the 12-in. pipe. Then measure the distance between them, add 1 in. and cut a section of 3/4-in. copper pipe to fit.

Solder on the 3/4-in. coupling last. Remove the female adapter and solder it to the copper pipe. Then apply pipe tape to the male threads, and screw the adapter onto the sill cock. Solder both copper pipes into the coupling. When sweating the copper joints, open the sill cock, hold the torch on one side of the connection and the lead-free solder wire on the other side. Heat the joint for 10 seconds until the solder melts and flows around the connection. Loosen the pipe hangers along the pipe system to allow maximum movement to fit this last connection.

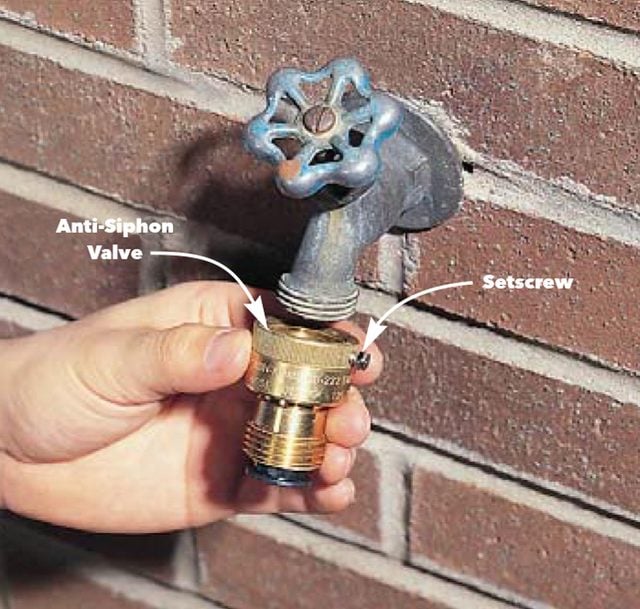

Depending on how your outdoor water faucet sill cock is currently plumbed, you may find that purchasing and installing an anti-siphon valve (also called a vacuum breaker) is all you need. Don’t apply any pipe tape or compound on the sill cock spout threads. To prevent accidental removal or tampering by vandals, all plumbing codes require that vacuum breakers be permanently installed. The breaker you buy will have either a setscrew (with a break-off head) that grips the spout threads or a feature to make it hard to unscrew the breaker once it’s installed.

If you have a CPVC supply system (as shown above in Figure B), omit the dielectric fitting, buy a plastic shutoff valve (with drain) and solvent-weld the pipe and fittings together. Position the valve so that its water flow direction arrow points toward the outside wall.

For the best results: