Have you seen power tool ads and wondered what exactly is a brushless motor? If so, here's a quick definition and an overview of the pros and cons.

What Are Brushless Motor Tools and Are They Right for You?

If you’ve ever shopped for a cordless power tool, you’ve no doubt seen advertisements touting brushless motors. So, just what is a brushless motor, and is it worth the added price?

Brushed direct current (DC) motors are the older technology, in use since the 19th century. The first brushless DC motor didn’t come along until 1962. Originally prohibitively expensive, brushless motor technology has finally come within reach of a DIYer’s budget.

Whether you’re shopping for a new tool or simply wondering what a brushless motor is, here are the facts, plus a checklist to see if brushless motor tools are right for you.

On This Page

What Are Brushless Motors?

To understand brushless motors and their advantages, we need to briefly talk about brushed DC motors.

Both brushed and brushless motors have two primary sections: a rotor and a stator. As their names imply, the rotor rotates while the stator is static and unmoving.

The motor functions by passing a charge through a looping wire, generating a temporary magnetic field. Because magnetic fields attract and repel other magnetic fields, the rotor will turn to align with the stator’s magnetic field. As the current passes through successive wire loops, the turning accelerates, spinning the rotor faster and faster. That ultimately results in the turn of a drill or the whirl of a vacuum.

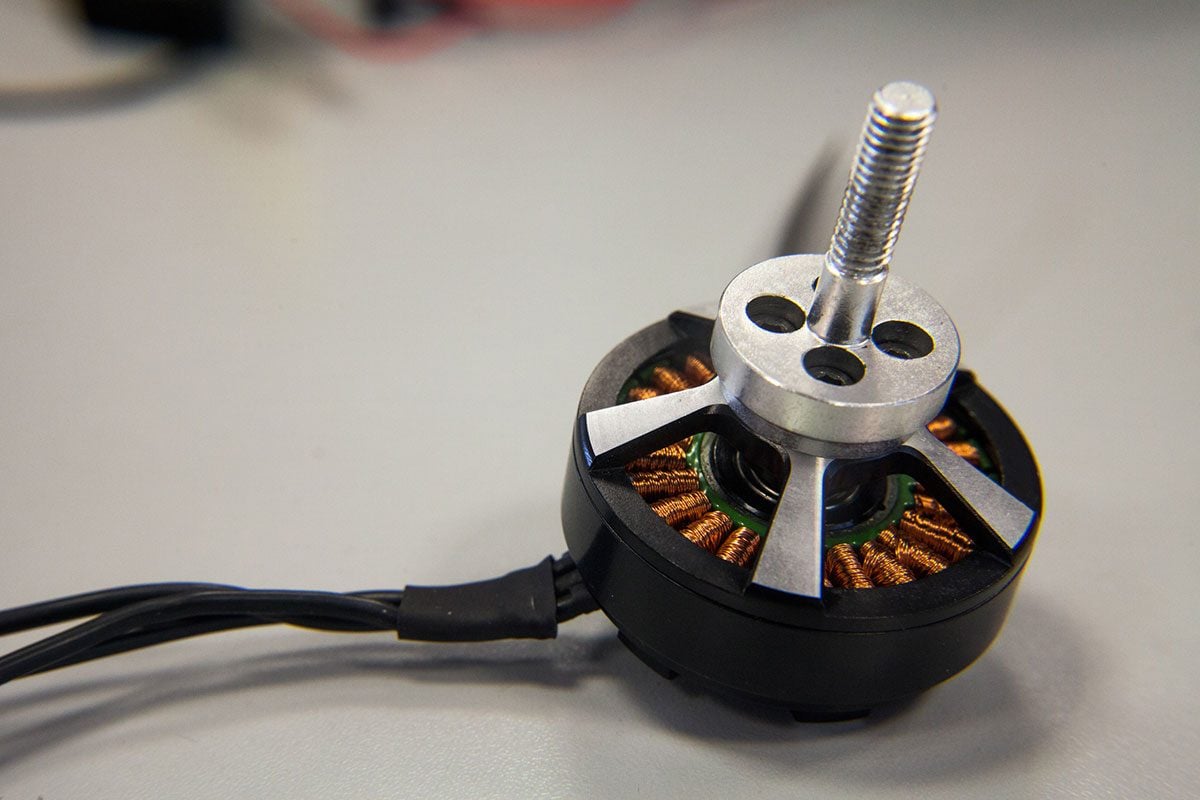

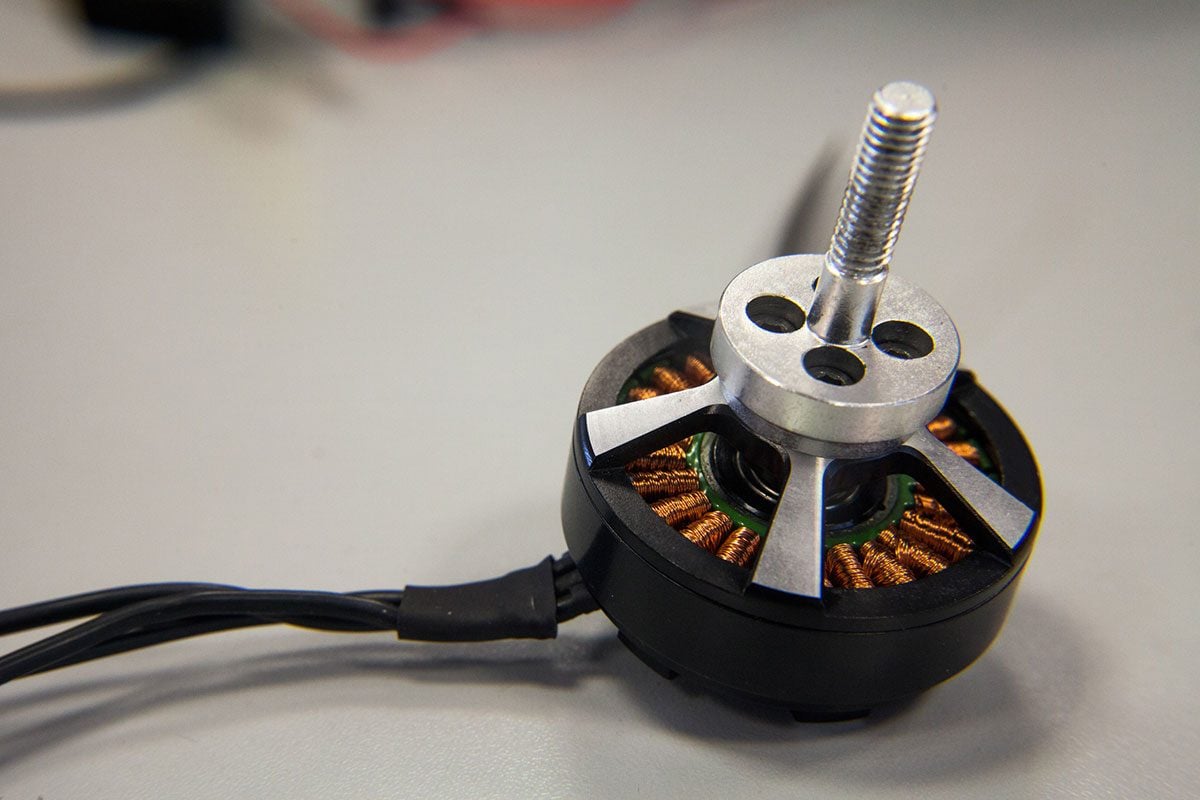

In a brushed motor the wires are wound around the rotor, while a brushless motor has its windings in the stator.

Charging the rotor coils requires a conductor to physically touch the ends of each wire in rapid succession. Those conductors are called “brushes.” In power tools they’re most often spring-loaded squares of carbon or graphite. The repeated contact with the rotor (specifically on a part called the commutator) generates friction and heat, and it’s only a matter of time before the brushes wear down to nothing.

Brushless DC motors (BLDCs) run a charge through windings positioned around the stator, rather than the rotor. Because the windings on the stator aren’t moving, they can be permanently connected to the motor, with no need for a brush to make the connection.

Brushless Motor Advantages

Brushless motors have a number of advantages over their brushed counterparts.

Lower Maintenance

Brushes eventually wear down due to friction, resulting in sparking, inefficiency and ultimately a non-functioning motor. Eliminating brushes eliminates a major point of tool maintenance.

Less Heat

In addition, the energy lost to friction is eliminated, and the friction-generated heat is no longer a concern. Some manufacturers point out that BLDCs also produce slightly less noise. While that’s true, it only applies to the motor itself — operating a brushless hammer drill is still going to be loud.

Lighter

Brushless motors can operate with smaller magnets. This results in lighter weight. That’s a huge advantage when working with a drill or other tool that might be held overhead or at an uncomfortable angle.

Efficiency

Brushless motors need more complex circuitry to properly sequence charges to the windings. But that same complexity also allows the motors to be more dynamic, responding to resistance and only drawing as much current as needed. For example, a brushless driver/drill can use less energy when drilling into plastic than into hardwood. This is why manufacturers often tout the “smart” properties of brushless tools.

Brushless Motor Disadvantages

These are the downsides to brushless motors.

Cost

The disadvantages of brushless motors all boil down to the added complexity of their design. BLDCs require a switching controller to sequence the proper charge through the stator coils. This makes them more expensive to manufacture, which is reflected in a higher initial cost.

Complexity

Added complexity also means a higher chance of failure. We weren’t able to find any studies comparing the failure rates of brushed vs. brushless power tools, but it’s generally accepted that more complex equipment is more likely to have something go wrong.

Are Brushless Motors Worth the Extra Cost?

In general, the tools that will see the biggest benefit from brushless motors are those that see long-term or continuous use.

To determine if a brushless tool is worth the investment, ask yourself the following questions:

- Will you use this tool for long stretches at a time?

- Is the size and weight of this tool important?

- Is performing maintenance or changing the brushes something you’d like to avoid?

- Do you want a cordless tool that lasts as long as possible on a single charge?

- Do you want a tool that produces less heat?

If you answered yes to several of the above questions, or if one of them is a must-have, then the extra cost for a brushless motor will likely be worth it. But if you just need an affordable tool for occasional use, make your decision on price and comfort, and don’t focus on whether it’s a brushed or brushless motor.