Stop drafts cold at electrical boxes with these easy foam outlet insulation tips.

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.Learn more.

Stop drafts cold at electrical boxes with these easy foam outlet insulation tips.

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.Learn more.

A few hours

Intermediate

$20-50

Many homeowners install plain foam gaskets between electrical cover plates and the switches/receptacles. However, those gaskets don’t always seal well. Infrared thermograph images of those outlets will show cold air still entering the house (which means warm air escaping).

Here are 10 ways to insulate your home without opening up walls.

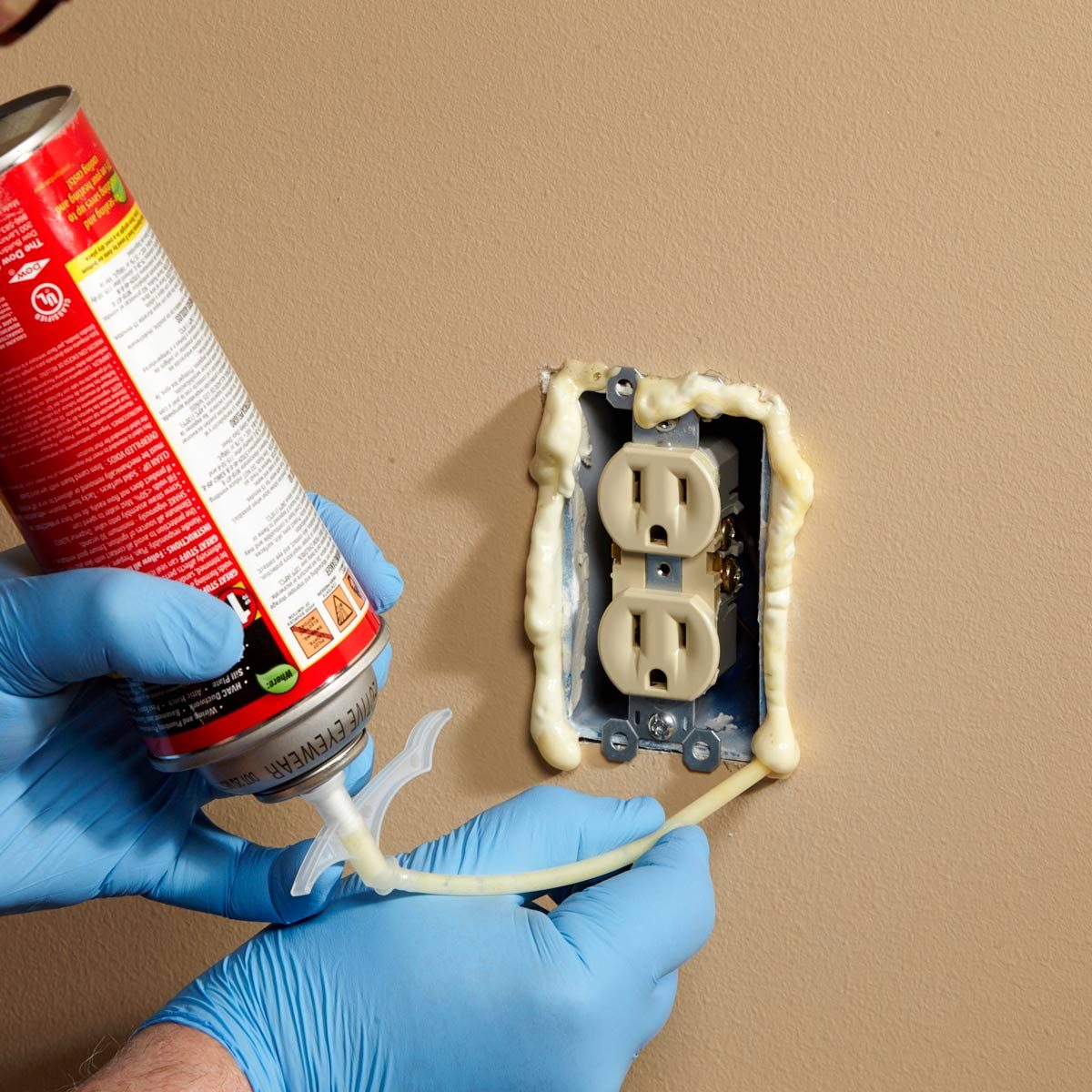

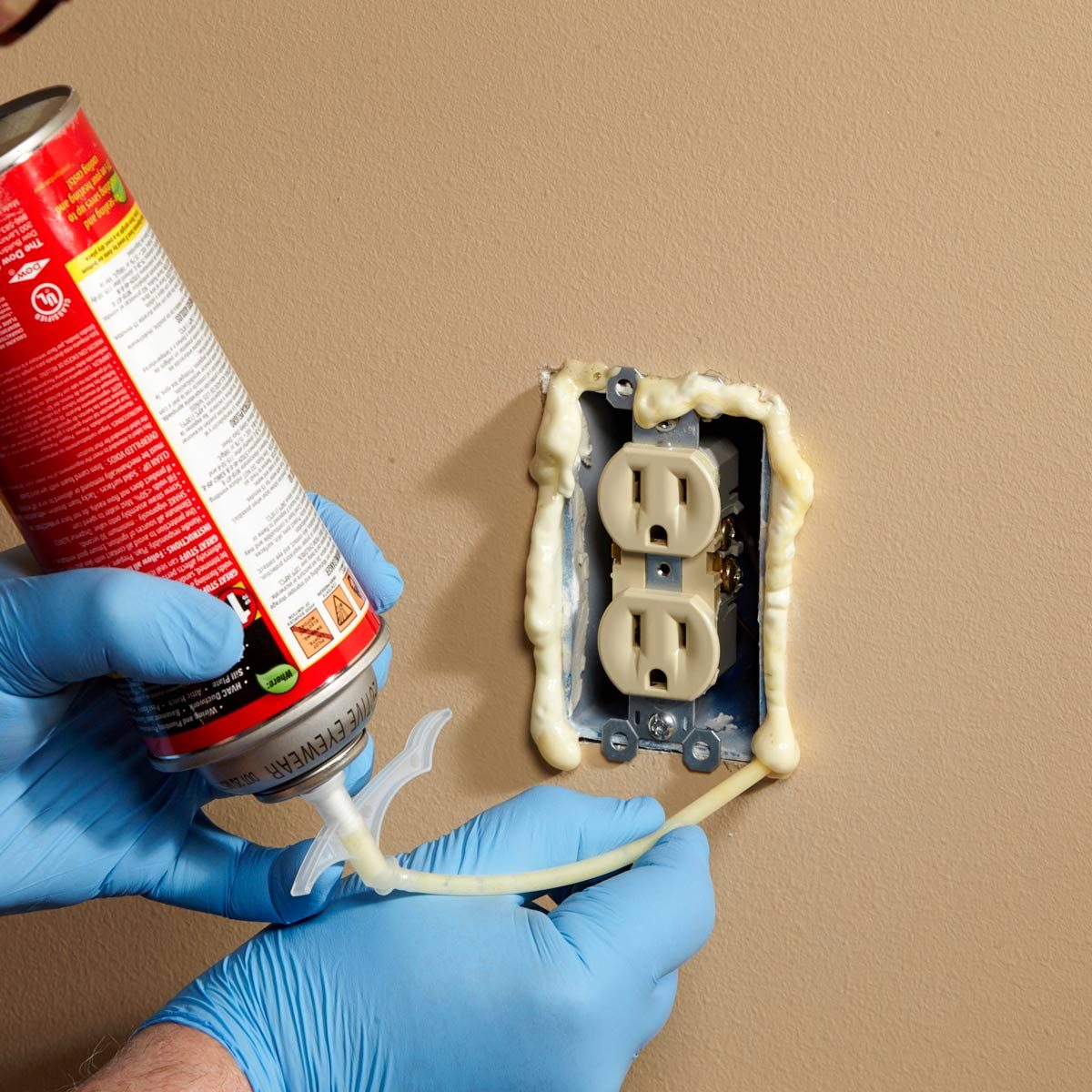

We’ll show you more effective methods that permanently seal those leaks. Sealing is easy to do and you can complete the entire house in about four hours. The materials cost less than $25, one of the best investments you’ll ever make! All you need is a caulk gun, caulk and aerosol foam. Here’s how to do it.

Gaps around ceiling boxes must be sealed with an intumescent fireblocking caulk or foam. Ordinary spray foam burns too quickly, opening the gap and creating a chimney effect that feeds the fire. Intumescent caulk or foam, on the other hand, swells when heated so it prevents that airflow. Regular caulk or foam outlet can be used on wall-mounted boxes.

If the electrical boxes aren’t mounted flush with the drywall, adding a box extender will make them easier to seal. They’re available at most home centers for single, round and multiple-gang boxes.

Plus, here’s how to install cove lighting.

Up next, here’s what you need to know about smart light switches.