Drywall comes in many different sizes. Learn how to choose the right drywall size and drywall thickness for your next project.

A Guide to Drywall Sizes

Which Drywall Size and Drywall Thickness Works Best?

Most people probably picture the standard 4×8 panel when they think of drywall, even though it’s by no means the only size or type of drywall available today. Panels come in a wide variety lengths, widths and drywall thicknesses. There are also “special use” panels, including moisture/mold-resistant, fire-resistant, and impact or abuse-resistant. Which size drywall you choose to hang can make a big difference in the final appearance and lasting quality of a finished wall assembly. This guide to drywall outlines what works best for me.

Myron Ferguson is a drywall and building performance contractor. He is the owner of Ferguson Drywall Innovations, Inc. and is from Middle Grove, NY

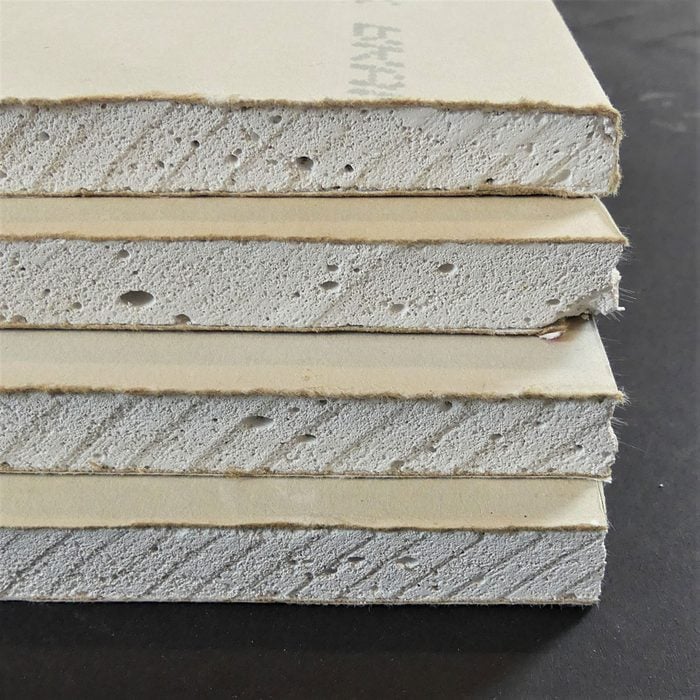

Drywall Thickness

Panels are available in four drywall thicknesses—5/8-inch, 1/2-inch, 3/8-inch, and 1/4-inch. (above are all 5/8-inch). Each drywall thickness has specific applications and framing requirement. The 3/8-inch and 1/4-inch panels are only available in shorter lengths. Regular 1/2-inch drywall thickness was the most commonly used drywall in new residential construction and remodeling. But, lightweight drywall is rapidly replacing this heavier drywall thickness.

Why Use Lightweight Drywall?

Working with drywall is hard work, in large part because it is heavy! A sheet of regular 1/2-inch drywall thickness weights about 60 pounds. The new lightweight drywall weighs about 41 pounds. A drywall hanger can hang an average of 60 4×8 sheets a day. If the hanger is installing regular drywall, that adds up to about nine tons a week. Installing lightweight drywall will reduce that amount down to six tons. That’s still a lot, but having to lift three tons less every week will increase production and decrease the risk of injury.

Lightweight drywall is also a little stronger, which means less damage to the edges when handling and more resistance to sagging. Lightweight panels meet all International Building Code, International Residential Code and ASTM C1396 Specification for Gypsum Board, for both 1/2-inch gypsum wallboard and 1/2-inch gypsum ceiling board.

Because of the superior sag resistance, compared to regular 1/2-inch drywall thickness, lightweight is ideal for ceilings that have joists 24-inches on center. Regular 1/2-inch drywall has always been approved for use on 24-inch spacing on ceiling framing, but because of heavy sagging insulation, wet ceiling textures, or higher humidity, either a 1/2-inch ceiling board or 5/8-inch drywall was usually the best choice. But now a 1/2-inch lightweight product can be used throughout the job. That means there’s really no reason to be lugging around those 70-lb. 4×8 sheets of 5/8-inch drywall.

Lightweight Drywall Pros and Cons

The new lightweight drywall looks the same as regular drywall; the screw spacing is the same; the paper face is the same, and it scores and cuts the same. The drywall supply yards are big fans of lightweight drywall thickness, because it doesn’t sag as much when forking it around, and the lighter weight causes less wear and tear on their delivery trucks. And of course, it’s lighter!

Lightweight drywall has a harder core, so utility knives do become dull more quickly when used to cut drywall. And a drywall rep recently told me that because the lightweight drywall has less mass, it’s not as good of a product for sound control as the old version. Not sure what the difference in the STC rating is exactly, but it is something to think about.

Lightweight panels are available in standard lengths, including 8-foot, 10-foot, 12-foot, 14-foot and 16-foot panels, and come in both in 48-inch and 54-inch widths.

Why Use Different Lengths?

Most 5/8-inch and 1/2-inch panels are available up to 16-feet long. Longer lengths help eliminate or reduce the number of butted seams, or butt joints. A butted seam is created when the ends of the panels are butted together. Butted seams are unavoidable when the wall or ceiling is longer than the available length of drywall. It’s always best to avoid butted seams. Unlike the sides of panels, the ends are not tapered, so hiding a butted seam is more difficult when taping the drywall.

I have visited a lot of drywall jobsites over the years, and I would say that most of the jobs were stocked with just 12-foot lengths. I experienced this when I was out in Eagle Colorado last winter, and we had ordered my usual variety of lengths and all that showed up was 8-foot and 12-foot lengths. The supplier said that was all they stocked because that was all anyone ever asked for.

I prefer using a variety of lengths because I end up with less butted seams. I also believe that ordering a variety of sizes produces less waste and saves time. For example, if I’m planning to hang drywall on a wall measuring 13 feet long, I will order two 14-foot sheets and end up with two 12-inch scraps. If I only had 12-foot sheets available, I would most likely have to cut the length to hit a stud, and then I would have to cut and fit the pieces which would be carved out of another 12-foot sheet.

It would take more time to hang the wall using 12-foot sheets. Plus, it would take longer to tape the additional butted seams. And oh yeah, there are butted seams that could have been avoided.

It’s true that ordering fewer sizes does make a job easier to estimate and easier to stock for the delivery guys. And the argument could be made that having the length you need always nearby would save time. But less butt joints is less butt joints, even if time saving is a wash.

Why Use 54-inch Drywall?

Again, the less seams/joints the better. When hanging drywall on walls that intersect eight-foot (or lower) ceilings, two four-foot-wide panels of drywall hung horizontally results in just one seam running the length of the wall. But more and more homes are being constructed with nine-foot ceiling heights, which means that four-foot-wide drywall creates two horizontal seams on each wall.

A common drywall mistake is failure to minimize seams on the wall. The best way to avoid the extra seam is to use 54-inch-wide panels. These wider panels are available in regular drywall as well as moisture, mold and fire-resistant panels.

NOTE: Not all drywall suppliers are going to stock the longer lengths or even some of the more specialized types of drywall, but if you plan far enough ahead, and if large enough quantities are needed, most products can be special ordered.