There may be times when you need to install some electrical conduit as part of your project. The following tips will help you choose the right type.

What to Know About Electrical Conduit Wiring

As a master electrician, I can admit to having an affliction. It’s one I share with most electricians: We like looking at all of the electrical wiring around us! When I’m in a restaurant or coffee shop with an open view of the structural ceiling, I can’t keep myself from looking up at all the wiring.

I can’t help but admire the work of others! That’s about the time I get poked in the ribs by my wife to stop looking up at the ceiling.

There may be times at home when you need to install some conduit for an outdoor project, or to provide some robust physical protection for some Type NM-B cabling in your garage or on your concrete basement walls. Maybe you need to install some flexible conduit for making a connection to an appliance.

I counted more than twenty types of conduit, tubing and raceway in the National Electrical Code (NEC). Let’s just focus on the “Top Ten” commonly available at home centers and hardware stores that you can install at home.

What Is Electrical Conduit?

Electrical conduit is best described as a raceway of circular cross-section used for the physical protection and routing of conductors (wires) and cables.

The term raceway broadly includes any enclosed channel, of any shape, that holds wires and cables. These include conduit and something called tubing, defined as a “thinwall” raceway of circular cross-section.

Types of Electrical Conduits

Conduit and tubing are sold in straight 10-foot lengths, in sizes ranging from 1/2-inch up to two inches. (Larger sizes, up to six inches, are used in commercial and industrial settings.)

Flexible conduit is sold in various convenient lengths, usually coiled and wrapped in plastic packaging. Flexible conduit also comes in various sizes, but 1/2-inch, 3/4-inch and one inch are the most common. Some conduits, tubing and raceways are made from metal, and many have equivalent nonmetallic (PVC) versions.

Some important reminders:

- In all cases, it’s essential you use the appropriate connectors, couplings and fittings that match the type of conduit or tubing you’re installing.

- Don’t mix and match electrical conduit and fittings with plumbing pipe and fittings. They often look similar and might screw or glue together, but electrical materials and plumbing materials are designed for distinctly different purposes.

- Unlike factory-made electrical cables where the insulated wires are already installed within the cable jacket or sheathing, when you’re done installing your run of conduit, you need to pull or push your own insulated wires into the conduit. You can use a fish tape or a small rope for pulling wires into the conduit.

- In general, conduit, tubing and raceways should not be filled to more than 40% of their cross-section. Overcrowding of wires in conduit could result in overheating, wire insulation failure and a fire or shock hazard.

- The total degrees of bends in a conduit run must not exceed 360 degrees between pull points. Too many bends result in a harder pull, which in turn may cause damage to the wire insulation. You can always add a junction box or conduit fitting (with a removable cover) to make your wire pulls easier.

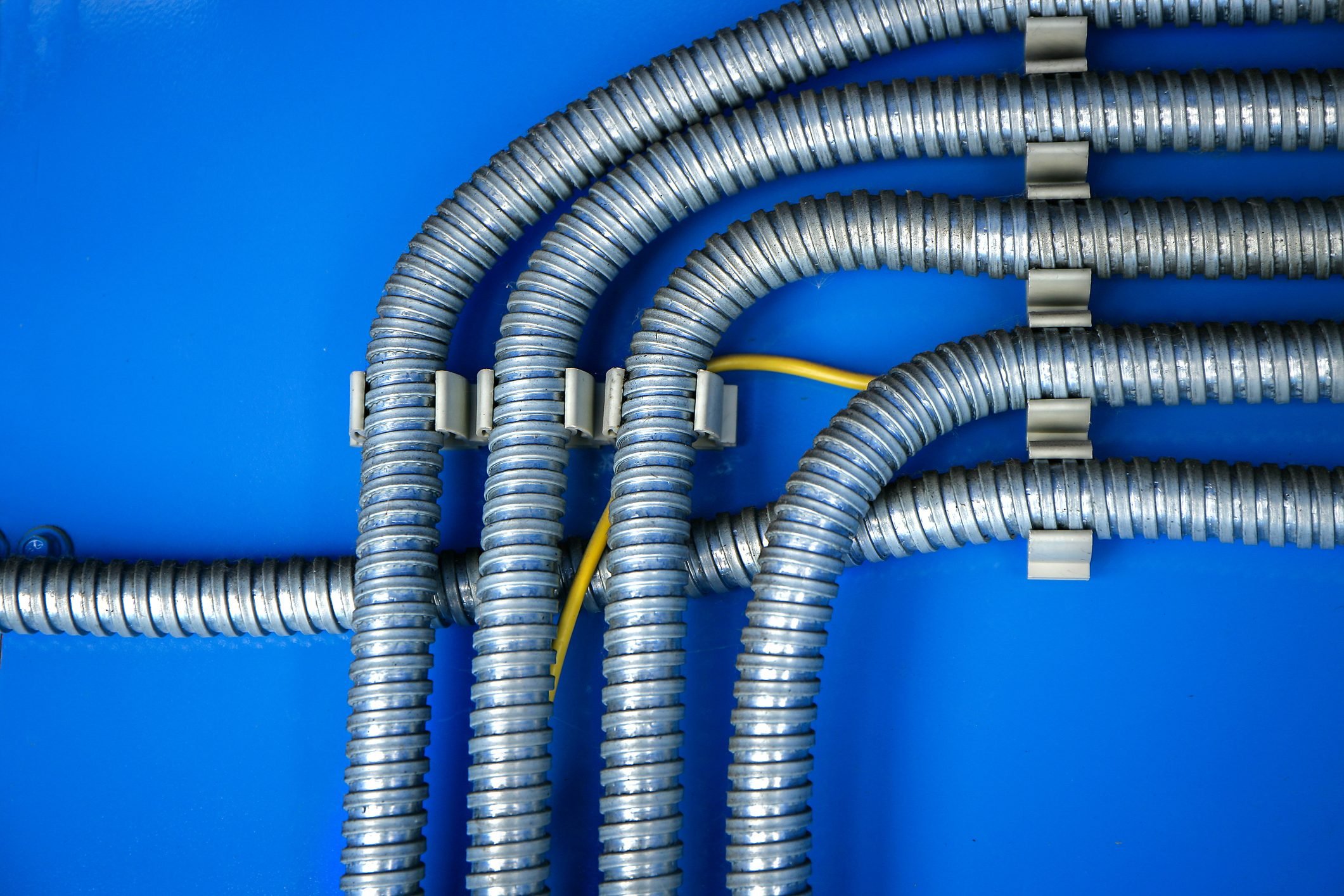

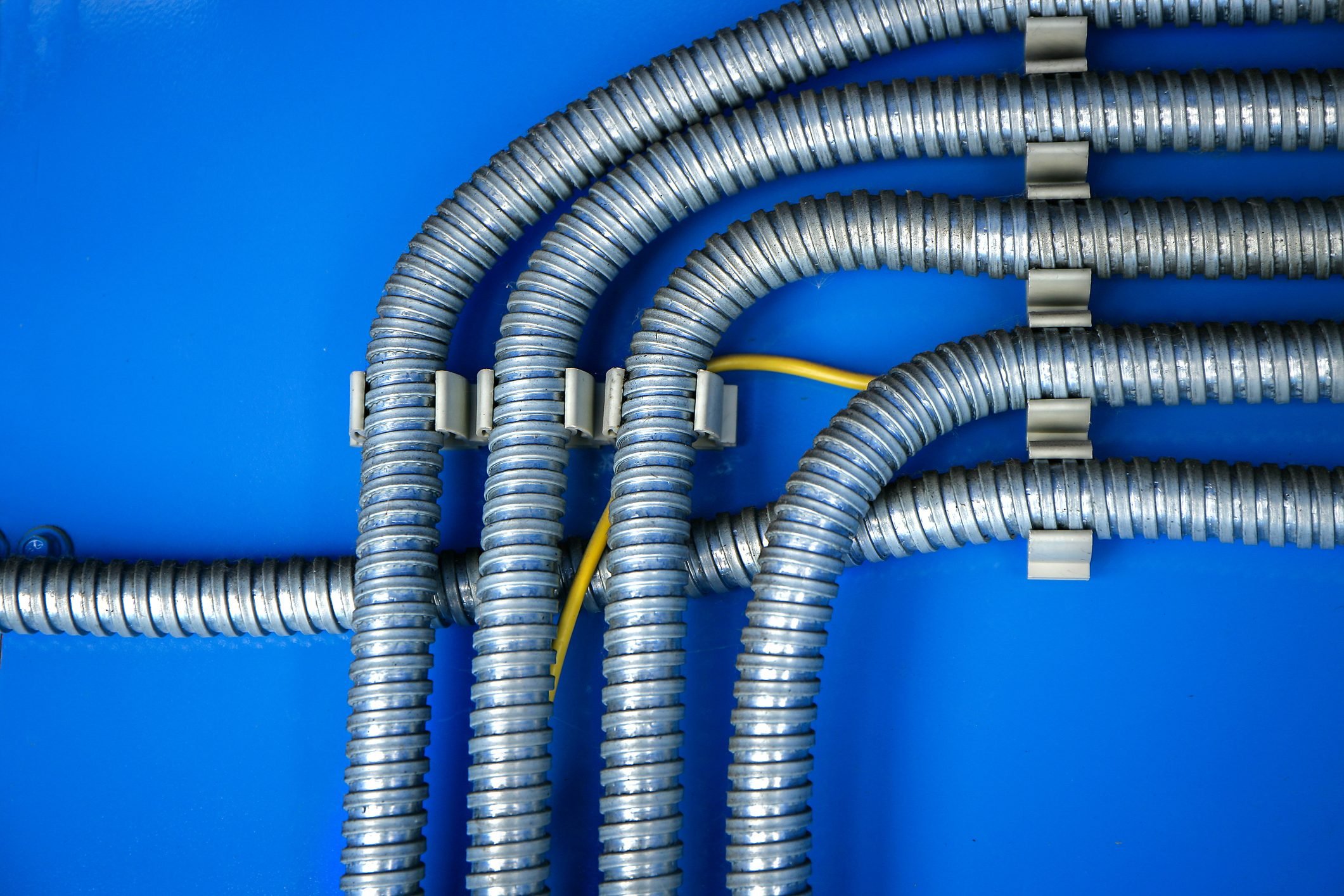

- Every type of conduit, tubing or raceway has its own rules for securement and support. Conduit straps are inexpensive and come in a variety of styles. Generally, metal conduits need to be secured within 36 inches from an electrical box and at seven-to-10-foot intervals. PVC conduit needs to be secured more often every three to five feet depending on size. Flexible conduits need to be secured 12 inches from boxes and every 4-1/2-feet thereafter. When in doubt, add more straps for a safe and professional-looking installation.

- Some metal conduit, tubing and raceway systems can be used as an equipment grounding conductor if the conduit system is complete from end to end, and all of the proper connectors, fittings and boxes have been used. To be safe, and for an extra couple of dollars, it’s best to just pull a green-insulated equipment grounding wire into the conduit along with the other hot and neutral wires.

Rigid Metal Conduit (RMC)

RMC is a threaded conduit that offers the most robust protection for wires and cables, like underground wiring. But it’s difficult to work with because it’s hard to cut, and cut ends need to be threaded (unless you use threadless connectors and couplings). It’s also heavy, hard to bend and expensive.

Flexible Metal Conduit (FMC)

FMC is made from helically wound, formed, interlocking metal tape. It’s handy for making connections to stationary appliances that may need to be moved for cleaning, repair or replacement, like an electric range, a dishwasher or an electric water heater.

It’s also handy as the final connection to a piece of equipment that might vibrate, like a large air compressor in your workshop. It can also be used for protecting wiring inside cabinets.

Liquidtight Flexible Metal Conduit (LFMC)

LFMC is basically just FMC with an outer liquid-tight, nonmetallic, sunlight-resistant jacket over the flexible metal core.

Rigid Polyvinyl Chloride Conduit (PVC)

PVC conduit is the nonmetallic cousin to RMC. However, PVC conduit is really easy to install. Just cut it to length and glue it together!

Schedule 40 PVC is commonly used for the installation of underground wiring to a detached garage or tool shed, or it can be used indoors like a garage or tool shed. The NEC requires heavy-duty Schedule 80 PVC on the side of a building where you transition from below ground to above ground as added protection from lawnmowers and weed whips.

The wall cross-section for Schedule 80 PVC is thicker, but the external diameter of Schedule 40 and Schedule 80 is identical, so all the PVC connectors and couplings are interchangeable.

Liquidtight Flexible Nonmetallic Conduit (LFNC)

Like rigid PVC conduit, LFNC is easy to work with. It’s similar to LFMC except it lacks a flexible metal core. It looks like a gray garden hose. Lots of connectors are available.

Electrical Metallic Tubing (EMT)

EMT is an unthreaded thin-wall raceway of circular cross-section. It’s easy to cut with no threading necessary. It’s easy to make 90-degree bends, offsets and saddles with a conduit bender, and it’s easy to install. Pre-bent factory elbows are also readily available, along with many connectors, couplings and fittings.

Electrical Nonmetallic Tubing (ENT)

ENT is a nonmetallic, pliable, corrugated raceway of circular cross-section. It’s basically a nonmetallic version of FMC.

Surface Raceways (Metal and Nonmetallic)

Surface raceways are easy to install. They’re typically used when you need to extend some wiring for receptacles and light switches but don’t want to remove the wall covering material, be it gypsum board or paneling.

Surface raceways are more aesthetic than conduit or tubing and can be painted to match the decor. Metal or nonmetallic raceway systems are available.