How to Safely Jack Up a Truck

Updated: May 12, 2023

Follow these steps to get your truck up on jacks and ready to work on.

Advanced

Introduction

Learning to properly jack up and support your truck before you start doing your own oil changes or making repairs is vital to your safety. Different vehicles have different support points; start by checking the owner's manual.Tools Required

- 4 Jack Stands

- Car jack

Project step-by-step (6)

Basic Car Jack Safety

You can save quite a few bucks by knowing how to jack up your truck and doing your own repairs and maintenance. But if you want to live long enough to spend all the money you save, you owe it to yourself and your loved ones to study up on jack safety.

Find a Flat Surface

- Start by parking your truck on a flat concrete surface.

- Pro Tip: Place jack stands on plywood support plates when you’re working on an asphalt surface.

- Trucks and most SUVs have steel frames that support the entire vehicle. Nearly all cars, on the other hand, are of “unibody” construction, meaning they don’t have a frame. So each type of vehicle requires different points of support for jack and jack stand placement.

Consult a Manual First

To learn how to jack up your truck properly, consult a repair manual to locate the recommended lift points and support locations for your specific vehicle. Repair manuals are usually available at auto parts stores or online.

- Before you begin the jacking process, engage the parking brake and chock the rear wheels to prevent unwanted movement.

- You’ll want to start jacking from the front of the vehicle. The front end of four-wheel-drive trucks can be raised by placing the jack under the differential.

- Pro tip: For two-wheel-drive trucks, place the jack beneath the jacking pad under the engine.

Pumping Up the Jack

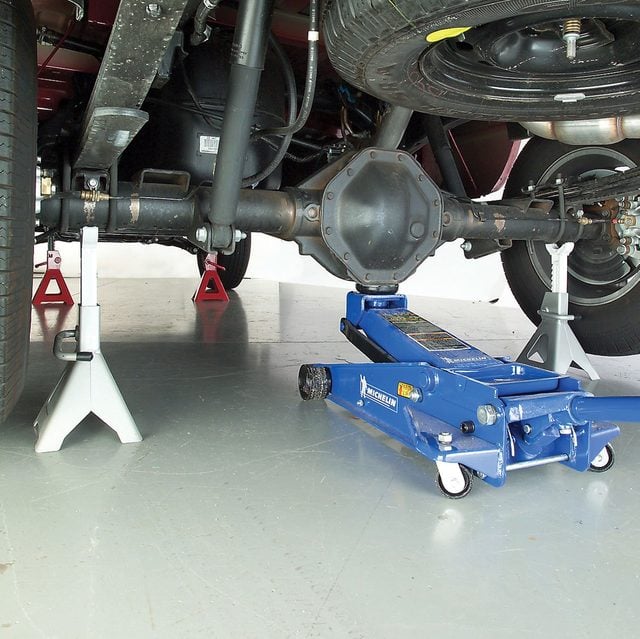

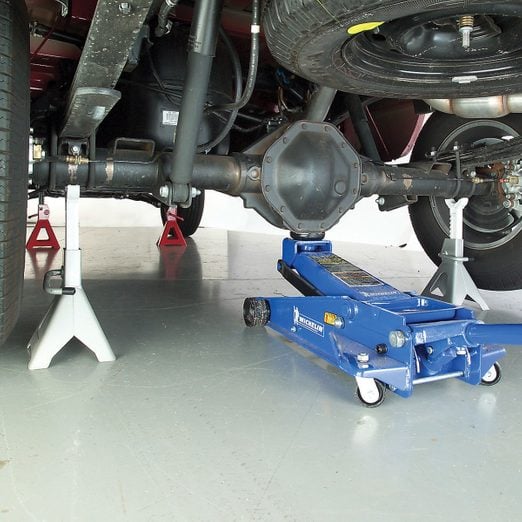

- Place the jack so the cross member or differential lines up with the recessed area of the jack saddle.

- Slowly pump the jack handle until the front wheels leave the ground, then stop jacking and double-check the jack placement.

- Look at the front of the vehicle to make sure it’s not leaning to one side. If it is, lower and recenter the jack. Otherwise, continue pumping until the vehicle reaches the desired height.

Place the Jack Stands

- Support the front of a truck by placing the jack stands directly under the frame. Support the rear of the truck with a jack stand under each axle.

- Turn the handle very slowly until the vehicle starts easing down. A quick-release will result in a sudden catastrophic drop.

- Lower the truck until it almost touches the saddle of the jack stand. Then make final alignment adjustments before lowering the full weight onto the stand.

- Remove the floor jack and bring it to the rear of the vehicle.

- Locate the recommended rear lift point and repeat the jacking procedure at the rear of the vehicle. Place the two rear jack stands in proper support locations and lower the rear onto those stands.

Test the Support Points

- With the vehicle up on all four jack stands, gently shake the vehicle side to side and up and down. This ensures that the vehicle is sitting squarely on the jack stands and that the jack stand saddles have full contact with the support points.

- If the vehicle wobbles, stop immediately and reposition the problem jack stand before crawling under the vehicle.

- Pro Tip: If you plan to remove your tires, loosen the lug nuts slightly while the truck is still on the ground. That’ll keep the wheels from spinning while you turn the lug wrench once the truck is raised.