Shape it, cut it, decorate it, dado it. All with an everyday wood router.

An hour or less

Beginner

$101–250

Introduction

A wood router does more than cut fancy edges. It'll also cut flawless dadoes and rabbets and perfect patterns. Our basics here show you how to set up and execute these cuts with outstanding results.

Tools Required

- Clamps

- Drill/driver - cordless

- Router

Project step-by-step (8)

Edge Routing

The two keys to routing clean edges are using a sharp bit and running the router in a counterclockwise direction around the top of the workpiece. That way, the bit pushes the router toward you rather than pulling it away, so it’s easier to control and safer.

But the counterclockwise wood routing technique doesn’t always work perfectly. There’s a tendency for the wood to chip out at the corners. Solve the problem by “climb-cutting” (or cutting clockwise) for a couple of inches on the end grain at the “northeast” and “southwest” corners of the board. Then start anywhere on the workpiece and run the wood router around the wood counterclockwise. Note, though, that if you’re edge-routing the inside of something, like a picture frame, rout in a clockwise direction.

Always test your cuts on a similar scrap of wood to confirm proper cutting depth. If the wood burns, sneak up on the final cut depth by making three consecutively deeper cuts. Removing a little wood at a time will prevent burns.

- Pro Tip: Sand wood edges smooth before routing with edge trimming bits. Any flaw that the bearing encounters in the edges will be transferred to the new profile.

Make Deep Cuts in Stages to Prevent Burning

Making deep cuts in a single pass runs the risk of chipping the board and marring the finished profile. Make deep cuts in several passes, cutting deeper each time. Some wood species tend to chip more than others, so run a test on a scrap board of the same species.

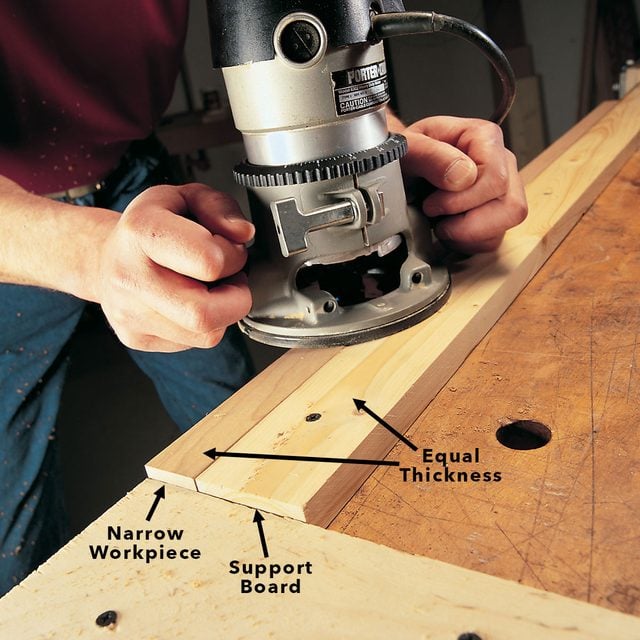

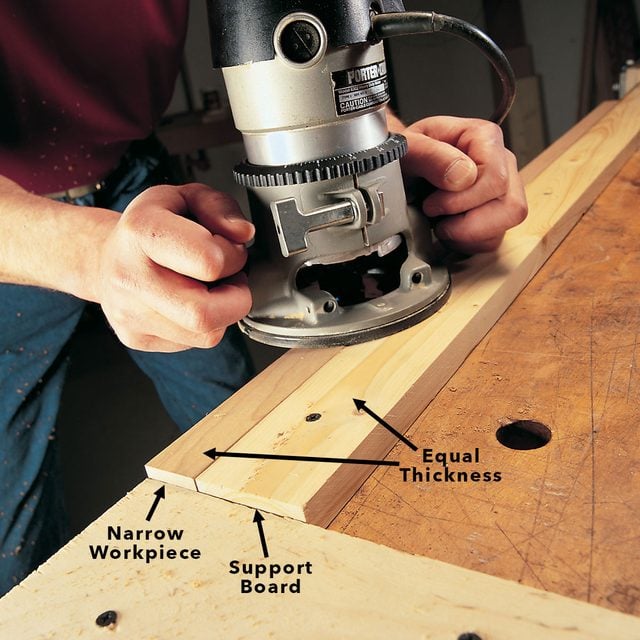

Edge-Routing Narrow Stock

Routing a smooth, clean edge profile on narrow pieces of wood is tricky. Clamps get in the way of the router and it’s hard to keep the base from rocking on the narrow surface. Solve both problems by screwing to the workbench a support board that’s the same thickness as the workpiece. Screw a stop to the bench at the end of the board to keep it from slipping. That gives the router a wider surface to rest on, eliminating any rocking and forces the workpiece against the support board and the stop, so it doesn’t need clamps.

Use a Jig to Cut Dadoes

Dadoes (or grooves) are the cleanest, strongest way to invisibly support shelves on the sides of cabinets or bookcases. Once you try this jig, dadoes will become standard in your shelf-building repertoire. The easy way to make dadoes is with a wood router, a straight bit and a simple homemade jig. The jig is nothing more than a T-square made from a straight 2-ft. length of 1×2 screwed to a straight length of 1×6.

- Make the 1×6 a few inches longer than the wood you’re routing plus an extra 1-1/2 in. for joining the 1×2.

- Screw the jig together with 1-1/2 in. wood screws, using a carpenter’s square to keep the jig perfectly square during assembly.

- Buy a bit that matches the desired dado width so you can make the cut in one pass.

- Clamp the jig (front and back) on a test piece of wood, then set the straight bit 1/4 in. deep and make a pass through the right side of the “T” part of the jig and into the wood.

- Check the new dado with a square to make sure the jig is square and you’re ready for the real thing.

- Plan and mark the dado locations on the workpiece, then line up the jig’s groove with your layout marks, clamp the jig to the wood and dado away. Learn how to DIY end grain router jig.

- Cut only on the right side of the jig and push the router away from you; the turning direction of the wood router bit will pull the router base against the jig.

- If you rout on the left side of the jig, the router will tend to wander away from the jig and you’ll wind up with a run-amuck dado.

How to Cut a Rabbet Joint with a Table Saw

Rabbets and Rabbets Bits

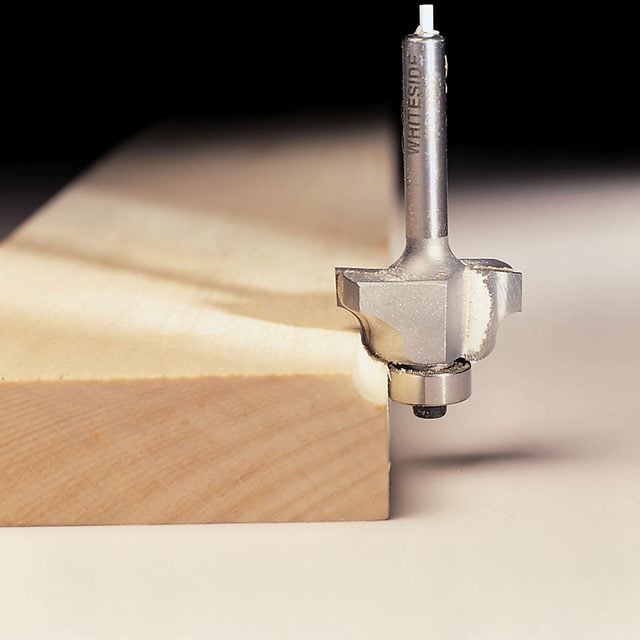

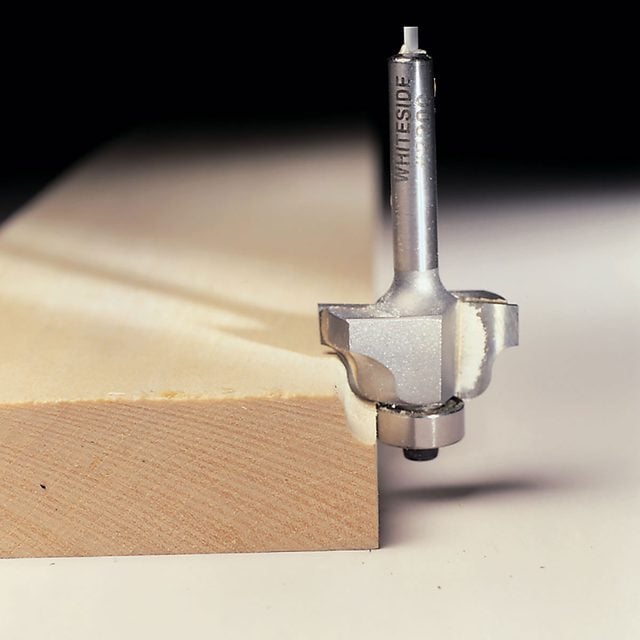

Rabbets are grooves that are cut into the back edge of cabinet or bookcase sides for insetting plywood backs. Rabbets conceal ugly plywood edges for a cleaner look. The key to good rabbets is to use special rabbet bits that automatically cut the perfect width. They’re available at home centers and woodworking stores individually or in kits that allow you to swap pilot bearings to adjust the rabbet width with the same cutting bit.

- To use a rabbet bit, first select the pilot bearing that will cut a groove the same thickness as the plywood back. That way the plywood back will be flush with the back of the cabinet.

- Then adjust the depth of the router so the bit will cut about 1/2 in. deep, leaving plenty of surface for gluing and fastening. Cut counterclockwise.

- Cut rabbets in one pass, using the proper pilot bearing. Various bearing sizes allow you to adjust the width of the rabbet cut.

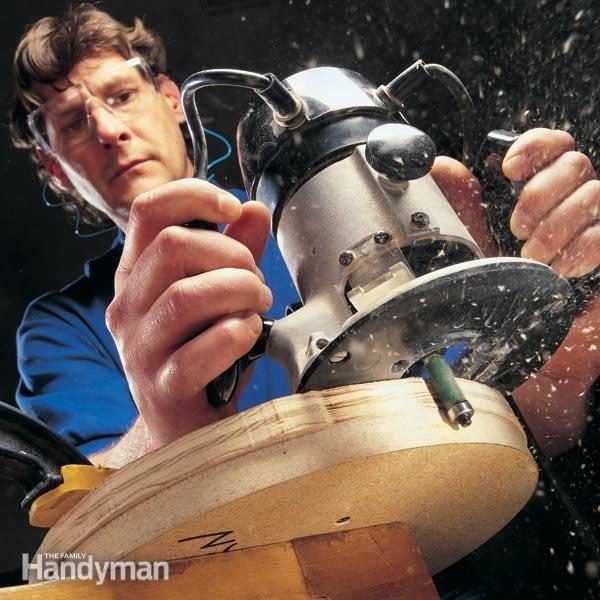

Cut Perfect Patterns

Patterns allow you to make multiple copies of nearly any shape with a router and a bottom-bearing flush trim router bit. This technique is great for various router projects. The key is a perfect pattern with smooth edges. Use 1/2- or 3/4-in. plywood, particleboard or fiberboard for the pattern. The thinner material won’t give enough depth for the pilot bearing to ride on.

- After you finish cutting the pattern and smoothing its edges, trace the shape onto the stock you’re planning to cut.

- Cut out the shape with a band saw, jigsaw or scroll saw about 1/8 to 1/4 in. outside the line. Don’t worry about getting a smooth, even cut; the flush trim bit will clean up the imperfections.

- Attach the pattern to the stock with a few drywall screws, but be careful to select shank lengths that won’t poke through the “show side” of the workpiece.

- If both sides will show, use thin brads and carefully pry the pieces apart after routing and patch the holes. Then it’s just a matter of flipping over the assembly, clamping, and running the flush trim bit around the pattern to create the duplicates.

- Pro Tip: You may not be able to finish the edge in one continuous motion. Depending on the shape, the clamps may get in the way. You’ll probably have to stop, shift the piece, reclamp and resume routing to finish the edge.

Router Bit Savvy

Wood routers have router bits that come in two types, carbide-tipped and high-speed steel. Don’t waste your money on high-speed steel bits. They’re cheap, but they won’t hold an edge for long and they don’t have ball-bearing pilots, so you’re more likely to burn and tear the wood. Carbide bits cost about three times as much as high-speed steel ones, but they stay sharper at least 10 times longer.

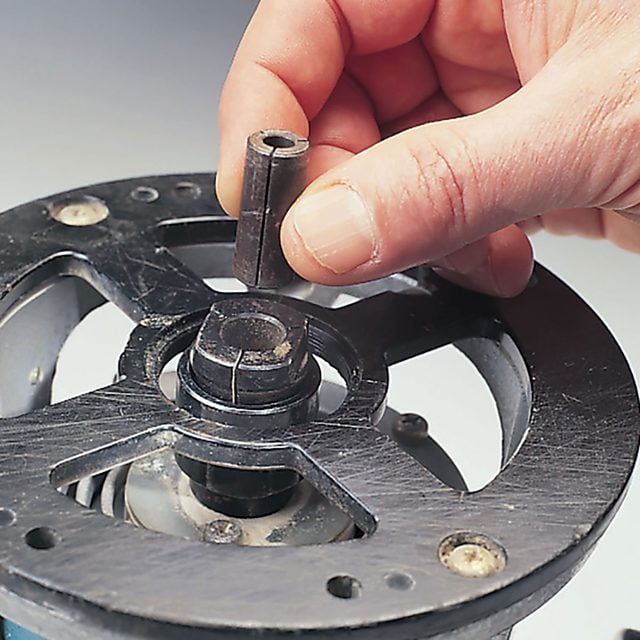

Router bit shanks come in two diameters, 1/4-in. and 1/2-in. Examine the collet (where the bit inserts) on your router to determine the bit shank size(s) it can handle. Some routers will only accept 1/4-in. shanks, while others come with substitute collets or collet-adapting sleeves so you can switch back and forth between shank sizes. Generally speaking, buy 1/2-in. shank bits if you can. With that size, there’s less deflection in the shank, which means less wobble and cleaner cuts.