Replacing broken wheel studs is not as hard as it looks.

1 hour

Intermediate

Around $60

Introduction

Tightening lug nuts without a torque wrench can be a recipe for disaster. If worse comes to worse and you break the wheel stud, here's how to replace it.

If you’re like everyone else, you’ve tightened the lug nuts on your car without using a torque wrench. You’re an “all the muscle you can put into it” kind of guy, and now you’re staring at a broken wheel stud.

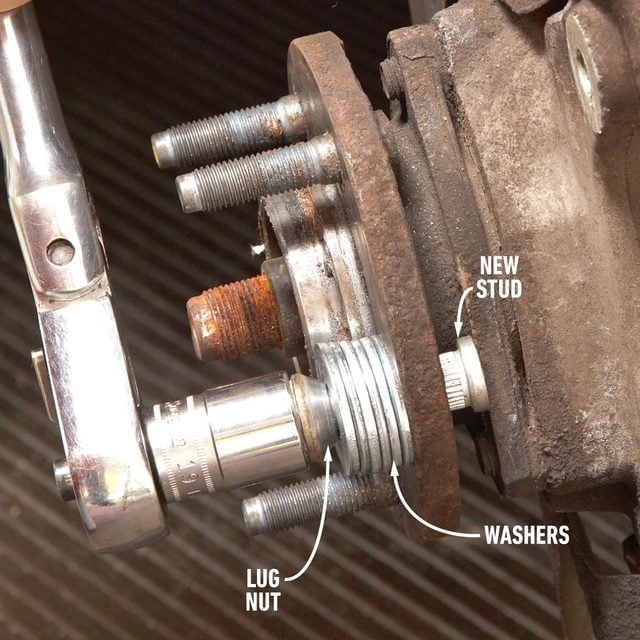

You can fix tire bolts yourself in about an hour for less than $60. You’ll need to buy a tie rod end remover or rent one from an auto parts store. Then buy a new stud and two new lug nuts (yes, two of them). Next, stop at the hardware store and get a handful of washers with a hole diameter slightly larger than the threaded portion of the stud.

Though a simple and straightforward task in most cases, it can also be frustrating and time consuming if the broken stud has rusted on after many years of harsh weather or neglect. There’s no shame in turning this over to a reliable mechanic in your area.

What is a Wheel Stud?

Wheel studs hold the tire in place. When changing a tire, you remove lug nuts from the wheel studs, allowing the wheel to come off.

Wheel studs, often called tire bolts, are threaded metal rods, typically made of steel, that protrude from the wheel hub, usually through the brakes. Their main purpose: Securing the wheel to the hub. Improperly tightened lug nuts, too loose or tight, can cause wheel studs to break, and your wheel to fly off when in motion. That could have grave consequences.

Regular inspection of wheel studs is important for vehicle safety and reliability.

Tools Required

- Socket/ratchet set

- Tie rod end remover

- Torque wrench

Materials Required

- 2 - Lug nuts

- Steel washers

- Wheel studs

Project step-by-step (2)

Broken Wheel Stud Replacement

How to remove a broken wheel stud

Don’t hammer out the broken stud. That’s the worst thing you can do! The hammer blows can wreck your wheel bearings, turning this into a much bigger repair bill. Instead, squeeze the broken stud out with the tie rod end remover. While you’re at it, find out the cost of replacing wheel bearings.

- Place the remover around the head of the broken wheel stud, behind the hub.

- Center the driving screw over the broken end of the stud and tighten it with a socket wrench until the stud pops out the back. The wheel stud end is staked (or compressed) into the hub, so getting it to budge is the tough part. Once it moves, the rest is easy.

- Rotate the hub until you find a deep recess so you can angle the stud into the hole. Then pull it through.

Installing a wheel stud

To install the new wheel stud:

- Place a bunch of washers over the new wheel stud and spin on the lug nut.

- Crank down on the lug nut to pull the staked portion of the new stud into the wheel hub.

- Stop tightening when the head of the wheel stud sits flush with the back of the hub. By this point, you’ve probably stretched the threads or damaged the bevel on the lug nut. So toss it, they’re cheap.

- Install the second lug nut (the one you didn’t toss) on the new stud — it’ll go on easier.

- Be sure to tighten your lug nuts with a torque wrench from now on so this doesn’t happen again.

Note: If you can’t fit the new stud into the hub, you may have to remove the brake dust shield. Drill out the rivets and replace them with stainless steel screws, nuts and thread-locking adhesive.