Professional techniques for coping perfect molding and trim joints.

An hour or less

Beginner

Varies

Introduction

The secret for a glove-tight fit for trim corners is a coped joint. This age-old carpenter's trick involves cutting the profile on the end of one molding and fitting it against another like pieces of a puzzle.

What is a Coped Corner?

Two walls are rarely a perfect 90-degree angle. So getting two miters to meet tight can be challenging, even if you’re a miter saw master. In a coped baseboard corner, one molding has a square cut on the end that butts against the adjacent wall. The other molding fits perfectly against the face of the first molding by cutting the end to follow the profile of the molding.

Tools Required

- Coping saw

- Flat file

- Miter saw

- Round file

Materials Required

- Baseboard trim

Watch How to Cope Joints for Wood Corner Trim

Project step-by-step (3)

Make a Miter Cut

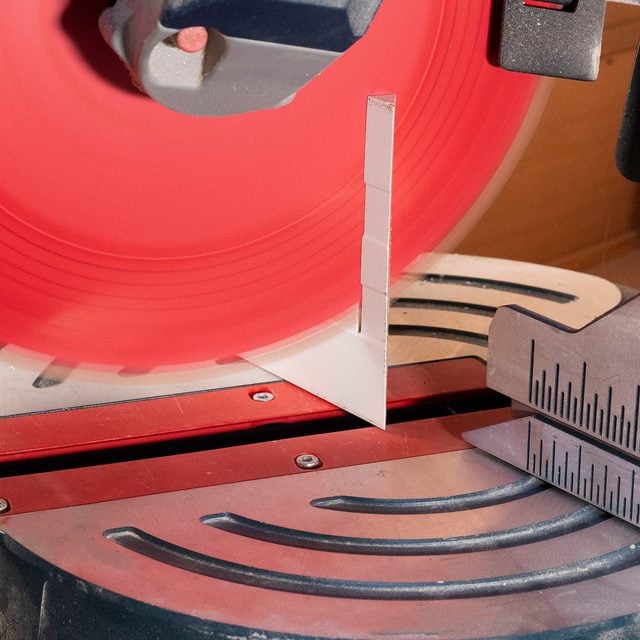

- Set your miter saw at 45 degrees to the left. Position the molding upright so the back is flat against the fence of your miter saw.

- Cut a 45-degree angle off the end of the baseboard. (See photo.)

- Set your saw at 22-1/2 degrees. Turn the molding upside down, cut straight down, and stop at the curvy part of the profile. (See photo.)

- Pro tip: Always cut the baseboard a couple of inches too long; you can cut it to the final length after the coping is done.

- If the fence on your miter saw isn’t tall enough, add a 1×4-in. board to hold the baseboard secure when cutting.

Cut the Cope

- First, make a few relief cuts at tight turns of the profile to allow waste to fall away and your saw to make turns more easily. (See photo.)

- Carefully saw along the profile created by the miter cut using a coping saw. (See photo.)

- Angle the coping saw about 30 degrees to remove more wood from the back of the molding.

- Pro tip: Coping cuts often create thin, pointy tips on the trim. Support those tips with your finger as you cut, file, or sand to prevent them from splintering off.

- Pro tip: Concentrate on staying just outside the line. You can always sand or file away extra material.

Fine-tune the Cope

- Clean up the coped cuts with a file or sandpaper. A round file works well for tight curves.

- Pro tip: Keep a scrap of the trim handy so you can check the fit as you fine-tune the cope. With complex profiles, you may have to fine-tune the fit several times before it fits properly.

Coping Tips

Start out straight up

The baseboard often tilts inward at the bottom because of the drywall’s tapered edge. And that makes coping tricky.

To avoid trouble, make sure the baseboard sits square to the floor. If it tilts, remove it and drive a screw into the framing near the floor. Leave the screw head slightly proud so it holds the baseboard away from the wall. Then check again with your square. You may have to turn the screw in or out a little to get the baseboard to stand straight up.

Brighter is better

With good lighting, you’ll get faster, better results. So take a minute to set up a work light or move your workstation near a window.

Clamp it down

Hold your work steady with a clamp or two. Your results will be much more precise.

Coping saw setup

If you’re using your grandpa’s coping saw — well, actually any coping saw — do three things:

- Replace the coping saw blade if it’s rusted or worn. Blades have 10 to 20 teeth per inch; use one with at least 15.

- Make sure the teeth point at the handle. Coping saws are designed to cut on the pull stroke (though some carpenters use them backward).

- Make sure the coping saw blade has proper tension. Adjust the tension by rotating the handle clockwise or counterclockwise.