Everything you ever wanted to know about dump trailers (And probably a couple things you didn’t).

What You Need To Know About Dump Trailers

What’s there to know about dump trailers? You fill them up, and then dump them out. Right? Well, not really. Whether you’re in the market for a used trailer, buying one off the lot, or ordering a custom build, there are a whole bunch of options for you to consider. The average dump trailers costs about $8,000 to $10,000. You don’t want to drive off with a trailer that’s not going to do the job, and you don’t want to spend a lot of extra money on features that will never get used.. To help us walk us through the basics, we met with Skylar and Derek at Midsota Manufacturing. They gave us some great advice on which of the dozens of trailer options you should consider.

-Josh Risberg

What size dump trailer do I need?

When purchasing a trailer, you need to check out the towing limits of the vehicle you plan on hauling it with. Also, make sure your receiver and ball mount match those same limits. They often don’t, surprisingly.

Choosing your trailer size will be based mostly upon the kind of work you plan on doing with it. You can get dump trailers from 8-ft. to 30-ft. in length. The most common size dump trailer is 14-ft. because it’s a good size for hauling a skid steer but still reasonably maneuverable.

Deckover

Upsides

Because the body and bed on a deckover trailer sits on top of the wheels instead of between them, the beds can be built wider. Also, loading pallets onto a deckover trailer that is equipped with side gates is much easier because the fenders don’t get in the way.

Downsides

It’s harder to throw or load debris (or whatever) over the sides of a deckover trailer because they sit higher. Also, loading a skid steer (or anything, really) into the back can be a little tough just because the ramps sit at a steeper angle. Plus, the extra height will make full loads more top heavy.

Totally tubular

When it comes to the frame of your trailer there are three different configurations to choose from: channel, I-beam, and tubular. Different manufactures use different types. Here are the pros and cons:

| Type of Frame | Pros | Cons |

| Channel

|

Less expensive | Not as strong |

| I-beam

|

Less expensive than tubular

Stronger than channel |

Not as strong as tubular |

|

Tubular

|

Strongest | Most expensive |

Keep in mind that there are also different widths of cross-members that you can choose from: 12-in., 16-in., or even 20-in. (16-in. being the standard). The 12-in. cross-members will add to the durability of the trailer’s bed, but will also add weight.

Finishes

Galvanizing a trailer is one way to go above and beyond a normal paint job. Galvanizing is a process where the trailer is submerged in rust resistant chemical bath. Total submersion ensures that the chemical coats the inside of the tube frames and gets into all the other nooks and crannies. Galvanizing is not cheap, but it will increase the life-span of a trailer and definitely increases resale value.

Some manufactures are experimenting with bed spray liners, which is really cool on the durability side of things. This will help especially on the front of these trailers, which typically take a huge beating

Lifting Mechanism

There are a hand-full of different lifting mechanisms to choose from. You can get a telescopic-style hydraulic lift (usually mounted on the center front of the box) that will lift the box all the way to its dumping angle with just one cylinder. Or you can go with a dual-piston style that uses two pistons under the trailer to push the trailer up to its dumping angle.

But the option that many, if not most, manufactures are going with these days is called the scissor lift. The “scissor lift” uses just one cylinder to push the trailer up to its dumping angle. This option costs less because it’s just one cylinder and works like a scissor to get maximum leverage when dumping the box. The scissor lift also spreads out the footprint so you have less of a chance of racking the box and frame if you have an uneven load.

If you have the option, be sure to choose gravity-down over power down. Some trailers engage the battery when lowering the dump box, which can cut your battery life in half. Gravity down will let gravity do all the work, saving your battery for when you really need it.

Side wall options

Wall heights are an important thing to consider when buying a trailer. Most trailers have a standard 24-in. wall height, but if that’s not enough you can order or even build your own extensions.

New trailers can be ordered with tall side walls, or you can buy removable extensions. Wall extensions can be ordered in solid metal or expanded metal lath. Lath allows you to still see into the trailer, and it weighs less.

You can also build your own side and front walls out of wood. Wood extensions are not as sturdy but they do have other advantages: They are inexpensive, and easily replaceable if or when they get dinged with a skid steer bucket.

How thick should the metal be?

When deciding on which trailer to buy you can’t forget about metal thickness. Some manufacturers build trailers with thicker metal than others. The metal on the bed of the trailer is always thicker than the sides because the bed takes more abuse. If your trailer will never see anything other than mulch you shouldn’t be too concerned about the bed thickness. But if you plan on filling your trailer with boulders and concrete rubble a bed with thicker metal is the way to go. Just remember that steel is heavy so the thicker the metal, the heavier the trailer. The heavier the trailer, the less weight it can accommodate.

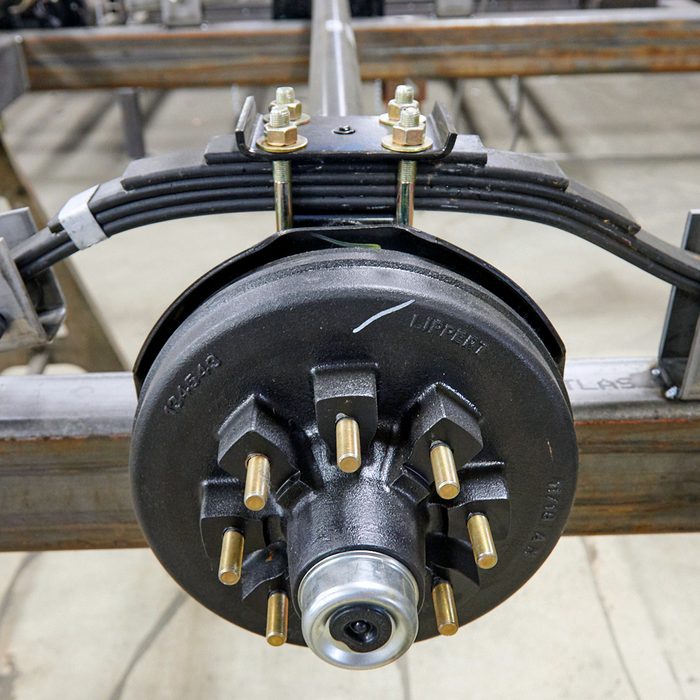

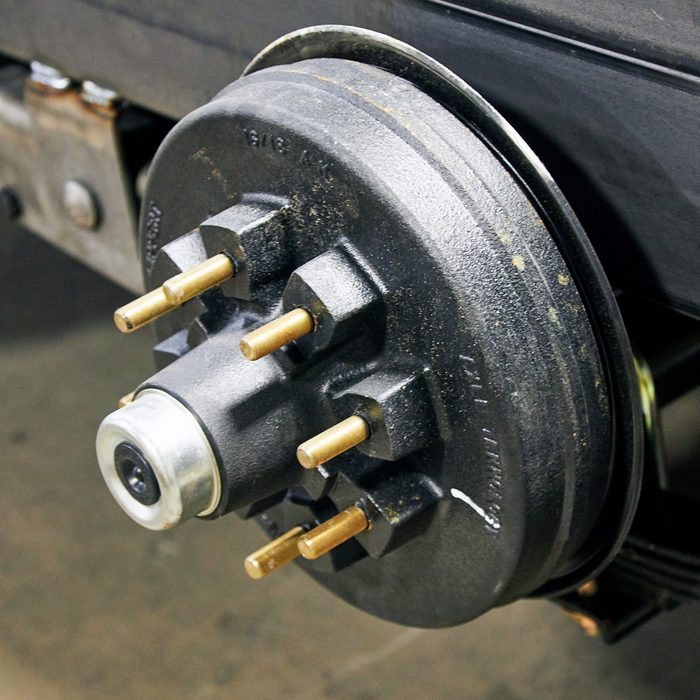

Axle Options

If you know that you are going to need to be able to handle more weight you can typically option to go to a larger axle. Usually larger axles require heavier duty wheels, thicker and more studs for the wheels, and larger brakes. The two main options are torsion axles and leaf spring axles.

Keep in mind that dump trailers are used, abused, and overloaded usually to their max limit. If you overload torsion axles and bend them it typically results in having to replace the whole axle, which can be an expensive fix. But if you are running leaf spring axles and you overload or damage them you can usually get away with replacing just the leaf springs. This ends up being a much lower cost than springing for an entirely new axle. Also, torsion axles aren’t typically made larger than around 12,000 lbs. per axle.

The main reasons that you would want to go with a torsion axle are that they require less maintenance over the life of the axle and are quieter because there are less moving parts. Overall, leaf spring axles are a better choice for dump trailers because they work together and perform really well on uneven ground.

Rear Gates

Here are the most common rear gate options:

| Type of gate | Pros | Cons |

| Single door | None that we can think of | Long length prevents pulling close to buildings

Dangerously Heavy |

| Barn door | Standard on many models

Easy to open and latch Can get pull up closer to buildings

|

None that we can think of |

| Truck bed | Can haul longer material | Not all manufacturers have them

Cost |

| Spreader | Good for spreading dirt and gravel |

Mechanisms can rust shut if not used often |

| Mesh | Weighs less

Wind can blow through Can see through

|

Small debris and rubble will pass through

Cost |

| Built-in ramps | Loading equipment is fast and easy | Not all manufactures have them

Cost |

| Hydraulic with Built-in ramps | Loading equipment is fast and super easy | Only a few manufactures have them

Cost |

Side gates

Without side gates, pallets need to be loaded into the back and pushed in to one another, and unloading them is even more difficult. Side gates make loading and unloading pallets a breeze and allow loads to be spaced evenly in the bed. Side gates also create easy access for tying down heavy equipment and machinery.

Ramps

Most ramps are stored underneath the bed near the back of the trailer, but there are companies hanging them on the side of the box. Ramps are heavy and the ones stored underneath are typically easier to wrangle into place. There are also ramps available that are built right into the tailgate which, if you plan on loading your dump with equipment on a regular basis, could be a good option . Want to get really fancy? Spring for a hydraulic assisted ramp/tailgate that can be lowered into position with just the pull of a lever.

Wheel options

Just because it works hard doesn’t mean it can’t look good. These aluminum wheels look great and they won’t rust. But keep in mind that some aluminum wheels are limited in the weight they can handle. Monstrously heavy rigs may only have the option of solid steel wheels, which can support a much heavier load.

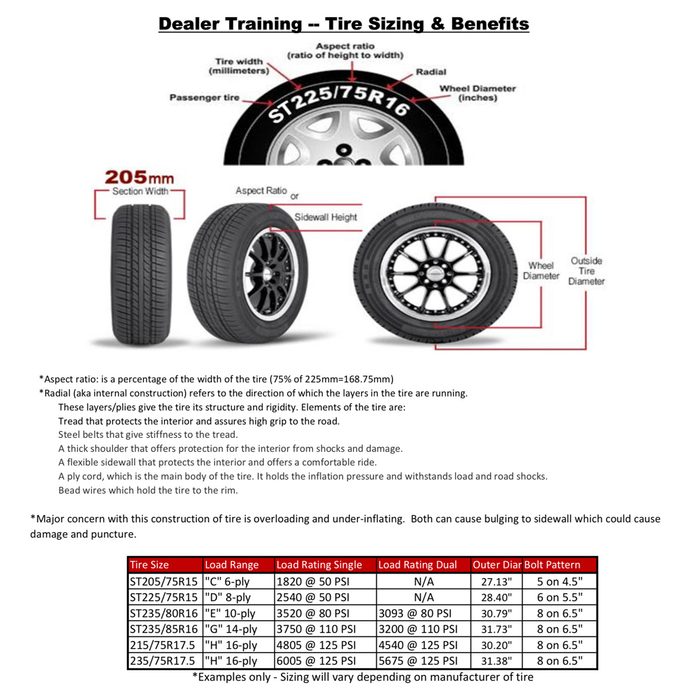

Tires

Tires need to be sized for your trailer. Be especially aware of this when shopping for a used trailer. Undersized tires are a safety hazard. There are a lot of things you can save money on when buying your trailer, but you should never skimp on your tires.

Spare tire holder

The most common location for a spare tire is the side or front of the box. Some manufacturers hide the spare under the bed, but this might not be the best option for those of you who live in a state where they use road salt to combat the harsh winters.

What’s to know about brakes?

Brakes are your best friends when hauling 20,000 pounds down the highway. Brakes are usually sized with the axle so there isn’t always an option for an upgrade. Some manufacturers do offer disc brake upgrades.

Most modern drum brakes have auto-adjustment systems that automatically adjust the brakes tension, which means no more climbing under your trailer in the snow, rain or hot days to adjust the tension.

The majority of brakes are controlled electronically, but there are surge brakes out there as well. The type of brakes is an important feature to keep in mind when buying a trailer made in a different part of the country. Some states don’t allow surge brakes on trailers over a certain weight, so be sure that when you buy a trailer it is legal to drive in the state you will be operating in..

Charging options

The hydraulic pump that powers the lift rams is almost always powered by an on-board battery. And of course the battery needs to be charged on a regular basis. Here are your charging options:

- A 110 charging stations that need to be plugged into an outlet

- A charge received from the truck when connected though a 7-way plug

- A solar panel on the box, which is a newer option (quickly gaining popularity) that makes a lot of sense

Some trailer manufacturers are now mounting gas engines that make batteries unnecessary. This could actually be a long-term money saving option because batteries usually only last a couple of years (often less), and they can cost as much as $200. An engine would also be ideal when making a bunch of back-to-back dumps where there is not enough time for the charger to keep up.

Couplers

The two most common ways to hook up a heavy (non 5th wheel) trailer are either a ball mount or a pintle. Either way, an adjustable tongue is a great option because not all trucks are the same height. To haul a trailer safely it should ride close to level. Pulling a trailer out of balance is dangerous, is hard on the truck, and causes uneven wear on the tires.

Pneumatic versus manual jack

If you know you’re going to be hooking up and dropping a trailer all the time, you should consider purchasing a hydraulic jack. Sure, cranking a manual jack doesn’t take that much energy, but the hydraulic option is faster, and who doesn’t like watching stuff go up and down hydraulically?

Tool boxes

There are two types of toolboxes, steel and plastic. Plastic boxes are great because they don’t rust. Steel boxes look nice when they’re new, but they rust. Be sure to get some sort of storage on your trailer.

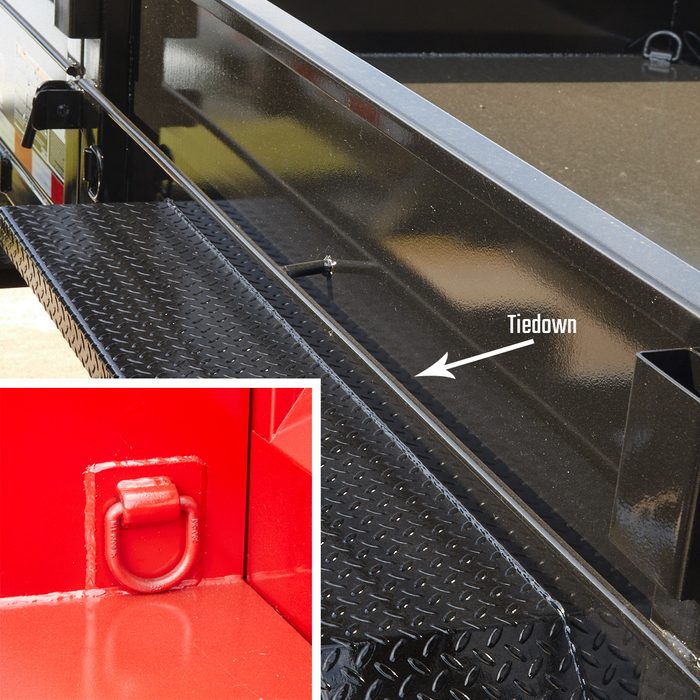

Tie downs

When hauling equipment, keeping your load secure is critical. Every trailer should have tie down anchors. Anchors on the side of the bed (instead of the floor) are nice because a broom or shovel won’t snag on them and material and debris won’t get hung up on them as easily when dumping.

A place on the outside of the trailer to hook straps and bungees is also a nice future for securing tarps.

Roll tarps

Covering a load is your duty to the other drivers on the road, and a roll tarp makes covering a load easy. Using a regular tarp only takes 10 minutes, but after a while those minutes add up.

Drop legs are a safety essential

Drop legs are an option that often gets overlooked. It’s not because they’re expensive; they aren’t. It’s because people don’t realize they need them until they load their first piece of heavy equipment and the tongue of the trailer pops up off the ground, taking the back of the truck with it. Or worse, the tongue comes loose and slams into the back of the truck causing thousands of dollars worth of damage. Drop legs keep the trailer nice and stable the entire time you’re parked.

Remote

A wired remote is standard on most trailer, but wireless remotes are new in the world of dump trailers. The great thing about wireless remotes is they let you keep an eye on the load while you drop it without having to run back and forth from your cab to the back of the trailer.

Mud flaps

Adding mud flaps to your trailer is a no-brainer. They protect the paint on the trailer and the other drivers on the road.

Chain holder

Having a spot to hook chains on your trailer is a nice option. Without a chain holder, the chains usually get laid over the tongue, which can chip the paint.

Fork holders

If you have forks, these fork holders are a must-have. Being able to carry forks on the side of the trailer frees up a lot of space in the bed.

Customization

If you have an idea for a customization it never hurts to ask. Many manufactures will fabricate custom accessories like built-in pockets to store shovels or rebar. There are also a ton of great products to help you get the most out of your trailer.

Warranty

A dump trailers is a relatively simple machine and is normally built like tank. But dump trailers are not cheap either, and if something does go wrong, you want the manufacturer to stand behind their product. Don’t assume a “5-year warranty” will cover everything for five years. Check to see what’s actually covered in those five years and if anything is prorated, and compare that to other trailer brands you’re considering.

Meet the experts

Skylar and Derek are sales reps from Midsota Manufacturing in Avon, MN. They have a combined ten years working with Midsota.