Tips for smoother, cleaner, more accurate cuts with your jigsaw.

How to Get The Most Out of Your Jigsaw

Protect the Work Surface

When making a cut, you need to firmly hold down the saw to keep the blade from chattering, and even then, it may vibrate a bit. The combination of downward force and vibration is tough on the work surface. Reduce marring by applying a layer or two of masking tape to the base of the jigsaw. Remove the tape when you're done so it doesn't leave a sticky residue on the base.

Cut Anything

The main mission of a jigsaw is to cut curves in wood, and it's easy to overlook its other abilities. Instead of slaving away with your hacksaw, grab your jigsaw to quickly cut steel, copper or any metal. You can also cut plastics and tougher stuff like ceramic tile and fiber cement siding. The key to success is to match the blade to the material.

Get the Right Saw For You

It's helpful to think of jigsaws in three categories: For $50 or less, you'll get a jigsaw that will do its job just fine, but you'll probably sacrifice features and power. For most DIYers, a saw in the $50 to $100 range is a good choice. It will have some special features and adequate power. Saws that cost over $100 will have large motors and all the best features.

Our favorite features are toolless blade change, toolless base plate bevel and oscillating control. Bonus features include an LED light, a blower to blow away dust, a larger base plate and a speed control dial.

If you'll be cutting a lot of material that's 1 in. or thicker, look for a saw with a higher amp rating (listed in the specifications). Smaller saws draw 5 amps or less; larger models go up to 7 amps. Larger motors also add a little “heft” to the saw, which helps cut vibration.

Some jigsaws have handles; some don't. Many pros like the no-handle “barrel-grip” style. They feel they have better control with their hands closer to the action. Folks with smaller hands often complain about the barrel being too large to grab.

Square the Blade

To get a square-edge cut, the blade has to be perfectly perpendicular to the base. So before you make a cut, make sure the blade isn't bent. If it is, just toss it or save it for jobs where a clean, square cut isn't important. With a straight, new blade in the saw, square it up. There's not a lot of surface area on the base, so a smaller square is easier to work with.

Cut With the Good Side Down

Most jigsaw blades cut on the upstroke, so chips and splinters occur mostly on the top of the wood. So if you value one side of a board more than the other, make sure you keep the good side face down, and mark and cut the less important side.

You can buy “reverse cut” or “down cut” blades that do cut on the down stroke. These blades are used when you want as little tear-out on the top surface as possible. Cutting out a sink hole in a laminate countertop is one common use for reverse-cut blades.

Oscillation Education

Most jigsaws offer oscillating action: While the blade moves up and down, it also lunges forward with each stroke. Typically, you can turn off the oscillation or select from three levels of oscillation. The higher the setting, the faster you cut.

But faster isn't always better. More oscillation means rougher, less accurate cuts. So turn the oscillation way down or off when you need clean or precise cuts or when you're working with delicate materials like veneers. Turn the oscillating feature off when you're cutting metal. Practice on a scrap to find the best setting for the material.

Make a Metal Sandwich

Jigsaws are great at cutting sheet metal, but it's difficult to clamp the material down so the saw blade doesn't just rattle the material up and down instead of cutting through it. One way to solve this problem is to sandwich the metal between two sheets of 1/4-in. plywood. Once the plywood is clamped down, the metal has nowhere to go, so you get a fast, easy, clean cut. You don't have to spend a bunch of money on plywood either; inexpensive 1/4-in. underlayment works fine.

Make Relief Cuts for Sharp Turns

There's a limit on how sharp a curve a jigsaw can cut, and that depends on the blade—the narrower the blade, the sharper the turns it can make. If you try to force the blade into a turn tighter than it's capable of, you'll either veer off your line or break the blade.

If you're not sure about a particular shape, mark it out on a scrap and practice on that. If you have a curve you know is too tight, make relief cuts. The sharper the curve, the more relief cuts you'll need. And be sure you don't cut past your line. Play it safe and leave at least a blade's width of material between the relief cut and your pencil mark.

Drill Starter Holes

If you need to cut out a hole in the center of the work surface—like a hole for a heat register in a sheet of bead board wainscoting—drill a hole slightly bigger than your jigsaw blade in two opposite corners. That way, you can make four neat cuts starting from the two holes.

A Blade for Every Occasion

There are a couple of basic things to know about blades: The larger the teeth, the more aggressive and rougher the cut. And the narrower the blade, the tighter the turns it can make. Narrow, double-sided blades are especially well suited for sharp turns because the teeth on the back side widen the kerf as you turn.

Match the type of blade with the material you're cutting—don't use a wood blade to cut metal. Most manufacturers have taken the guesswork out of blade selection—the description of the blade and what it does is usually written on the blade itself. Buy a combo pack and you'll be ready for most jobs. A 15-pack of quality blades costs less than $20, and you'll avoid making a special trip to the store.

There are also specialty blades designed for very specific jobs: blades for cutting tile and fiber cement, and flush-cut blades that extend the cut right up to the front of the base. Specialty blades are usually sold individually and can cost more than $10 each.

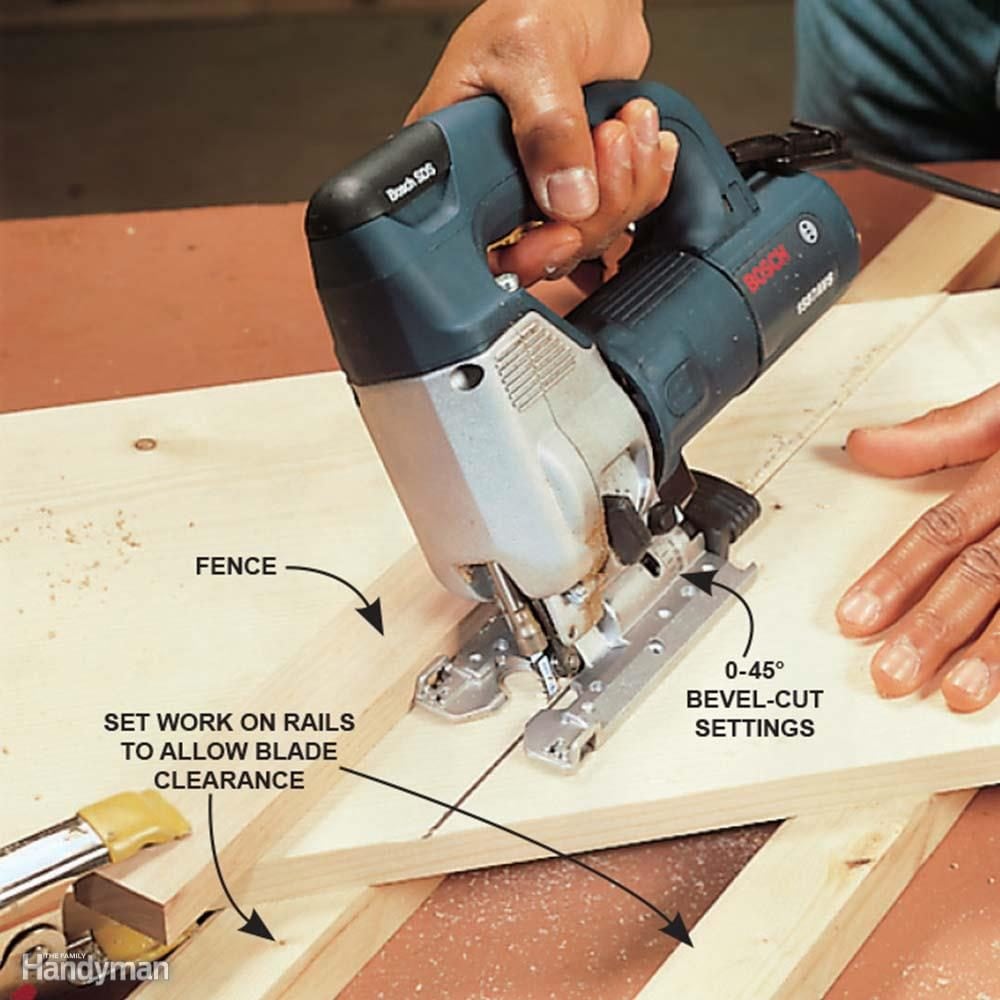

Use a Fence for Perfectly Straight Cuts

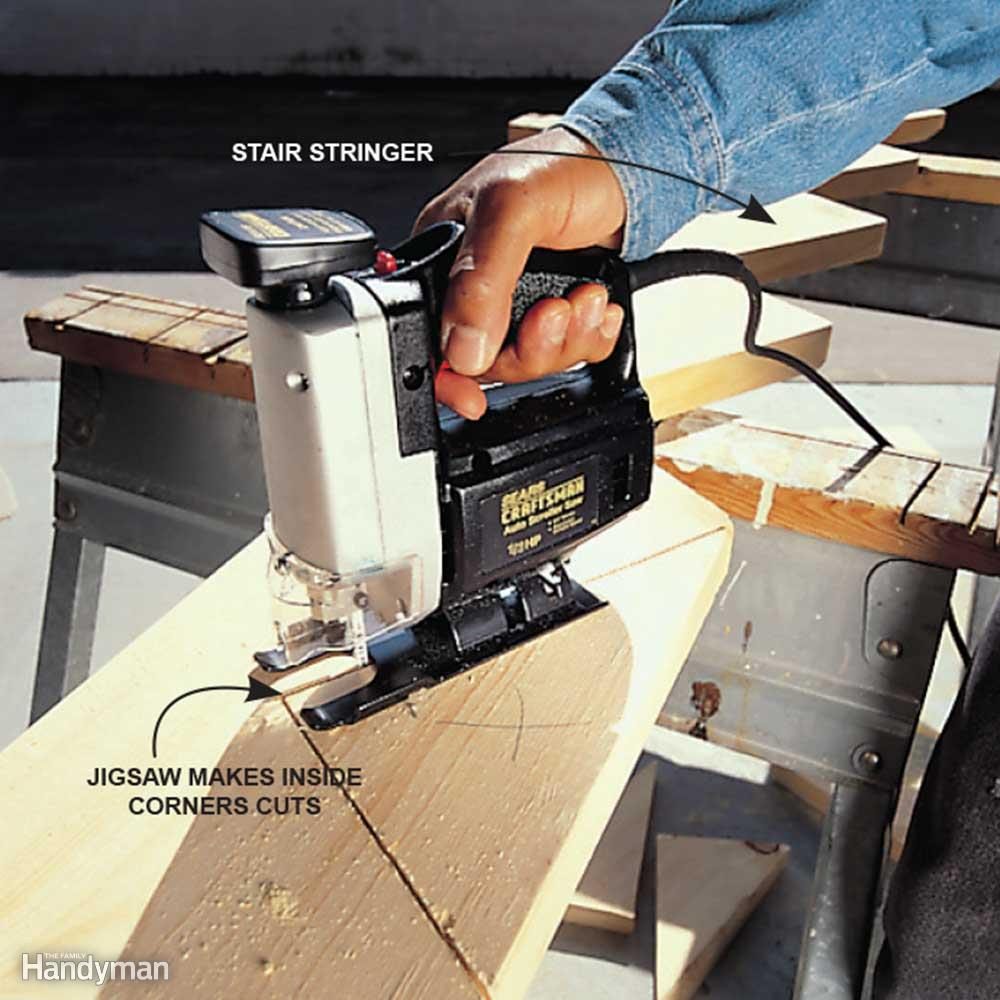

Finish Cuts Made With a Circular Saw

A jigsaw can precisely complete cuts begun with a circular saw in stair stringers, wood flooring and sheet materials. To avoid bumps in your final stair stringer, hold the jigsaw blade tight to the inside of the stringer cutting line.

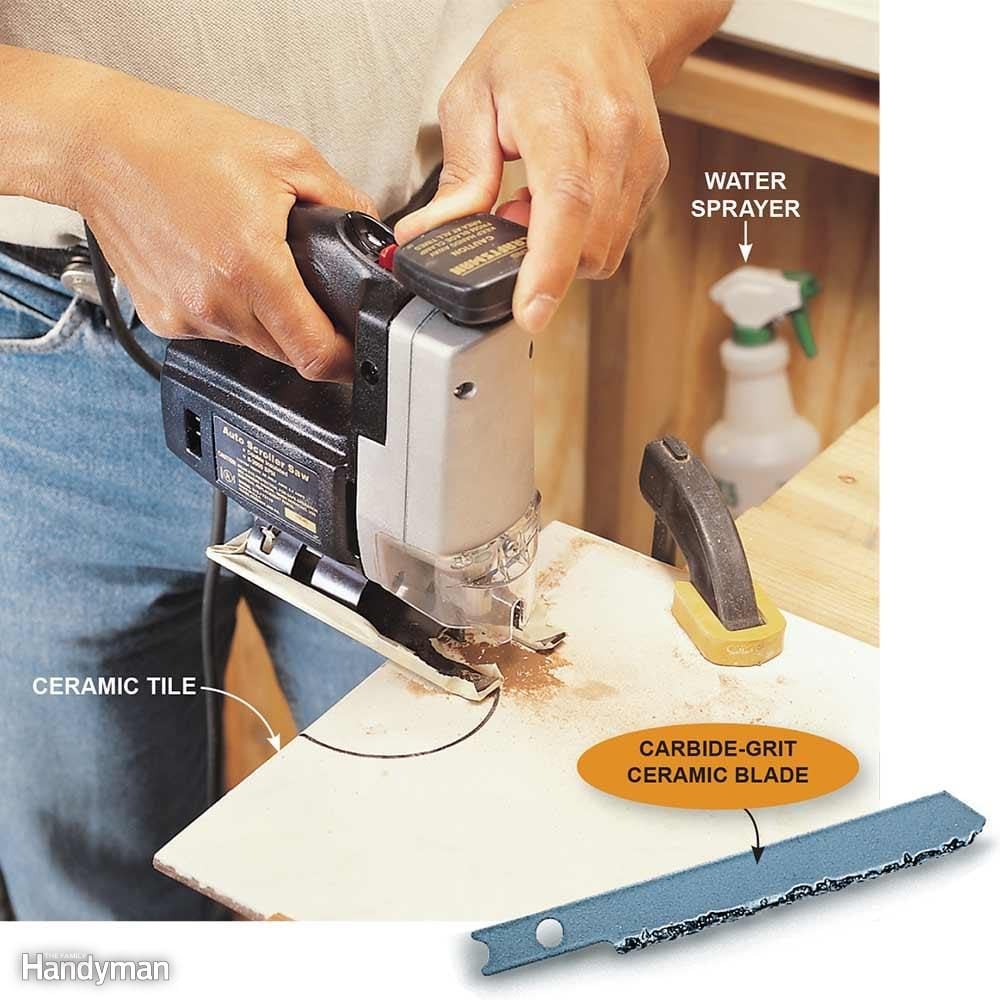

Cut Slowly When Working With Tile

Use a carbide-grit abrasive blade to make curved cuts in ceramic wall tile that's up to 1/4 in. thick. Use a diamond blade for harder types of tile and natural stone. Speed the work and reduce tile breakage by clamping the tile and using a light mist of water to lubricate the saw cut. This is slow work that demands patience, blade changes and relief cuts to open the tightest turns.