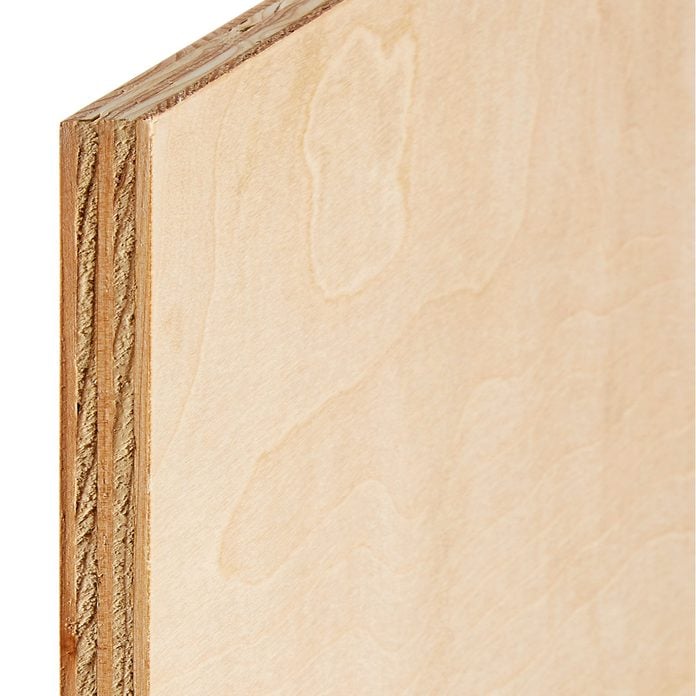

Veneer Core

Veneer core is made up of many layers of hardwood bonded together. The layers are assembled with alternating grain direction, called cross banding. This makes a strong, rigid, lightweight sheet with excellent screw holding capability. Because of these qualities, veneer core is my first choice in most cases.

MDF Core

Medium density fiberboard (MDF) core has a few advantages over veneer core. The thickness is more consistent, and MDF gives a smooth, even surface for the face veneer. It’s also more stable and typically flatter.

However, MDF core isn’t as strong as veneer core. It doesn’t hold fasteners as well and it’s heavy. But if I’m making one-piece doors, I’ll choose MDF core every time because of its flatness and stability.

We take the mystery out of the plywood grading system and show you what you will get in each grade. The higher the grade, the better quality you should expect.

Particleboard Core

Particleboard core is the least expensive option. Like MDF core, it’s flat and stable with consistent thickness. But particleboard core options are worse in the screw holding category. Also, it’s a special-order product, at least from my lumber yard, whereas MDF core is readily available.

Combination Core

Combination core weds the best attributes of MDF core and veneer core. The center cores are cross banded hardwood, providing strength, light weight and screw-holding capability. The outer cores are MDF, giving a flat, uniform surface for the face veneers.

However, combination core is a compromise. It lacks the screw-holding capability and rigidity of veneer core, or the flatness and stability of MDF core.

The Family Handyman DIY expert, Spike Carlsen, will show you how to cut construction grade plywood and finish grade plywood with a circular saw.

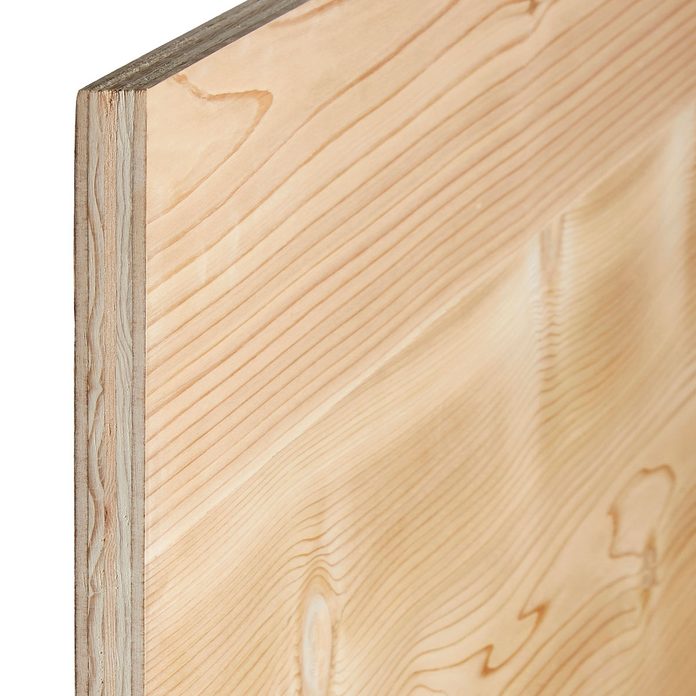

Lumber Core

Lumber core consists of edge-glued strips of wood, usually basswood. On both sides of the core there’s a cross banded veneer, then the face veneer. Like veneer core, it has excellent screw holding capability, strength and rigidity. But it’s considerably more expensive and harder to find than veneer core, so I almost never use it. However, it’s a good choice for long shelves.

Baltic Birch and Appleply

Baltic Birch and Appleply are top-notch veneer core plywoods, which you’ll only find at a lumber yard. Their 1/16-in.-thick core options veneer offer better stability than typical plywood with 1/8-in.-thick core veneers. The raw edge is attractive when finished and often used as a design element.

Baltic birch or ApplePly is my first choice for drawers and shop jigs. ApplePly is available in thicknesses from 1/4-in. to 1-1/2-in., and in many face veneer species.