In the workshop, garage, basement or shed, having wheels on your tools and equipment means you can easily move them out of your way to create more space.

Top Tips for Ultimate Workshop Flexibility With Tool Stands on Wheel

Use Wheelbarrow Wisdom

Combine a wheel and a lever and what do you get? A wheelbarrow—one of the most underrated inventions of all time. It’s easy to move, but when you come to a stop and lower the handles, it doesn’t budge.

Here’s how to apply wheelbarrow logic to shop tools. Mount a pair of large wheels on one side of the unit you want to move, then add removable handles.

Better yet, mount the wheels on the side of the unit and about 1/16 in. above the floor. When you tilt the unit by lifting up the handles, the wheels will touch the floor and you’ll be ready to roll. When you lower the handles, the unit will stay put, sitting solidly on all four corners.

The cart shown here has two 4-in. fixed wheels fastened to one side. The handles are made from PVC pipe and hardwood. Cut off the corners of the wood so they slip inside the pipe. Nest the PVC in boards cut with a V-groove and mount the pipe securely to the cart.

Portable Shelves

There’s always something in a workshop—like a stack of plywood—that you don’t need access to very often but you can’t easily store. Here’s a clever solution: Park a set of rolling shelves in front of it. When you need to get at the item, just roll the shelves out of the way. Some types of lightweight shelving come with optional casters; they just screw into the ends of the uprights. For heavier-duty shelving, like the shelves shown here, the most practical way to add casters is to mount them to a 3/4-in. plywood platform using carriage bolts. The platform also serves as the bottom shelf.

Choose Double-Lock Casters

Swiveling casters often come with built-in locks. No surprise there, but did you know that there are two different kinds of locks?

A standard lock prevents the wheel from turning but doesn’t stop the caster from rotating around its plate or stem. A cart or machine with these casters won’t roll away when locked, but it will jiggle when pushed. If you put them on a cabinet supporting a tool, a workbench or anything else that has to solidly lock down, you’ll be sorely disappointed. A double lock totally freezes the caster. The wheel won’t turn and the caster won’t rotate.

Choose Large Casters

Small casters may be inexpensive, but they take a heavy toll on your back—and on your patience.

Equipped with too-small wheels, a cart or machine is hard to push: You may have to lunge at it just to get going. Once you’re up to speed, every little crack or crevice in your floor will stop you dead in your tracks. If you bump up against a screw or nail that rolled off your bench or one of the small chunks of wood that undoubtedly litter your shop’s floor, you have to remove the offender or change direction. Talk about annoying!

For moving heavy loads or maneuvering over an uneven floor, go big. The problems mentioned above won’t go away, but they will be minimized. Use casters that are at least 2 1/2 in. in diameter. Casters up to 4 in. in diameter are best for really heavy stuff. The larger the caster, the less muscle power you’ll need to get rolling and keep rolling.

How to Arrange Casters

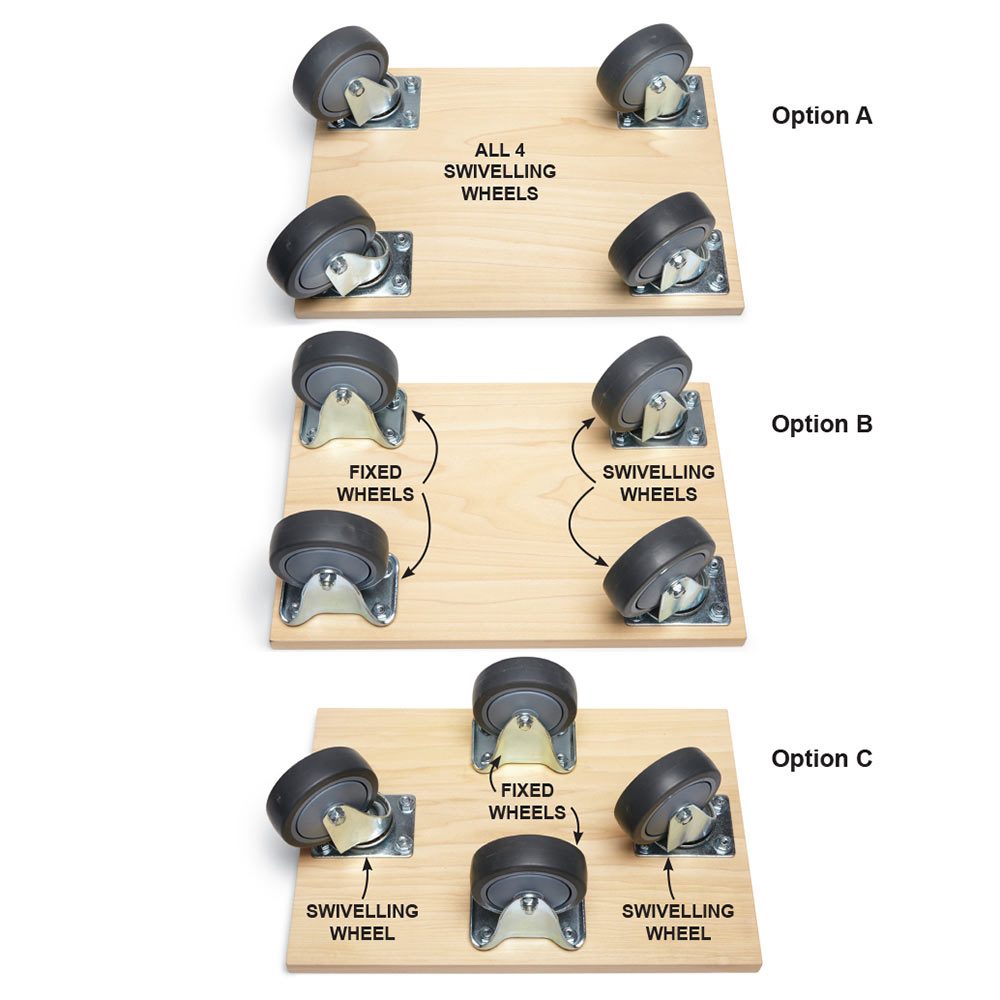

When most people put a cart or cabinet on wheels, they buy four swiveling casters and put one at each corner (Option A). Two other configurations are also worth considering.

You could substitute two fixed casters for two that swivel (Option B). Alternatively, you could move these casters to the center of each side of your unit (Option C).

What’s with all these options? Well, the choice comes down to whether you want your unit to be easy to maneuver into a tight space or easy to push in a straight line—or somewhere in between.

Option A, with swiveling wheels at all four corners, is best for parking your unit in a tight spot. If your shop is small and crowded, this is the way to go.

Option B, with fixed wheels at one end and swiveling at the other, is arranged just like your car or a grocery cart. A unit with this configuration tracks nicely and is easy to steer; it’s best for shops with plenty of room.

Option C, with wheels placed on centers rather than in the corners, is a good compromise between A and B. Carts used in railway stations and factories years ago were usually built this way. They could spin on a dime, but they also tracked well. This configuration does have a couple of disadvantages, however. First, the corners are tippy, so you must evenly distribute a load. Second, this arrangement doesn’t work on a cart with four legs. It’s really meant for a cart with a platform base.

Portable Scrap Bin

Here’s a low-rolling wood scrap bin that’ll capture all the cutoffs while you work on your next project. Bolt swivel casters to the base of a storage bin and it’ll scoot right where you need it. Sure, you can take extra time to beef up the casters-to-bin connection by bolting plywood on before attaching the casters, but it’s easier to bolt them right through the thicker, reinforced area of the bin’s bottom.

Big-Time Back Saver

If you can never find helpers when you need to move heavy objects, get yourself a hydraulic lift table on wheels. The table works great when you need to get large projects from your workbench down to the floor. You may be surprised at how handy this table is and how often you’ll use it. It can handle 500 lbs! Use it to help load stuff into the back of your truck and for moving heavy tools, like planers, from lower shelves up to your workbench. You can even use it to raise and lower projects for easier painting.

Our only complaint is that the table only reaches 29 in. (many workbenches are 34 in.). You’ll find these available online or at tool retailers.

Save Money on Casters

If you want some heavy-duty casters, buy a furniture dolly and remove the casters. You’ll probably get better casters for less money. Our local home center, for example, sells a furniture dolly with four 250-lb. casters for less than the cost of four individual casters rated for only 170 lbs.

We’d Love to Hear From You

Do you have a jobsite or tool tip that makes your work-life easier, safer, or just more fun? Why not share it with your construction comrades? Plus, you can show off your professional prowess to your family and friends.

Click the image below to send us your Pro Tips! Please include an image if you can. We will contact you if we run your submission on the site.