Disc brake calipers are crucial components within modern disc brake systems and are critical to safely and effectively slowing and stopping your car.

What Is a Brake Caliper (And How To Tell if Mine is Bad)?

Over my 50+ years as a master auto technician, vocational educator and vehicle owner, I learned the importance of a vehicle’s braking system—especially the calipers. So, I never wait for my brake pads to wear out before replacing them. I’ve seen how heat, road grime and debris, salt, rust, and corrosion have destroyed brake pads, rotors and calipers to the point that have resulted in nasty accidents. This is why visually checking calipers for potential problems during routine maintenance is essential. Always remember that brakes are your car’s most important safety system.

Here are tips from master automotive technicians to help you keep your disc brake calipers (and disc brake pads and rotors) healthier and make them last longer.

On This Page

What Is a Brake Caliper?

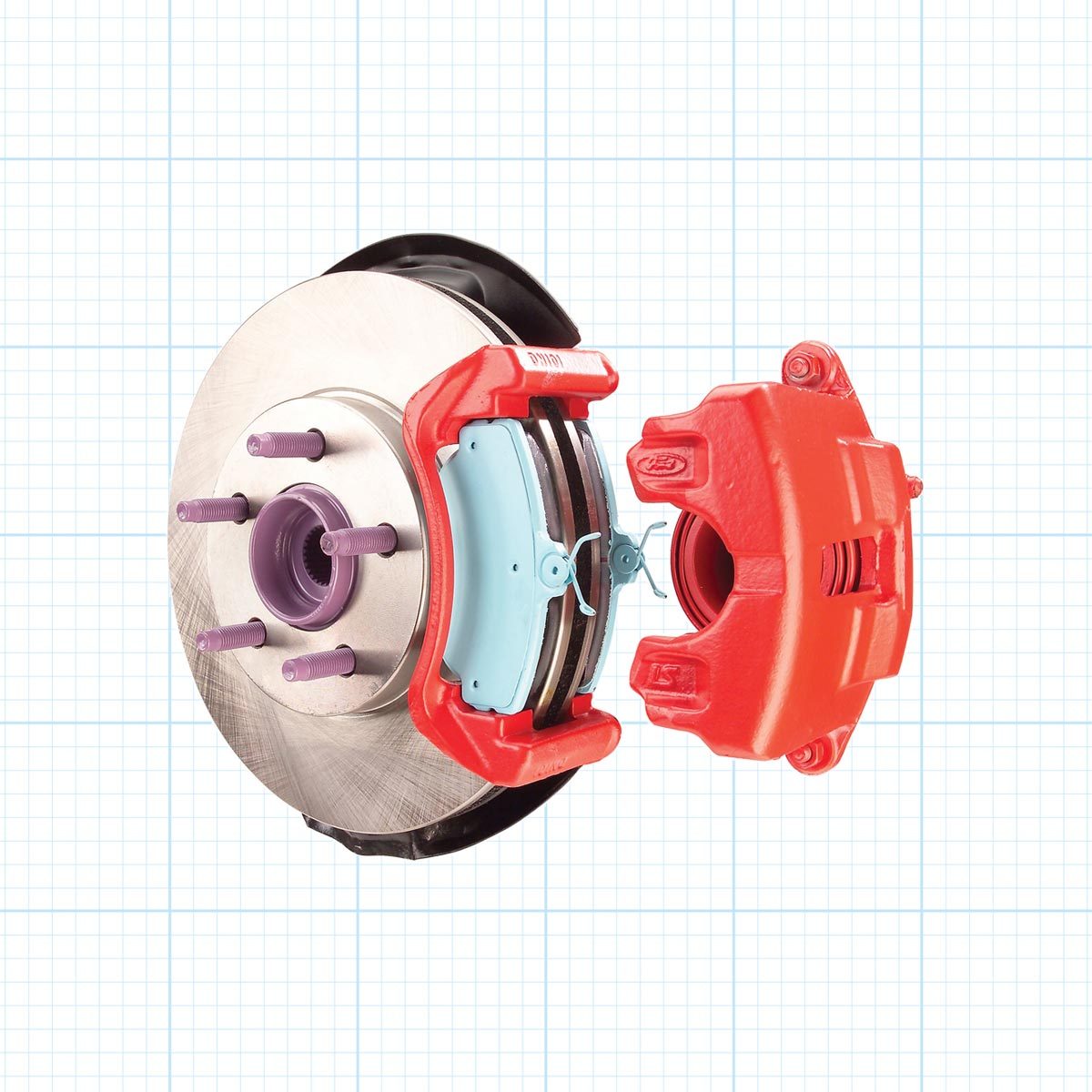

Bolted to the steering knuckle, a brake caliper has two basic jobs: housing friction material (the disc brake pads), and, transferring pressurized brake fluid from the master cylinder through a piston (or pistons) to clamp the brake pads against the disc brake rotor when you push on the brake pedal.

As the pressurized fluid acts on the caliper piston, it squeezes the disc brake pads against the disc brake rotors. The energy of the pads pushing against the rotor generates heat from friction. This heat friction slows the rotor (and wheel) rotation, ultimately bringing your car to a stop.

What Happens When a Brake Caliper Goes Bad?

The first sign that brake calipers are bad is that brake pads and rotors frequently wear out and need replacing. According to ASE Master Technician and Mazda Senior Certified Technician and Trainer Tom Diamond, the leading cause of damaged calipers is driving with overheated or worn-out brake pads or warped disc brake rotors.

Other major causes are worn, loose, defective, missing or unlubricated brake mounting hardware—specifically brake anti-rattle clips, caliper slide pins or shims. Bad caliper hardware will also cause brake pads to wear unevenly and more quickly. Both prevent the brake system from quickly dissipating heat friction, which can damage the calipers. Diamond added, “Cleaning or replacing and lubing caliper hardware is [as] important” as installing new brake pads.

When brake pads fail to insulate the caliper from excessive heat:

- Damaging heat can be passed through the caliper piston to the brake fluid, causing the fluid to degrade and possible brake fade or failure.

- The piston can be damaged, causing it to corrode or get stuck in one position.

- If the piston sticks in the retracted position, that wheel will lose braking ability.

- If the piston sticks in the engaged position, the wheel will lock up or severely overheat until it is released.

How to Tell If a Brake Caliper Is Bad

There are many signs a brake caliper has failed or is failing, including:

- Acrid odors from the wheels

- Brake fluid leaks

- Brake locking up when stopping

- Brake pedal pulsing up and down while stopping

- Collapsed brake hoses

- Dragging brakes

- Excessive brake dust

- Fading brake pedal due to overheated brake fluid

- Longer stopping distances

- Noises (rattling, grinding, squeaking) when driving, turning or stopping

- Overheated brake pads

- Premature or uneven brake pad wear

- Pulling to one side when driving or braking

- Steering wheel vibration when slowing or stopping

How to Maintain Brake Calipers

Diamond suggests regularly inspecting brake caliper hardware (bushings, anti-rattle clips, retainers, insulation shims), mounting bolts, brake pads, rubber components (brake hoses, seals, O-rings, dust boots) for visible tearing, cracking, normal wear and tear, as well as rust and corrosion every time you change oil or rotate your tires.

“Taking a good look at the brake rotors for hot spots, cracks, grooves, scoring, rust, pitting, warping or excessive glazing” will increase driving safety and lessen future repair bills,” said Diamond. Additionally, flushing brake fluid regularly can also help increase caliper life expectancy.

FAQ

How long do brake calipers last?

“It depends,” says Diamond. “There is no recommended mileage or time for replacing disc brake calipers.”

The lifespan of a caliper can be as long as you own your vehicle. However, if you live in the “salt belt,” areas of extreme climate conditions, do lots of off-road driving, drive in harsh, dusty, dirty conditions or mostly stop-and-go city driving, expect calipers to last between 75,000 to 100,000 miles.

In my experience, the main causes of caliber failures are not flushing away road salts, letting brake friction material wear below 4/32 inches (3 mm), hardware corroding from a lack of brake grease, and overtightening mounting bolts.

Can you paint brake calipers (and why)?

“Absolutely!” says Bob Hunter, ASE and I-CAR certified body collision and paint expert. The main reason to paint brake calibers is to make your ride look good. “Consequently,” Hunter said, “painting calipers also protects them against rust and corrosion.”

Where do you use caliper grease during brake job?

When replacing brake pads:

- Apply a coating of brake caliper grease to the caliper, steering knuckle mounting surfaces, contact points, dust boots, bushings, mounting bolt shafts (not the treads) and guide pins.

- Additionally, when installing new brake pads, replace all the brake hardware. If hardware isn’t included with the new pads, buy the direct fit/replacement hardware kit for your vehicle.

- Clean all contact surfaces using a stiff wire brush and flush with non-chlorinated brake cleaner.

- Do not use sandpaper or a wire brush on caliper bushings, or brake hardware made of polished or stainless steel because you’ll break the “hardness” finish by cleaning with sandpaper, file or wire brush. (Once rusted or corroded, they need to be replaced. It is almost impossible to prevent them from rusting in the future.)

- Finally, always use a torque wrench to tighten the caliper mounting bolts.

About The Experts

- Thomas Diamond has over 30 years of experience in the automotive repair industry as a technician, certified original equipment manufacturer (Mazda) trainer and shop supervisor. He has been an ASE Master Technician for over 25 years, including ASE L1 advanced automotive engine performance certification and is a PA Department of Transportation certified state safety, emissions and reconstructed vehicle inspector as well as a certified welder.

- Bob Hunter has more than 30 years of experience as an autobody and painting technician. He is an ASE Master and I-CAR ProLevel Technician, and currently is a Pennsylvania Department of Education certified Auto Collision instructor at North Montco Technical Career Center in Lansdale, PA. During summer break, Bob works in automotive restoration and has restored classic cars that have sold at Barret-Jackson Auctions.

Sources

- Dorman Products, Shop Press: “Rust belt vs salt belt: Do you know the difference?” July 23, 2024.

- Duffy, J. (2014). Modern Automotive Technology (8th ed., pp. 1639-1653). The Goodheart-Willcox Company, Inc., Tinley Park, IL.