Camshafts and crankshafts perform separate functions, but must work together in a well-choreographed sequence for your engine to operate smoothly.

Camshaft vs. Crankshaft: What’s the Difference?

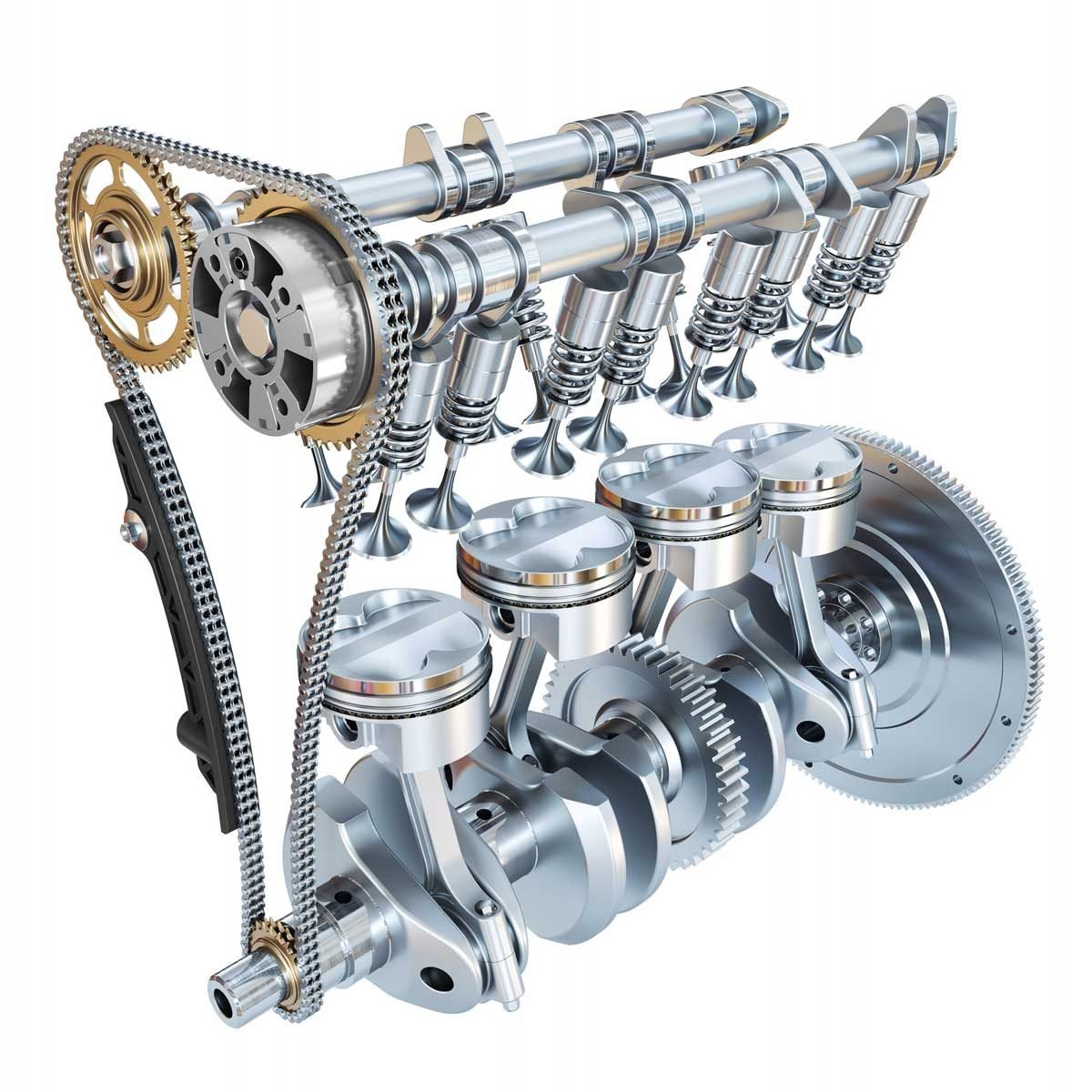

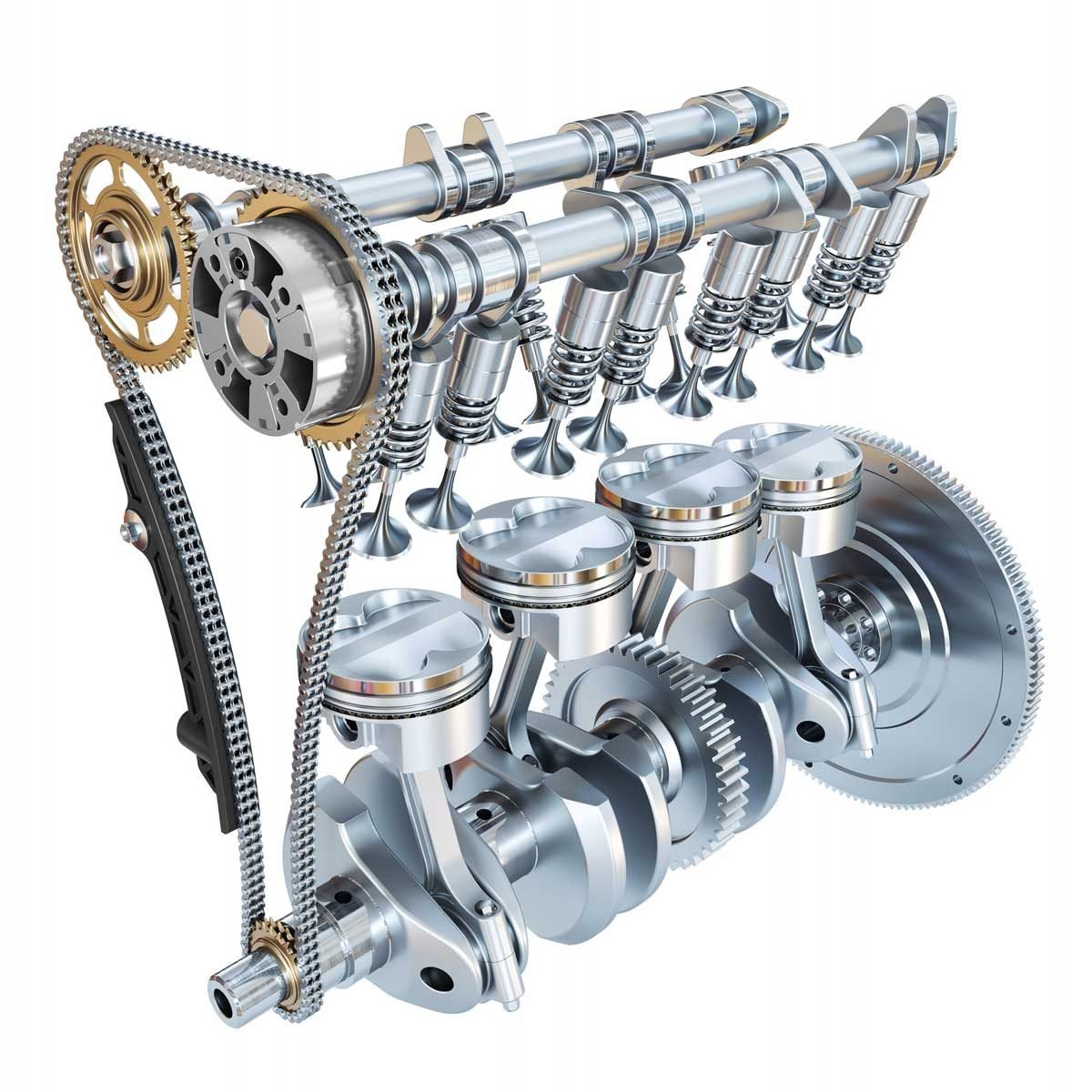

A camshaft uses egg-shaped “cams” to open and close engine valves (one cam per valve), while a crankshaft converts “cranks” (the up/down motion of the pistons) to rotational motion.

On This Page

What Is a Camshaft?

Located in the “top end” of an engine, the camshaft is a critical part of the valve train that allows air and fuel to enter the combustion chamber (the space above a piston) and exhaust gases out after they burn.

A modern internal combustion engine (IC) can have up to four camshafts — or dual cams — with four valves per cylinder (two intake and two exhaust). A single-cam setup has only one of each valve.

How Does a Camshaft Work?

Driven by the crankshaft, a camshaft transfers motion from the cams through various parts of the valve train to open and close engine valves.

Cam lobes come in different shapes and sizes to control how much a valve opens, and for how long. A four-camshaft configuration increases power. With more valves, more intake and exhaust gases can move more easily because there is more space for them to flow through.

What Is a Crankshaft?

Located in the “bottom end” of an engine, the crankshaft harnesses the tremendous force of combustion by thrusting the pistons downward, causing the crankshaft to rotate. This rotation is the power source of an engine.

How Does a Crankshaft Work?

Connecting rods attach pistons to the crankshaft. Combustion, controlled precisely by ignition and valve timing, exerts massive downward pressure on the pistons, allowing the crankshaft to maintain its rotational momentum.

How Do Camshafts and Crankshafts Work Together?

Camshaft and crankshaft gears are connected by a timing chain or timing belt (similar to a drive belt, but with teeth), or a mesh gear set (two interlocking gears) located in the “front end” of an engine. To control combustion they must be indexed (aligned to manufacturer’s specifications) to work in perfect harmony. This is called valve timing.

During the four-stroke combustion cycle (intake, compression, power and exhaust) the crankshaft turns twice — moving each piston up and down twice — while the camshaft turns once. This results in each valve opening one time for every two crankshaft revolutions in relation to the piston. This way, only the intake valve(s) will open on the intake stroke.

Both valves remain closed during the compression and combustion strokes, and only the exhaust valve(s) opens during the exhaust stroke.

Timing belts, chains and gears wear out, so be sure to check your owner’s manual for the suggested replacement intervals.