Make a Small Workshop Feel Bigger

For most of us, a big shop is only a dream. Too often we’re forced to build our ambitious projects in a small wood shop fit only for building birdhouses. In spite of its postage-stamp size, you can still churn out dining room tables, kitchen cabinets, library shelves and other major projects.

The keys to making big things in a little shop are organization, out-of-the-way storage, and nesting or collapsible work surfaces. If your shop and tools are small but you dream large, here are some workshop ideas that will help.

Air-Compressor Loft

Air compressors — even small ones — take up a lot of valuable space. To preserve every square inch of floor space, build a little corner shelf overhead. Nestle your compressor into a corner of the floor and measure the size of the shelf you need to fit it. Leave an extra two inches of room at the front where you can screw on a 2×2 lip to “corral” the compressor so it won’t walk over the edge while it’s running. Then measure the height of the compressor to determine the proper distance from the ceiling to the shelf so the compressor has enough clearance.

To build the shelf, start by fastening 2×6 ledger boards to the studs with 5/16-in. x 4-in. lag screws driven into each stud. Screw down a chunk of 3/4-in. plywood on top of the 2x6s for the compressor floor and another chunk on the underside for a storage shelf. A strategically placed three-inch hole makes it easy to drain the tank from underneath.

To really complete this air tool station, solder 1/2-in. copper tubing and attach it to the compressor with a swivel “snubber” hose. Connect an air hose reel for compact hose storage for long-distance needs and a curlicue-style hose for air-at-your fingertips bench work.

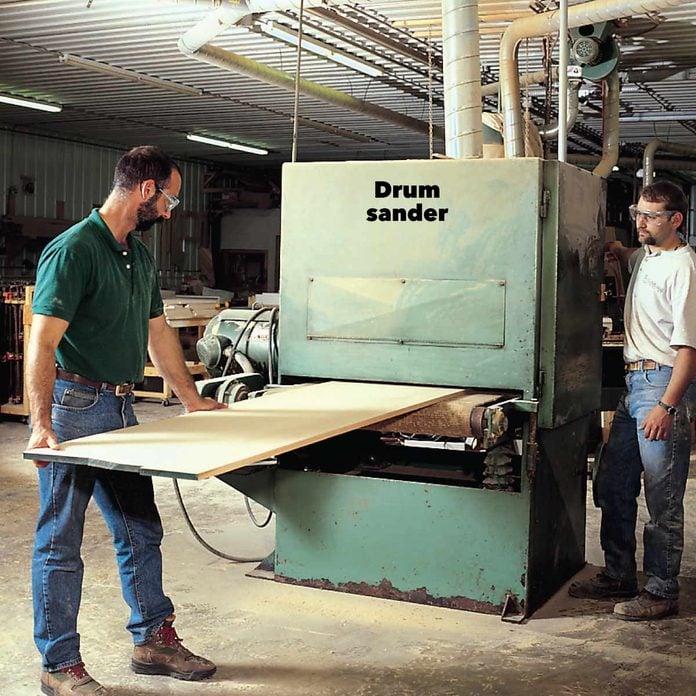

Pay for Woodworking Services

A small shop can’t handle everything. Most stationary tools are expensive and space hungry, but they can save hours of time over smaller tools like hand planes and belt sanders. When you need an occasional helping hand, find a cabinet shop that’s willing to plane, sand, shape and rip the work that you bring in.

For example, the wide belt sander pictured above will do a perfect job of leveling a glued up tabletop in minutes — and you can usually have it done for under $20. A friendly relationship can also pay off with advice on things like joinery techniques, and as a source of raw materials or hardware.

Use Collapsible Work Surfaces

You may not have room for a permanent assembly table, but you can always clear a spot for this temporary folding one. Buy a pair of collapsible sawhorses. Screw an old or damaged door (lumberyards often have rejects at rock-bottom prices) to the top of the horses. Screw two 1-5/8-in. drywall screws up into the edges of the door at the end of each horse. The result is a large workspace that folds up and takes little room to store. You’ll have the whole thing set up in about 60 seconds!

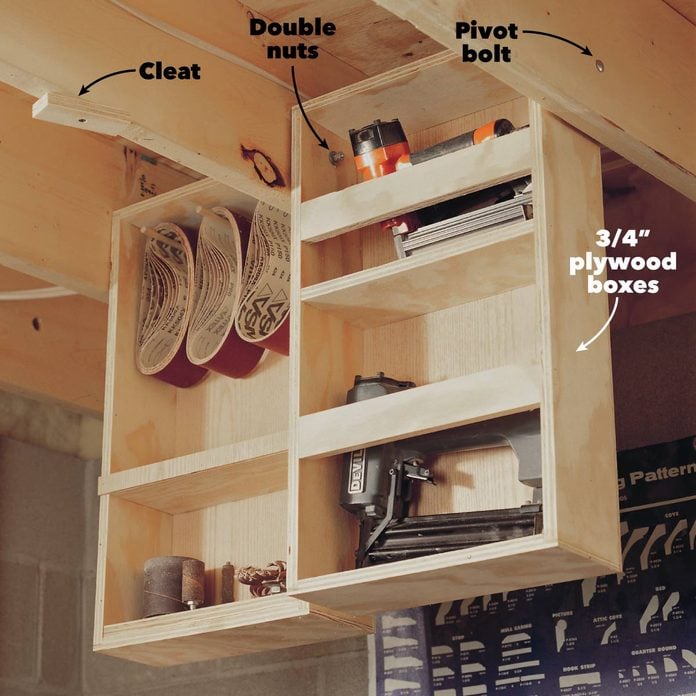

Ceiling Drawers

Utilize every cubic inch of storage in a basement shop with pivoting boxes that hang between the ceiling joists. When a drawer is down, you have easy access to its contents. Use glue and 1-5/8-in. drywall screws to hold together the boxes, then customize shelving for whatever you want to store. Make the width is about 3/8-in. narrower than the cavity it fits in, and use double-nutted 3/8-in. x 3-1/2-in. carriage bolts for the two pivot points.

Two plywood cleats pivot on three-inch screws to hold each drawer in place in the “tucked” position. The drawers are perfect for anything you only need occasionally. But be careful to keep contents relatively light so you can safely open and close the drawers. It’s definitely not the place to store your anvils.

Pegboard Shelving

Panel your shop with pegboard instead of drywall or plywood and you’ll have endless storage space to hang hand tools, no matter how small your shop. Homemade shelving that’s specifically for pegboard takes the concept one step further.

Use 2x4s and 1/4-in. L-hooks to make the shelves. Chamfer the top back edge so the shelf can be tipped in, and tighten the L-hooks for a snug fit against the pegboard. Predrill the edges of the 2x4s with a 3/16-in. drill bit. About every six inches, screw in threaded two-inch L-hooks to match the holes in your pegboard. These shelves are surprisingly strong and can be sized to fit your specific needs.

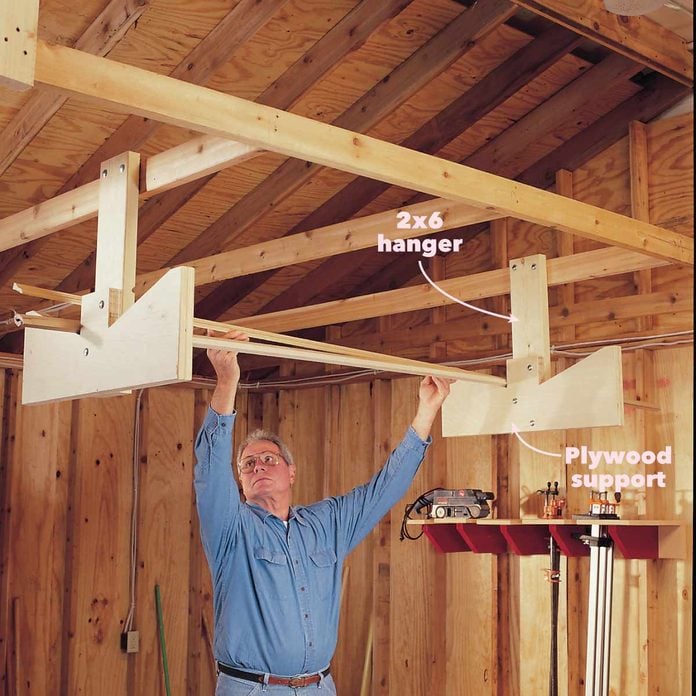

Small Woodshop Lumber Storage Ideas

The perfect place to store small quantities of long, narrow offcuts and moldings is right over your head. Build this set of overhead storage racks in a high basement ceiling or in the open trusses of a garage shop. Use 2x6s for the vertical hangers and doubled-up 3/4-in. plywood for the lower angled supports. Secure each 2×6 into the framing with two 5/16- x 3-in. lag screws. Screw each hanger into the 2×6 with two offset 5/16- x 3-in. lags. The angle on the supports keeps the boards from sliding off. This is one of our favorite (and super-simple!) lumber storage ideas.

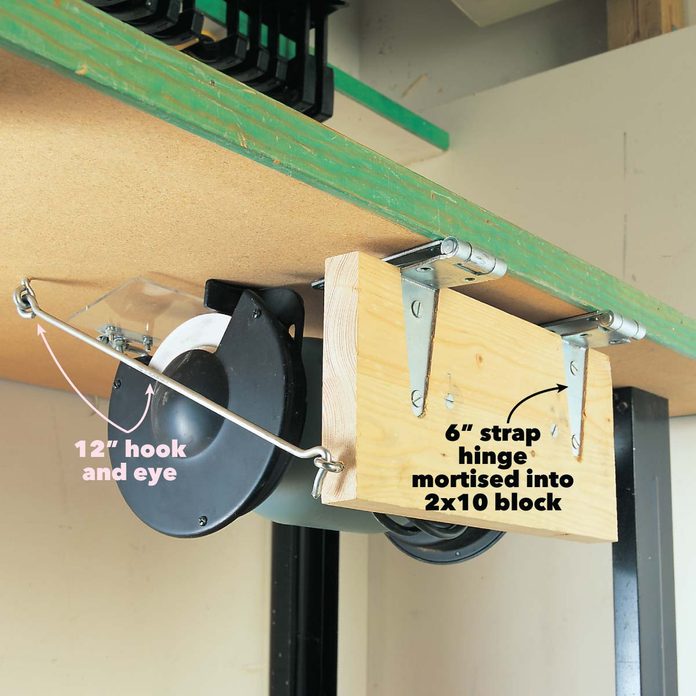

Swing-Up Grinder

Grinders are great tools. But if your shop is cramped, their occasional use doesn’t justify a permanent corner of your workbench. Try hinging your grinder to keep it handy but out of the way when not in use. A pair of six-inch strap hinges and a 12-in. hook and eye with an extra eye bolt are all you need to build this swing-up grinder base.

First, bend one strap of each hinge. Hold the hinges in place and mark the bend. Then clamp each hinge in a vise so the mark is just above the jaws and hammer it over. Mount the grinder on a block of wood and mortise in the hinges with a router or chisel so the block sits flat on your bench. Add an eye bolt toward the back of the block and mount the hook and eye under the bench top to hold the grinder in place when it’s stored.

Nesting Stools

Lowboys, stools or crickets — whatever you call them, these shop stools are amazingly strong and versatile.

There are four separate lengths for the tops and sides for four different-sized lowboys. You can make all four “boys” out of one sheet of 3/4-in. plywood. The progressively larger sizes allow them to nest for storage, making them perfect for a cramped shop. The 16-in. height is great for large projects that might not fit on a normal sawhorse. For working around the house, that extra height makes it easy to reach ceilings.

If that’s not reason enough, when your buddies come over to help you cogitate the finer points of your next project, there will be plenty of seating.