Easy-Open Nozzle

Sometimes it’s hard to pull open the nozzle on a bottle of wood glue, so cut a small piece of wood with a hole in the middle and install it between the nozzle and the bottle. The wooden handle is much easier to grab and pull open.

Portable Hot Glue Hack

Sometimes you only need a little dab of hot glue to fix something. Melt the tip of the glue stick with the lighter and dab the melted glue on your repair.

Paste Wax Makes Cleanup Easy

Here’s a great way to minimize the mess when re-gluing joints— just rub a little paste wax on the finished surfaces next to each joint. This makes cleaning up squeezed-out glue a snap because the glue won’t stick to the wax.

Why You Should Lubricate Your Glue Caps and Lids

Caps on certain adhesives/glues, like rubber cement and super glue, have a habit of getting stuck or glued on no matter how hard you try and keep them clean. This can be prevented by simply smearing a little coating of petroleum jelly onto the threads of the tube or lid. You just need a small dab of petroleum jelly to prevent even more of a mess.

Be sure to smear a little bit on before putting the cap back on the glue to prevent the cap from cementing over time. Next time you go to use your super glue, you’ll be able to open it with ease and get right to work!

Use a Straw to Scoop Up Squeeze-Out

When glue squeezes out on a woodworking project, using a chisel to scoop it out has the potential to mark-up and scratch the adjacent surface. The solution is a simple drinking straw, which will conform to the shape of the corner and collect the excess glue.

Glue Bottle Caddy

Here’s how to build this glue caddy for your shop:

-

- Arrange all your glue bottles in a circle with 1-in. spacing between the bottles.

- Add 2 in. to the circle diameter and cut out two 3/4-in. plywood discs.

- Drill 7/8-in. holes in the center of each one.

- Measure the various bottle diameters and drill storage holes around the top disc a smidgen larger than the bottles.

- Glue the discs on a 12-in.-long, 7/8-in. dowel, with a 5-in. space between the discs.

Easy Drip Cleanup

Here’s how to avoid scraping hardened glue off your workbench. Before you set up for gluing, lay a sheet of inexpensive, thin painter’s plastic underneath. Another nifty tip to avoid rockhard glue on your workpiece is to glue it, then wait two hours and scrape off the excess. The glue is still pliable at this stage, so the job is quick and easy.

Quick, Even Application

Here’s a smooth tip for spreading carpenter’s glue. Slide a piece of 1-in. diameter pipe insulation onto a 4-in. paint roller frame and use it to evenly roll on the glue. When the job is done, just throw away the insulation. No more wasting store-bought rollers on a one-time job.

Caulk Gun Clamp

Did you know that you can use a caulk gun as a clamp? It’s perfect for gluing up small projects such as a cutting board. Just place a couple of pieces of scrap wood or cardboard at the ends of the caulk gun and then squeeze the trigger to apply pressure.

Don’t Let Glue Freeze

Many adhesives–wood glue especially–can be ruined by just one freeze/thaw cycle, so it’s a good idea to store them in a heated space during cold months. Even glue just left overnight in a car can freeze and make it unusable.

Mustard Bottle for Glue

Don’t put up with the messy “over-designed” carpenter’s glue dispensers. Instead, use old mustard bottles. They don’t clog and can easily reseal between uses.

Mix Epoxy With a Can

Use an aluminum can for mixing epoxy in a pinch. The smooth metal surface has a concave shape, and it also has a small lip all the way around the edge. Better yet, when you’re done mixing and applying the epoxy to your project, allow it to dry. Then the epoxy can be easily peeled off and you can reuse the can for your next glue-mixing task!

Repurposed Refiller

If you’re in need of an easy-to-make, disposable funnel, we have the perfect solution for you. Simply cut off the handle from a gallon water (or milk) jug, and use this to serve as a disposable funnel. This funnel will help you to drain anything from your leftover wood glue to the old oil in your snow blower.

Edge-Gluing Made Easy

These clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and stay level. Here’s how to make them:

- Drill 3/8-in. holes (spaced 1 to 1-1/2 in.) along 5-ft. of hard maple 2x2s.

- Cut two 3/4-in. x 8-in., 20-degree tapered wedges for each clamp. B

- Buy six 5-1/2 in. x 3/8-in. carriage bolts, washers, and wing-nuts.

- To set up the clamps for gluing a panel, slide the boards you’re gluing into the clamps without glue.

- Push the bolts into the holes, allowing space for the wedges to be hammered in between the bolts and boards.

- Slide out the boards, apply glue to the edges, and put them back in the clamps.

- Tap in the wedges while checking along the joint lines to make sure the surface is even.

Free Glue Spreaders

Pick up a few free laminate samples on your next trip to the home center and put them to work as glue spreaders, nailing shields, shims, scrapers and spacers. Use them once and you’ll discover a dozen other ways they can improve shop life.

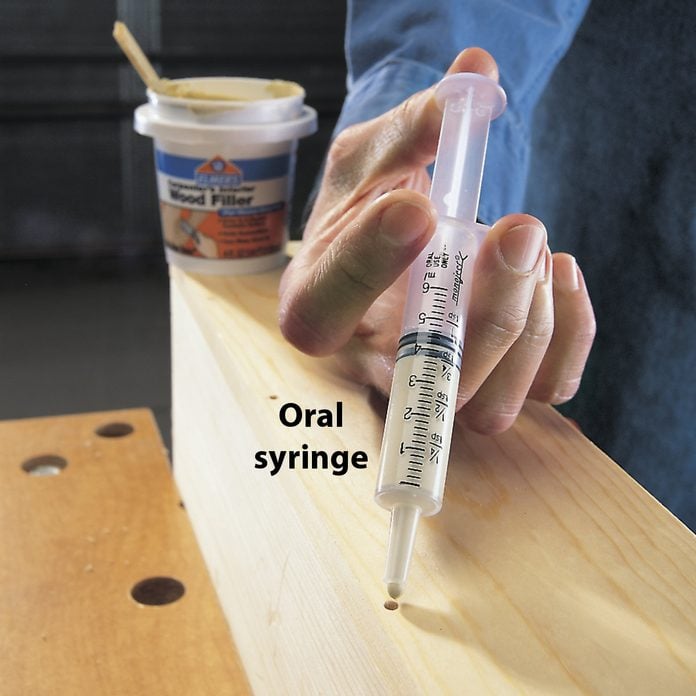

Precise Gluing Tool

Oral syringes are perfect for injecting wood glue into narrow crevices for furniture repairs. Hot water cleans the syringe in a flash.

Moldable Clamps

Here’s how to make glue repairs on small or delicate objects without having to hold them together by hand until the glue dries. Flatten out a ball of Play-Doh modeling compound, glue your project, and press it into the clay. It’ll hold the pieces together until the glue dries!

Keep Disposable Mixing Cups at the Ready

Load a Dixie Cup dispenser with 3 and 5-oz. paper cups and keep it handy for all kinds of jobs. Mix epoxy, measure and stir finishes, hold glue, keep track of parts from disassemblies and hold paint for touchup jobs.

Scrape Glue While it’s Soft

At room temperature and average humidity, squeezed-out glue will be ready to scrape in about 20 minutes. Wait until the glue changes from liquid to a jelly-like consistency. Then scrape it off with a putty knife. If the clamps are in the way, you can safely remove them after about 20 minutes in normal conditions. Handle the glued-up panels carefully, though, since the glue won’t reach maximum strength for several more hours.

Glue Up Picnic

A vinyl tablecloth—any size—comes in handy for all kinds of woodworking jobs. Put it under boards you’re gluing together. Any glue drips will easily peel off the plastic surface after they dry.

Guitar Picks in the Workshop

They’re practically perfect for applying wood putty to nail holes and scraping squeezed-out glue from project corners. Use one any time you need a mini scraper or spatula.

Project Pedestal

This gluing pedestal makes clamping from all angles a breeze. Buy a 12-in. pipe nipple with pipe flanges on both ends and screw it to a couple of scraps of 3/4-in. plywood. Cut the pedestal top an inch or so bigger than the project to make clamping easier. Now, with the base of the pedestal clamped on your workbench, you can crank on the clamps from every angle.

Craft Sticks to the Rescue

Craft sticks and tongue depressors are handy for all kinds of shop tasks. Use them to spread glue, mix stain and epoxy, measure and transfer a cutting width, pad those metal vise jaws (hold them in with carpet tape), push putty into nail holes and hold little brads for nailing. Keep them conveniently stashed around your workshop—you’ll be surprised how often you reach for one.

Tin Can Glue Bottle Storage

Reuse a tin can for storing glue bottles upside down in your workshop. Then you won’t have to wait for the glue to slowly reach the top of the bottle in order to squeeze it out—it’ll be ready to go when you reach for it.

Quick Edge Glue Cleanup

To avoid the hassle of cleaning and scraping dried glue when edge-gluing boards together, press masking tape along both edges of the boards before putting on the glue. This way, the glue will ooze out onto the tape instead of the wood when you tighten the clamps.

Workshop Skewers

Some brilliant uses for barbecue skewers:

- Puncture that pesky seal in caulk tubes.

- Apply glue in dowel holes or biscuit slots.

- Scrape gunk out of crevices on furniture you’re refinishing.

- Plug stripped-out screw holes on antique furniture so the screws will grip tightly.

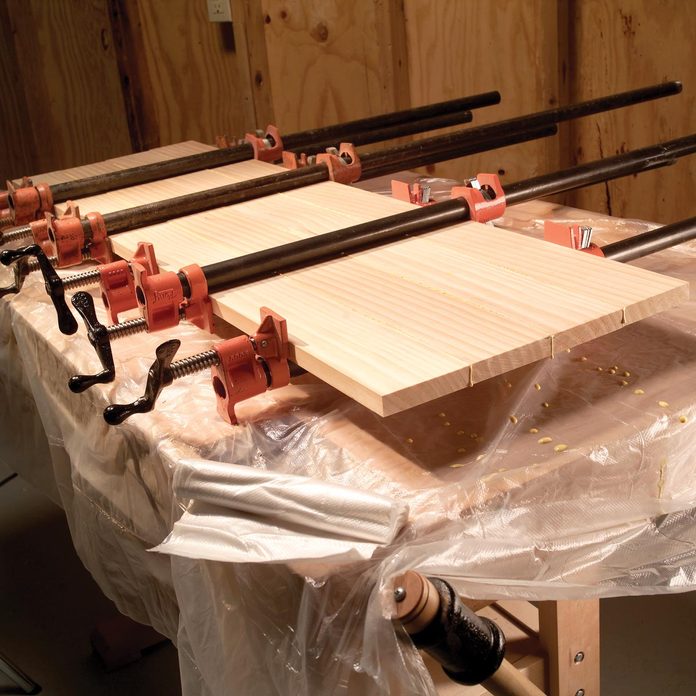

No-Mess Board Gluing

Tired of scraping dried glue from your workbench and clamps? Shop teacher John Nelson’s no-mess technique also ensures a flat finished surface when you’re edge gluing boards.

First, cover the clamps with newspaper. Then smooth glue on the board edges and lay them into the clamps without tightening. Fold the newspaper over both ends of the panel and lightly clamp 3/4-in. x 1-1/2 in. wide hardwood batten boards above and below each end with C-clamps. Now alternately tighten all the clamps (all the bar clamps first, then the C-clamps). The batten boards keep the boards from sliding up and down as you tighten the larger clamps, so the boards remain in the same alignment as the glue dries.

After 20 minutes, peel off the partially hardened glue on top of the panel with a paint scraper. The newspaper under the tabletop prevents the metal clamps from staining the wood where they touch glue, and it catches squeezed-out glue so the workbench stays clean.

Glue + Sawdust = Wood Filler

When you need wood filler that matches the color of your project, mix some fine sawdust and glue together until it forms a paste, which you can use to fill small gaps and cracks. For best results, use sawdust from the same species of wood as your project; you can get some from the bag on your electric sander. Just don’t try this trick for large gaps or patches—they’ll stick out like a sore thumb.

Handy Handscrews

Glued-up strips of wood like to drift as you tighten clamps. To prevent this, you can lightly snug a handscrew parallel across the edges as shown (don’t forget the wax paper) and then tighten the other two clamps for a perfectly aligned glue-up.

Seal Outdoor Furniture Feet

Keep wood outdoor furniture kicking for as long as possible by protecting the surfaces that come in contact with the ground—especially end-grain pieces. Mix up a batch of epoxy and spread it evenly along the feet of, in this case, a wood bench. Allow the epoxy to dry completely, forming a weather-resistant seal, before placing the bench outdoors.

Fix Cracks with Floss

It’s easy to coat narrow crevices with glue when you’re repairing a cracked board or tenon on a project. Pour a little carpenter’s glue on a scrap of wood, drag the unwaxed floss back and forth through the puddle, and floss the glue into the crack. Now clamp the crack closed and let it dry.

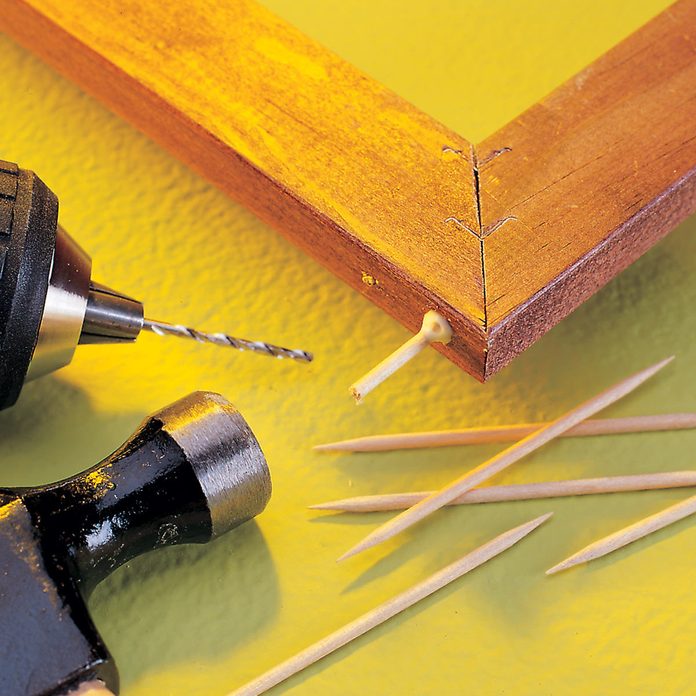

Tiny Dowel Trick

Round toothpicks work great for locking the mitered corners of picture frames. When each corner is cut and glued, drill pilot holes (the same diameter as the toothpick) from each side of the corner. Apply glue to the toothpick and tap it into the hole. When the glue sets, cut the excess toothpick flush with the frame, and then stain or paint it to match for a nearly invisible fastening job.

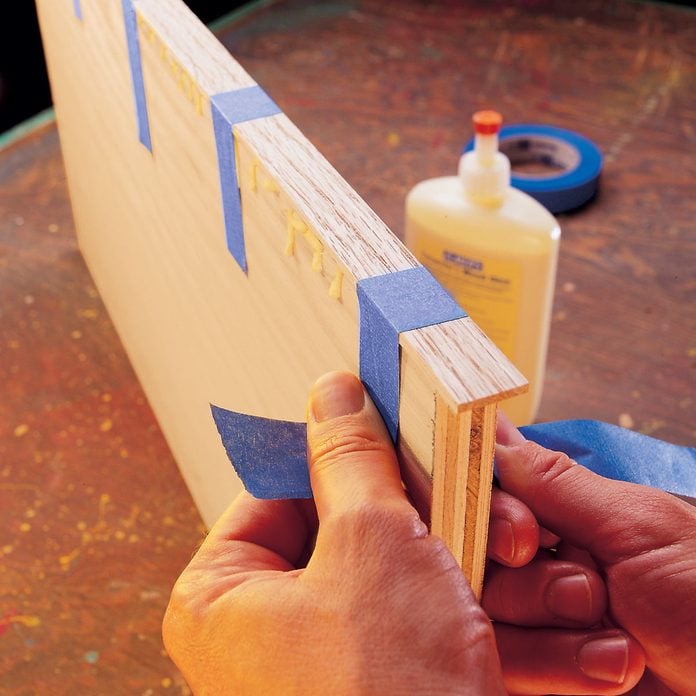

Tape Does the Trick

There’s no better way to clamp wood edging strips to plywood shelves than with pieces of masking tape. Just apply your glue to the backside of the strip and secure it with pieces of tape every 3-in. or so. Always cut your edging an inch longer to save the hassle of trying to align the ends perfectly. The excess length is easy to trim off later with a fine-tooth handsaw.

Always-Full Glue Bottle

Is your glue bottle half full or half empty? Now no matter how much glue is in the bottle, it seems like it’s full because when you store the bottle upside down in this handy stand. To make it, take a 3 x 3-in. block of wood and drill a 1-1/4 in. hole in the middle a little deeper than the wide part of the cap. Then drill a 5/8-in. hole for the neck as shown.

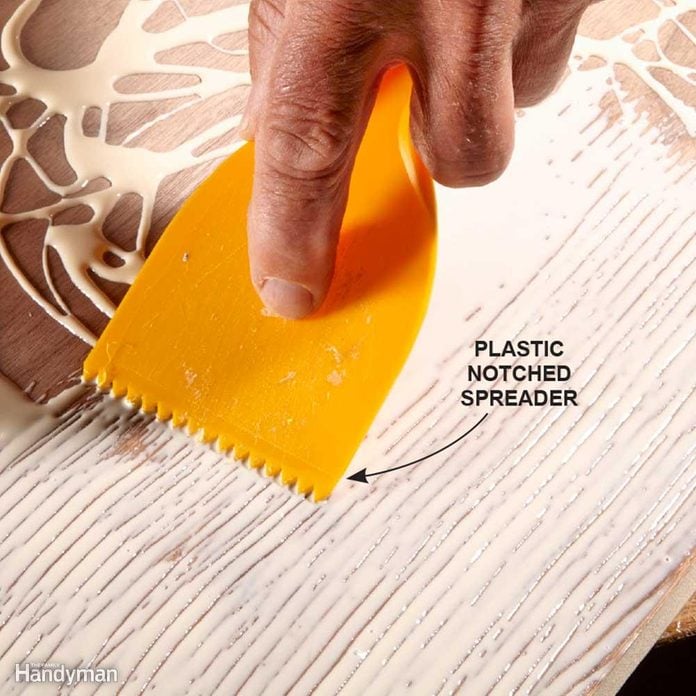

Spread Glue With a Notched Trowel

When you’re gluing large surfaces, an inexpensive notched plastic trowel works great for spreading the glue. To find one, look in the flooring or tile section of the hardware store or home center. If you’re fortunate enough to have a pair of “pinking” shears in the family sewing basket, you can make our own spreader from an expired credit card.

Worm Blower Glue Injector

Use a Worm Blower to inject glue when repairing splits and cracks in projects. The air-powered needle tip shoots glue deep into the crack for a long-lasting repair. Just be sure to clean the glue from the syringe tip by squirting hot water through it when you’re finished.

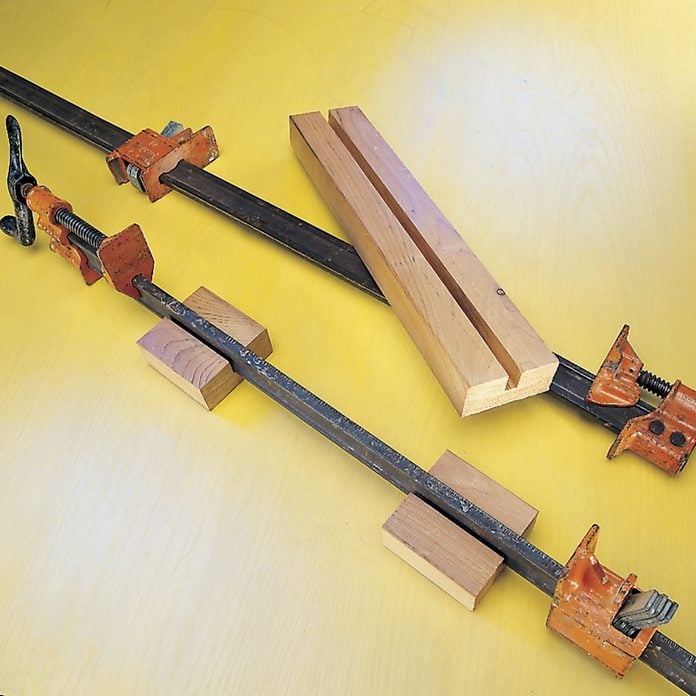

Big Clamp Stabilizers

These grooved blocks will hold the bar clamps upright so they won’t flop over when you tighten the boards in the clamps. Here’s how to make them:

-

- Use your table saw to cut a 3/4-in. deep slot midway along the face of a 2×4. You want a snug fit for the bar, so stop and test-fit it in the slot as you widen the slot with additional passes.

- Crosscut the slotted 2×4 into 4-in. long blocks.

- Press the bars into the slots.

E-Z Bottle Caps

A medium-duty E-Z Ancor is the best glue bottle cap we’ve found. The narrow rectangular tip seals the opening of every glue bottle we tried. And the E-Z Ancor is much larger than the cap—so it’s that much harder to lose.

Cauls Keep Glue-Ups Flat and Flush

As you squeeze boards together with pipe clamps, they sometimes arch or slip out of alignment. Pairs of upper and lower cauls can help with this. Lightly squeeze the cauls with bar clamps, then tighten the pipe clamps, then tighten the cauls a bit more. Continue this back-and-forth process until the boards are joined flush and flat.

Flux Brush Applicators

Keep a few plumber’s flux brushes ready for spreading glue on your projects. They’re perfect for brushing on just the right thickness of glue. Bend the handles into U-shapes so you can hang the brushes on the edge of a jar half-filled with water to keep them from drying out. There’s also no cleaning needed— just wipe off the excess water with a paper towel before use.

Cinching that’s a Cinch

Octagonal, hexagonal and even square pedestal bases for tables can be aligned perfectly for gluing with heavy-duty plastic sealing tape. Cut your bevels on the workpiece edge and lay them with the inside face down and one end butted to a straightedge. Align the bevels so they touch along their entire length and tape them securely. Next, carefully flip them over and apply glue to the joints. Then stand them up, fold them together, tape the final joint and pull the shape together with belt clamps.

Quick Covers for Handscrews

Handscrews are the pros’ choice for clamping face-glued boards and laminates. The only drawback is that the handscrew jaws can load up with glue, and if you’re not careful, they could become a permanent part of the project! Here’s the solution:

- Wrap duct tape or clear packaging tape around the handscrew jaws to keep glue from penetrating and adhering to the clamps

- Remove the clamps once the glue is set but still pliable. Use a moist rag to clean the glue off the taped handscrews, or strip off the tape and apply new tape before your next messy job.

Toothbrush Glue Spreader

Old toothbrushes are great for gluing and avoiding a mess. When your toothbrush wears out, put it back into service as a glue spreader. Use a toothbrush to apply glue to boards for edge-gluing. No more spreading glue with my fingers or chips of wood. The soft (but not mushy) bristles of an old toothbrush apply glue evenly and quickly. One swipe along the edge usually does the trick, coating the surface smoothly and evenly. Store the brush in a glass of water.

Hard-to-Clamp Repairs Call for Hot Glue

When you need to glue parts that can’t be clamped together, hot glue is the answer. Hot glue will set in just a few seconds while you hold the pieces together.