How to Build a Miter Saw Table

Updated: Jun. 14, 2023

Make your own pro-grade miter saw/work table

A half day

Beginner

$100 - $150

Introduction

Miter saw stands are an essential, but expensive accessory for carpenters. Instead of buying one, save money and get a more versatile work table by building your own. Use these photos and free plan as a guide.Tools Required

- Circular saw

- Clamps

- Cordless drill

- Drill bit set

- Framing square

- Level

- Miter saw

- Safety glasses

- Socket/ratchet set

- Table saw

- Tape measure

Materials Required

- 4' x 8' sheet of 3/8" BC plywood

- 6'-long 1x4s (2)

- 8'-long 1x6s (1)

- 8'-long 2x4s (2)

- Hanger bolts

- Small box of 1-1/4" screws

- Small box of 1-5/8" screws

- wing nuts and acorn nuts to fit mounting holes in saw.

If you’ve ever used a miter saw to cut long, unsupported stock, you know what a hassle it is to deal with a saw that moves all over the place while you’re trying to make cuts. Yes, you can buy saw stands, but they’re expensive and, frankly, not nearly as versatile or user-friendly as this homemade miter saw table.

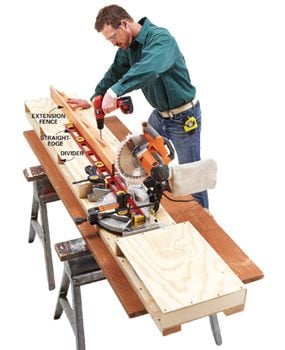

This miter saw table supports long boards and provides a fence that you can fit with stops for making repetitive identical cuts. It locks down your saw so it won’t budge while you’re working. Built-in cubbyholes give you a place to store all those little parts and tools that go with any carpentry task. Just leave the saw on board and slide the whole unit into your pickup truck for on-the-road jobs. Or loosen the wing nuts, remove the saw and haul it away on its own. This table is also a great workbench for more than just cutting. You’ll find it a useful platform for all those little carpentry tasks that are part of any project, and it’s right there where you need it.

This design will work for any miter saw. We’ll show you how to customize it to fit whatever saw you have. As for tools, you’ll only need a table saw to rip the plywood and dividers (Figure A) to width, your miter saw to cut the parts to length, and a screw gun to screw the whole works together.

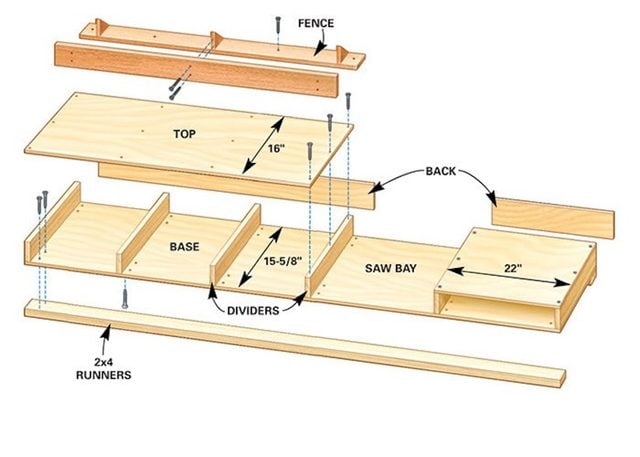

Figure A: Miter Box

The basic design is simple, and the parts are all made from inexpensive, standard lumber.

Buy the materials

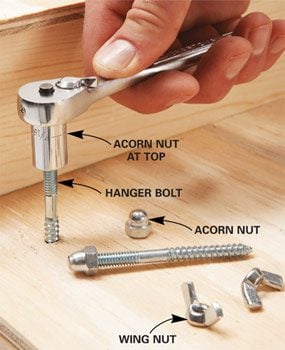

Measure the diameter of your miter saw mounting holes before you get started. You’ll need to buy hanger bolts with matching wing nuts the same size as the holes for a snug fit. Find the right bolt length by measuring the height of the saw table and adding 2-1/2 in. With the bolt size figured out, head to the home center and pick up your bolts and the other items on the materials list.

Project step-by-step (4)

Cut the Parts

Start by ripping the plywood to a 15-5/8-in.-wide piece for the bottom and a 16-in.-wide strip for the top.

If you don’t have a table saw capable of ripping that wide, just snap lines and do the cutting with a circular saw and a steady hand. Don’t worry too much about perfect cuts; small variations won’t affect the project. Hold off on cutting the top to length until you get the dividers positioned later.

You’ll cut the 1x6s into six 15-5/8-in.-long chunks for the dividers and then size them for width. (Allow for the top thickness by putting a chunk of 3/8-in. plywood underneath the 1×6 as you mark.)

Rip one of the dividers and stand it next to the saw. Check it for height with a straightedge resting on the saw table before you cut the other five.

Assemble the Table

Start the assembly by laying out the divider positions. Plan on a 22-in. length for the tabletop on the right side of the saw.

Then size the miter saw bay by examining your miter saw. Pivot the saw right and left, and make sure that you plan a bay that’s wide enough to clear all of the moving saw parts. The left side of the top will be whatever remains.

Simply space the middle dividers evenly on the left side. Screw the dividers to the base and then flip over the assembly and screw the base to the 2×4 runners.

Measure the final height of the table without the top and rip the plywood back pieces to fit, then cut them to length. Screw the back and top to the dividers.

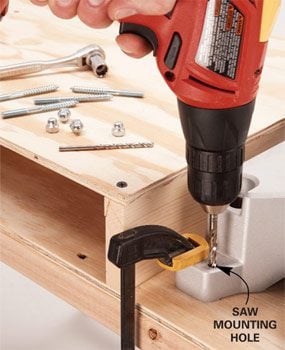

Mount the saw

Center the saw in the bay and clamp it in place.

Drill 1/8-in.-deep holes to mark the hanger bolt positions using a drill bit that’s the same diameter as the saw’s mounting holes.

Then remove the saw, drill pilot holes and drive in the hanger bolts.

Buy hanger bolts that fit the size of the mounting holes. Either use acorn nuts or tighten two nuts against each other at the top of the machine threads to drive in the bolts.

Drop the saw over the bolts and lock it in place with wing nuts.

Build and Mount the Fence

Cut two 1x4s to the same length as the left side of the top. Use the waste to cut four triangle braces.

Screw the two 1x4s together and then evenly space the braces and screw them to each 1×4.

Align the fence with a straightedge lined up to the miter saw fence, and screw the fence to each divider. Use 1-5/8-in. screws for all of the fence assembly.

While the fence provides a handy rail for stop blocks when you need to cut a lot of identical parts, you’ll find that you’re usually better off with it removed. That’s because boards are rarely straight. And if you try cutting a long board that’s bowed toward you, the fence will prevent it from fitting tightly against the miter saw fence for a good, square cut. So, leave it off for everyday cutting—screw it on only when you need it.