5 Must-Have Drill Attachments

Updated: Oct. 01, 2018These five gadgets are proven timesavers and problem solvers

Make your drill do more than drill holes. These five drill attachments are problem solvers and timesavers. Plus, they will work with cordless or corded drills.

Just when you thought you couldn’t possibly find more uses for your drill

When I bought my first drill, I used it for one purpose—to drill holes. Eventually, I found it efficient to have a designated toolbox—my drill kit—to carry that drill and a few drill attachments gadgets directly to a task. Over the years, I’ve tried lots of drill gadgets. Most settled to the bottom of my toolbox and stayed there.

But five accessories stayed in my drill kit because they have proved their worth as both timesavers and problem solvers again and again. One advantage of these tool accessories is that you can use them with either corded or cordless drills. In addition, they’re cheap and can be obtained at most hardware stores, lumberyards and home centers.

Depending on your skill level and range of tasks, you’ll soon develop a feel for what drill gadgets work best for you. Here are my favorite drill attachments:

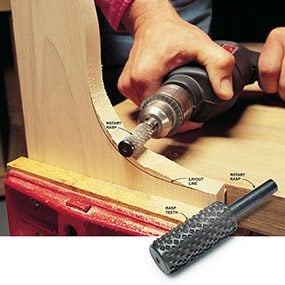

Rotary rasp

After boring a large hole or cutting a pattern in wood, what’s your option when you need to take off a “little more”? I’ve found a rotary rasp drill attachment to be the best choice. It grinds wood and plastics (if they aren’t brittle) equally well. To remove a lot of material, lean on the drill as you work. The rotary rasp isn’t a finishing tool. You’ll have to use a file and/or sandpaper to smooth any marks that show.

Self-centering hinge bits

Drilling pilot holes for hinge screws used to be frustrating and slow. Some of the time, my shaky hand-delivered an off-center hole that resulted in screws that didn’t seat properly in the hinge plate. That all changed after I discovered this godsend. Self-centering hinge bits come in different fixed sizes to fit individual screw sizes. One size doesn’t fit all, but the two medium-sized (No. 5 & 6 and No. 8-10, corresponding to standard screw sizing) bits can handle most doors plus kitchen and bath cabinets.

Simply guide the tapered nose of the self-centering bit into the countersunk rim of your hinge. Turn on the drill and push. A hidden spring inside the device compresses, the drill bit drives forward, and voila—a perfectly centered hole the correct diameter for your screw.

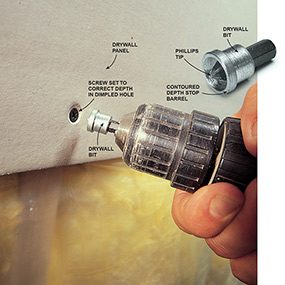

Drywall bit

Screw guns are the best tool for driving screws for a room-sized drywall job. But when you’re hanging only a couple of sheets or need to anchor a 4×12 panel to the ceiling with the first few screws, a drywall bit in a cordless drill is the only way to go.

The drywall bit’s contoured barrel ensures that the screw will be driven the correct depth into the panel. The panel face will be dimpled but not weakened—ready for drywall taping. For this reason, the drywall bit is a better choice than a magnetic bit holder loaded with a Phillips tip. With a bit holder, many times the screws will be driven too deep. When that happens, the paper face on the panel breaks and the screw won’t hold the weight of the panel. Another screw will have to be properly driven adjacent to the first. Imagine doing that repeatedly, while holding a panel against a ceiling, as your arms turn to rubber. Then invest a few dollars and add this bit to your drill kit.

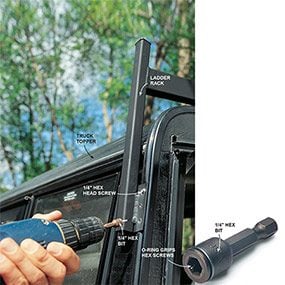

Hex bit

Joining sheet metal, repairing appliances and driving certain concrete fasteners can all be simplified and sped up by adding a hex bit to your drill kit. Each hex bit drives one fixed size of hex head screw. Depending on the number of these separate sized fasteners you encounter, you may either need one bit or a set. The most common size is for a 1/4-in. hex screw. Shop for hex bits with an O-ring “gripper” feature that holds the screw firmly as you position and drive it.

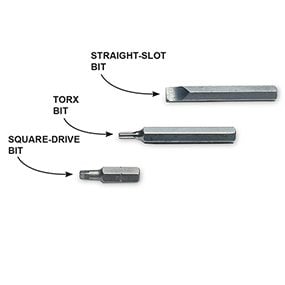

Magnetic bit holder and bits

Next, to drill bits, a magnetic bit holder is chucked in my drill the most. Bit holders save a ton of time by quickly accepting a variety of screwdriver bits. The bit holders come in different lengths. A 3-in. model works well for installing a new door handle without scuffing it. Longer bit holders are available to reach deep into inaccessible niches.

I buy only magnetized holders, which better grip both the inserted bits and the screws they drive. This lets me work the drill one-handed in most any position.

Even with that advantage, don’t forget the fundamentals of driving screws:

- You can easily strip a screw head by not keeping the bit’s tip firmly engaged in the screw slot.

- Apply only light pressure until the screw is started, then press harder. Too much pressure will cause the driver bit to slip out of the screw slot and damage the workpiece.

- Don’t overdrive drywall screws; their heads snap off easily.