A 1-in. Belt Sander is a Versatile Sharpening Tool

Bit Gripper

Magnetic screwdriver bit holders sometimes leave the bit behind after you drive a screw. To make the bit stay put, wedge it tighter with a small scrap from a plastic bag.

Instant Tool Holder

Super-Simple Sharpener

New Uses for Old Glove Fingers

Lighted Screwdriver Hack

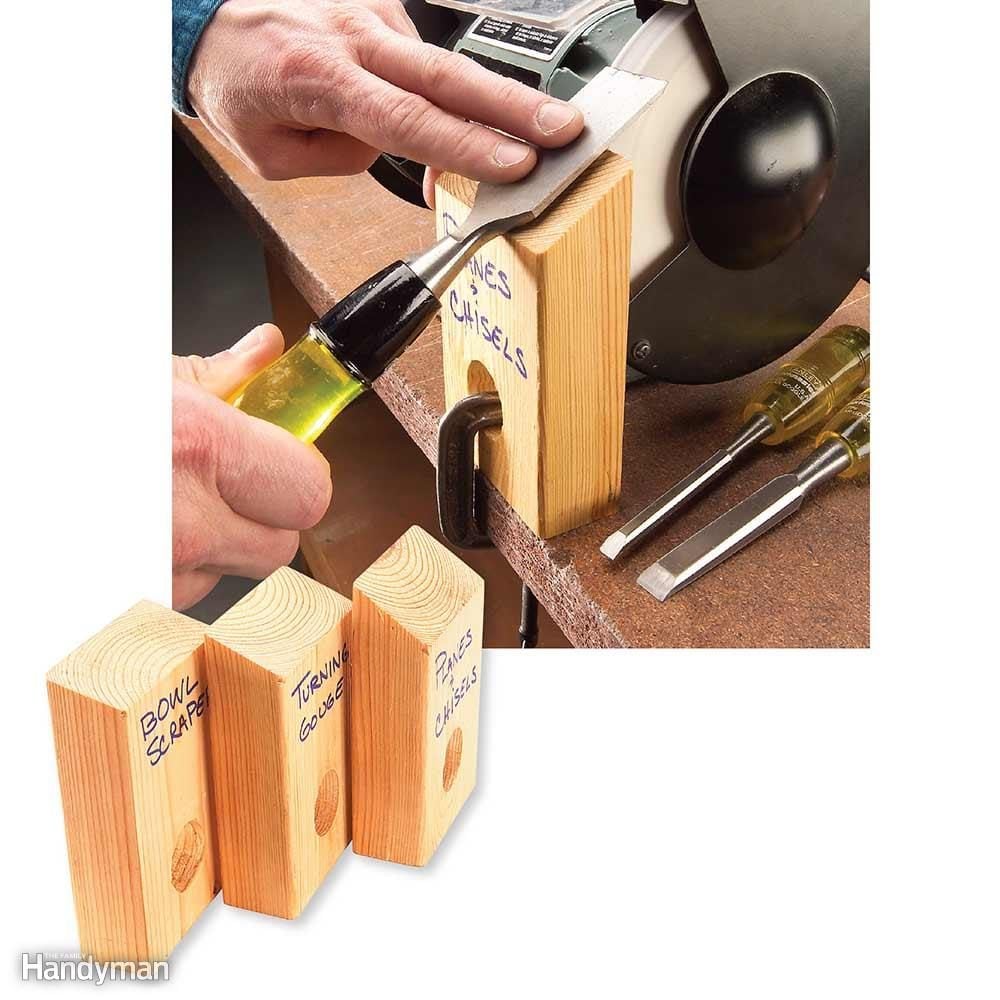

New Angles on Tool Sharpening

Here's a better way to hold tools securely while you're grinding them—and take the guesswork out of creating the right bevel angle. It's a short piece of 2x4 with an angled end and a 1-1/4-in. hole for a clamp. Make one for chisels and plane blades, and a few more with different angles for wood-turning tools. Large labels with the tool's name tell you which blocks are for which tools.

For a Delta grinder with a 6-in.-diameter wheel, a 5-1/2-in.-long piece of 2x4 aligns the tool to the wheel just right. For other grinders you may need to adjust this length. Note: The angle you cut on the block is not the same as the tool's bevel angle. But let's skip the math. To determine the block angle, turn off the grinder and hold the tool's bevel flush against the wheel. The angle of the tool shaft to the workbench is the angle to cut on the 2x4.

Easy-Grip Tool Handles

Best All-Purpose Hammer

Whether you're doing rough construction or fine finish work, the best all-around hammer is a smooth-faced 20-ounce with a straight claw. I use the claw to drive it under walls for lifting, to embed it in framing and even to do extremely crude chiseling. But best of all, it's a better shape for pulling nails than the curved claw style.

A Superior Handsaw

Mini Putty Knife

Is your putty knife too wide to fit into that little can of wood filler? Snip a 6-in. segment from an old hacksaw blade, grind the snipped end to resemble a low-angled chisel and then wrap the blade with electrical tape for a makeshift handle. You'll like how your homemade flexible knife spreads putty in a narrow path, minimizing cleanup. (And the built-in hanging hole is a nice feature.)

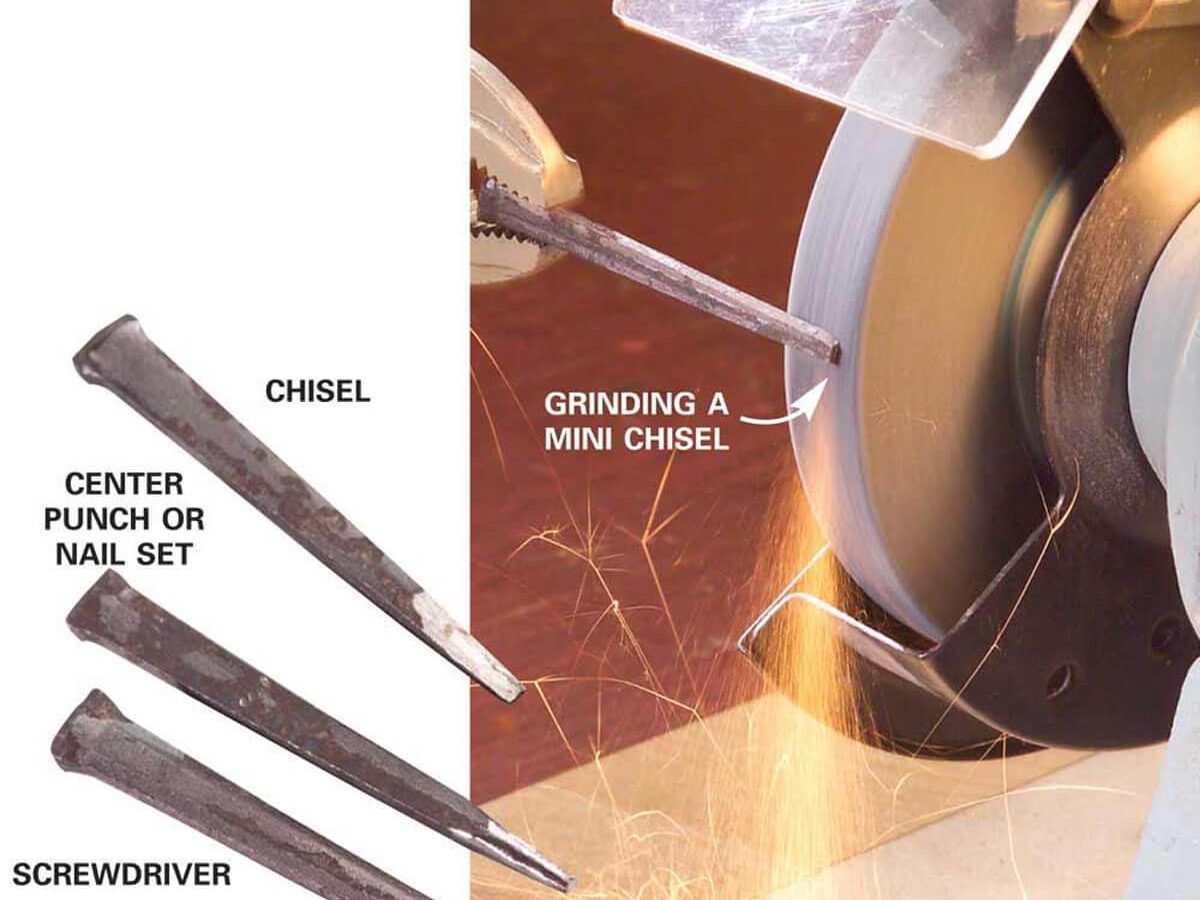

Mini Tools From Concrete Nails

How to Cut Conduit: Clamp Conduit for Easy Cutting

Foam Ball Tool Storage

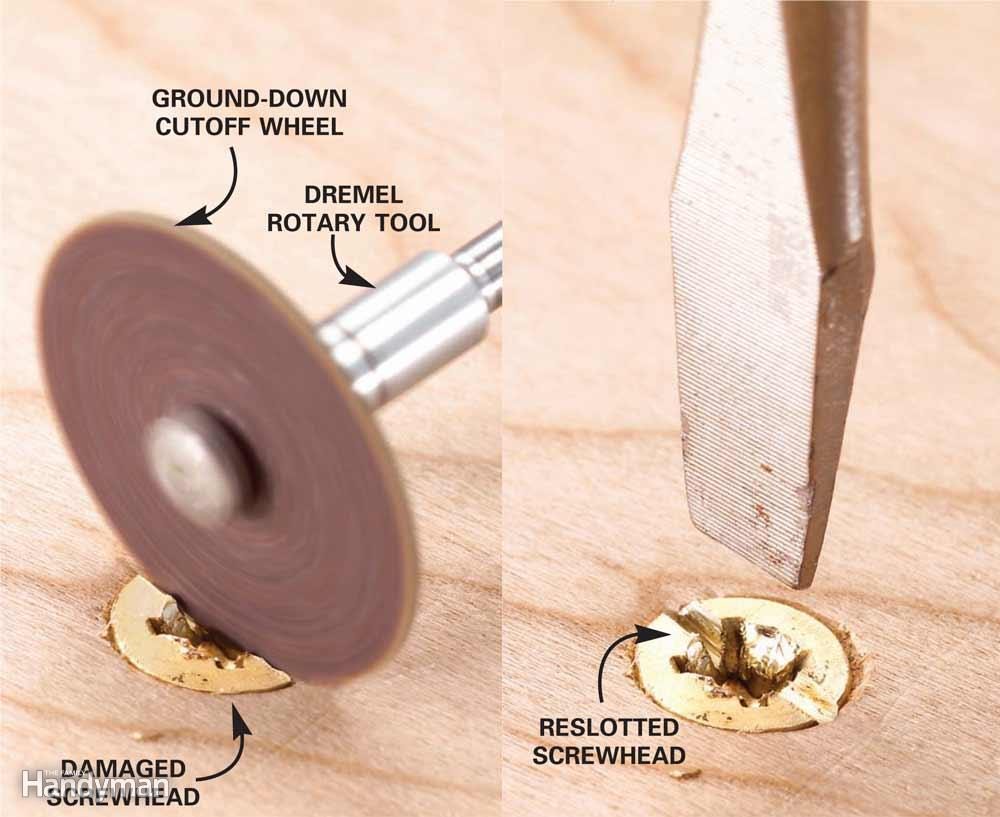

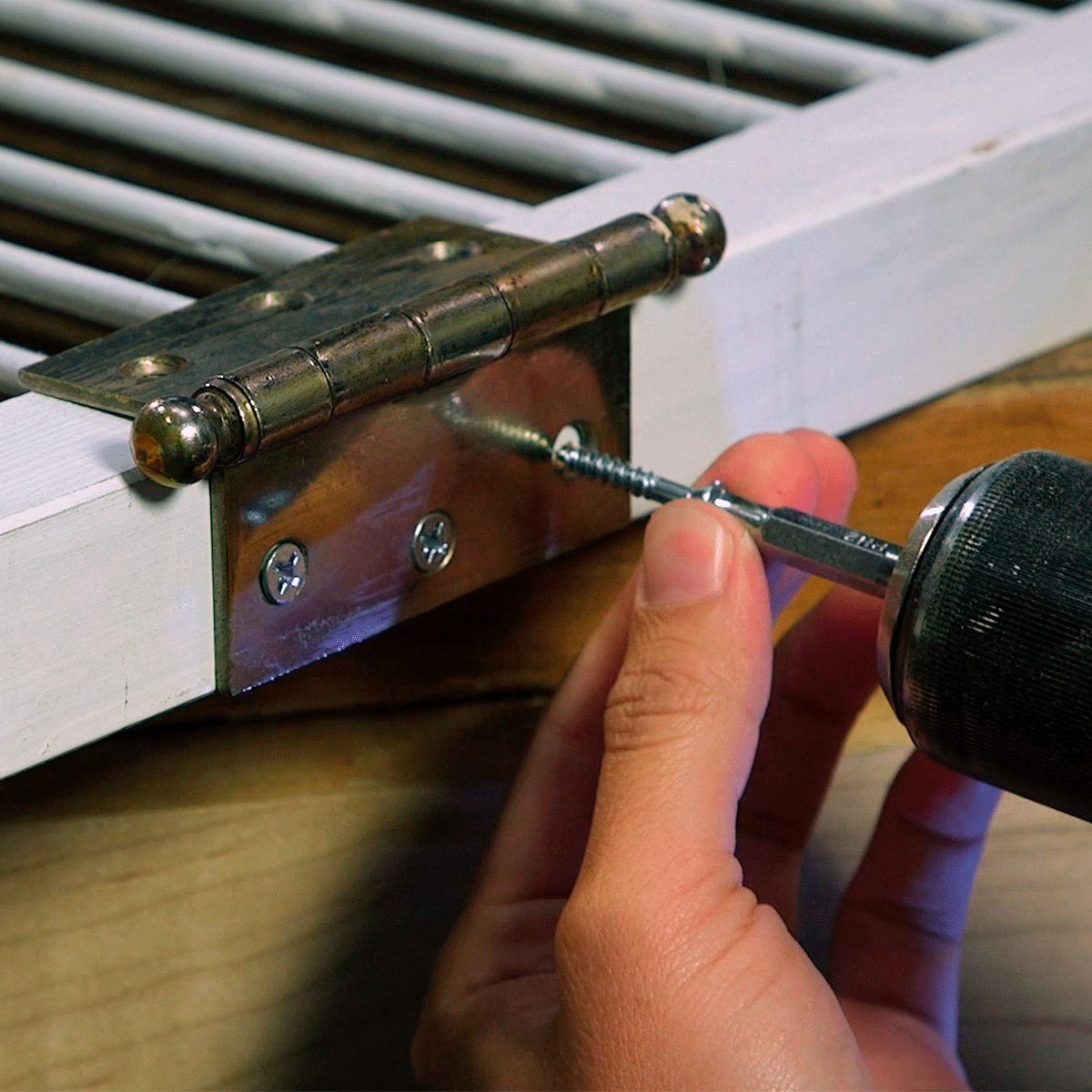

Screw Extraction

Try this tip for extracting screws with stripped heads. Mount a cut-off wheel in a Dremel rotary tool and grind the wheel against a piece of scrap metal to reduce the circumference. Make it small enough to cut into the screwhead without slicing into the wood surrounding the screw. Now grind a slot in the screwhead at an angle to the original slot, insert your screwdriver and gingerly unscrew that battered fastener.

Electrical Tools with Onboard Voltage Tester

PVC Tool Pockets

Portable Tool Kit

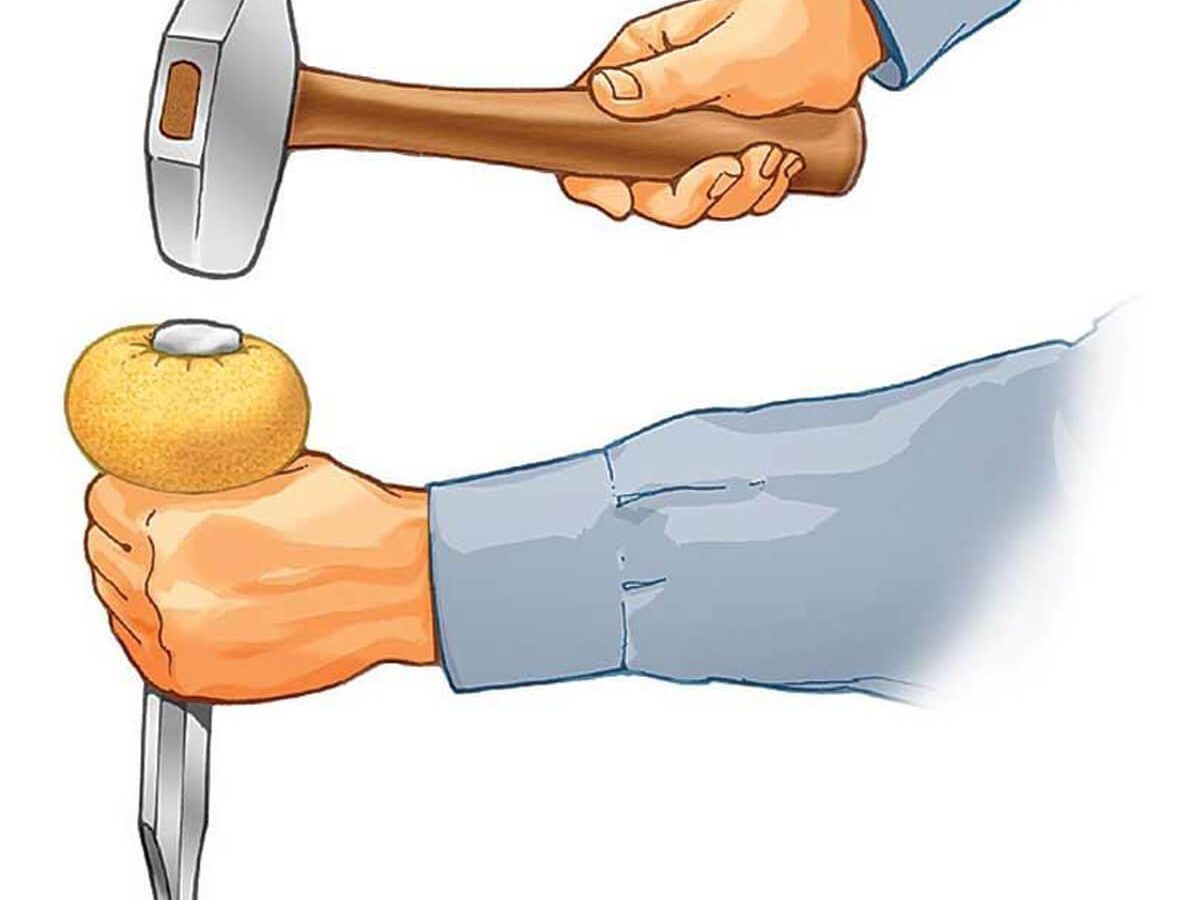

Foam Ball Hand Protector

Foolproof Chisel and Plane Sharpening

Long-Reach Screwdriver

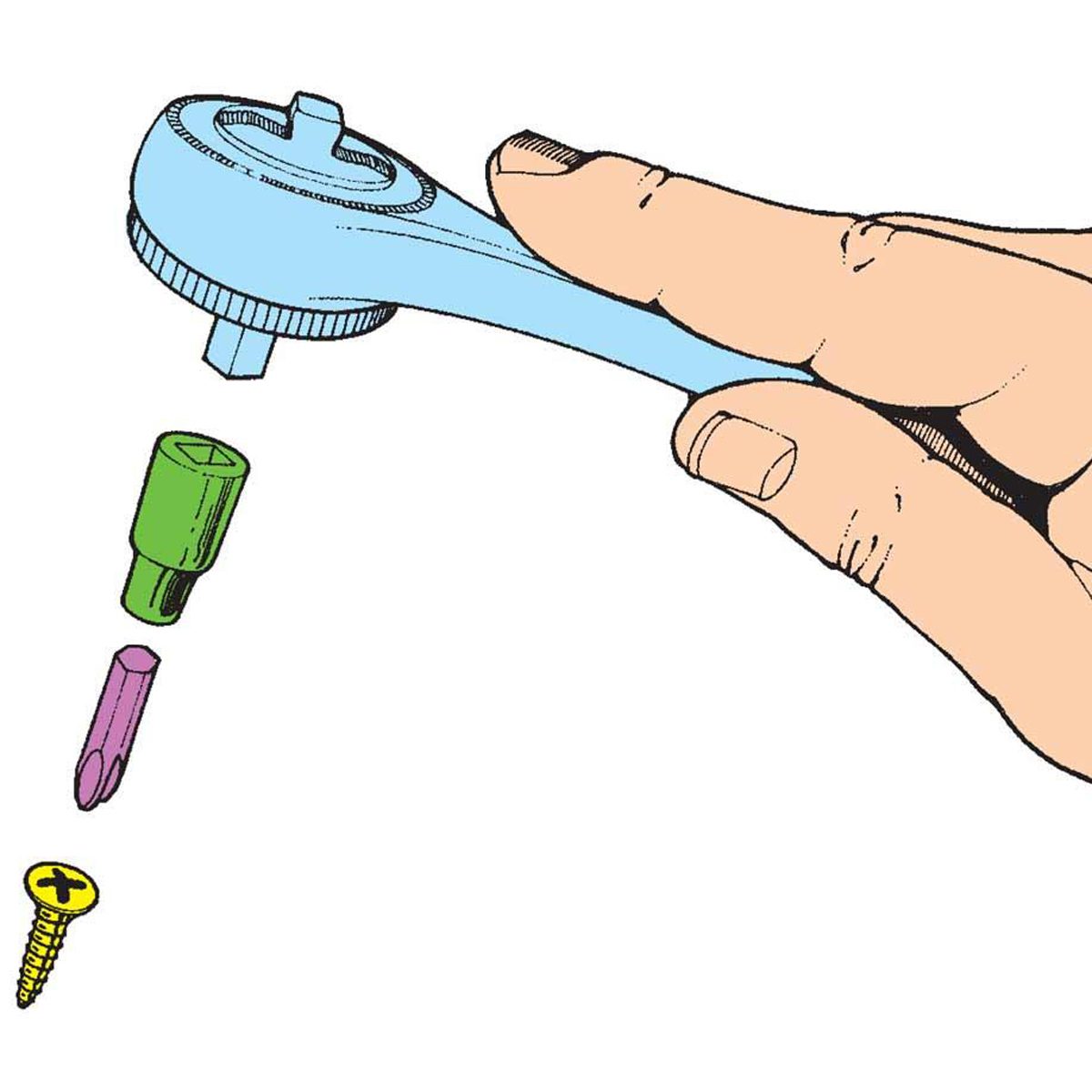

Perfect Junk Drawer Driver

Ratcheting screwdrivers make driving and removing screws by hand a breeze, and many come with an assortment of bits that store inside the handle for just about any type of screw head. Keep it in your kitchen junk drawer and you'll always know where it is.

Screw Loosener

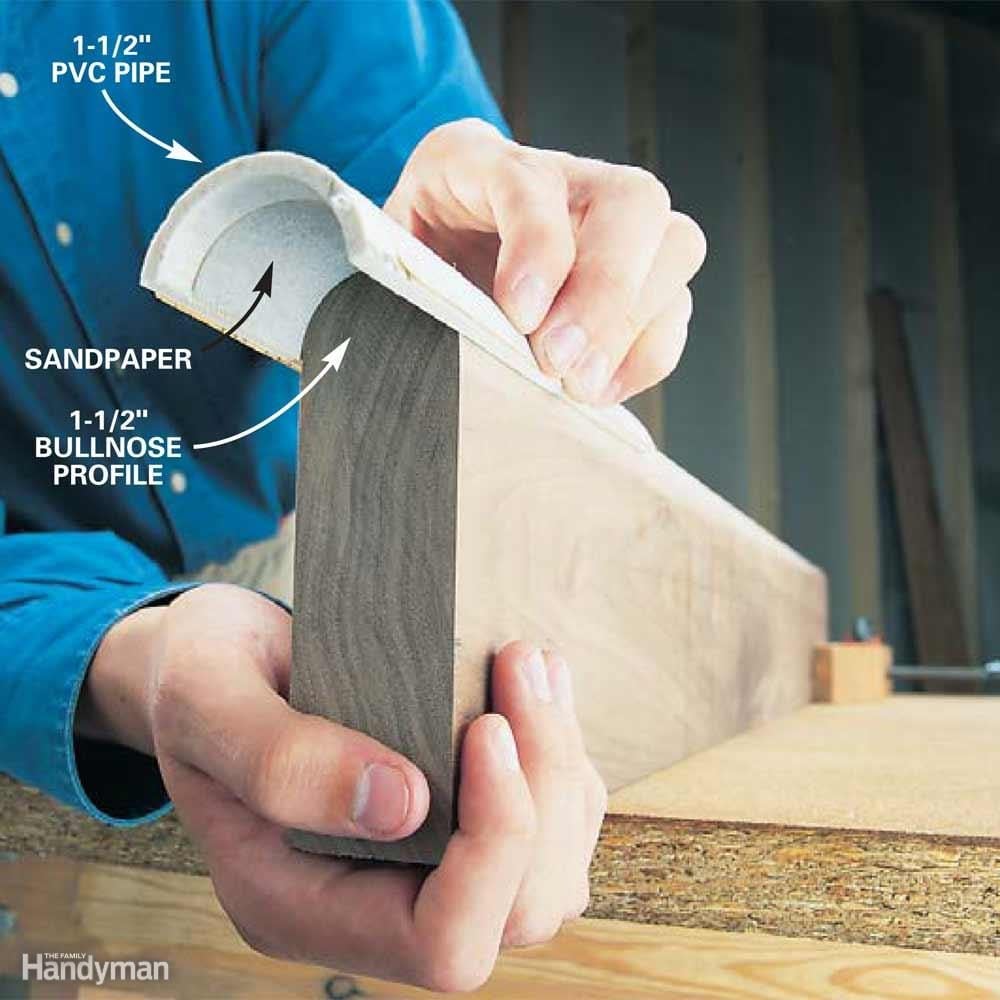

Curvy Sanders

Make contour sanders for convex and concave surfaces with short pieces of PVC pipe cut lengthwise. (It cuts easily with a handsaw, saber saw or band saw.) If you like, leave a section of the pipe uncut for a handle. Apply adhesive-backed sandpaper to the inner and outer diameters, or spray photo-mount adhesive on the pipe and apply regular sandpaper. You can match the PVC's inner and outer diameters to rounded or curved surfaces and edges so when you sand the contour, you'll preserve its original shape. Make a few PVC sanders in various diameters and you'll find yourself using them for all kinds of filing, sculpting and intricate fitting jobs.

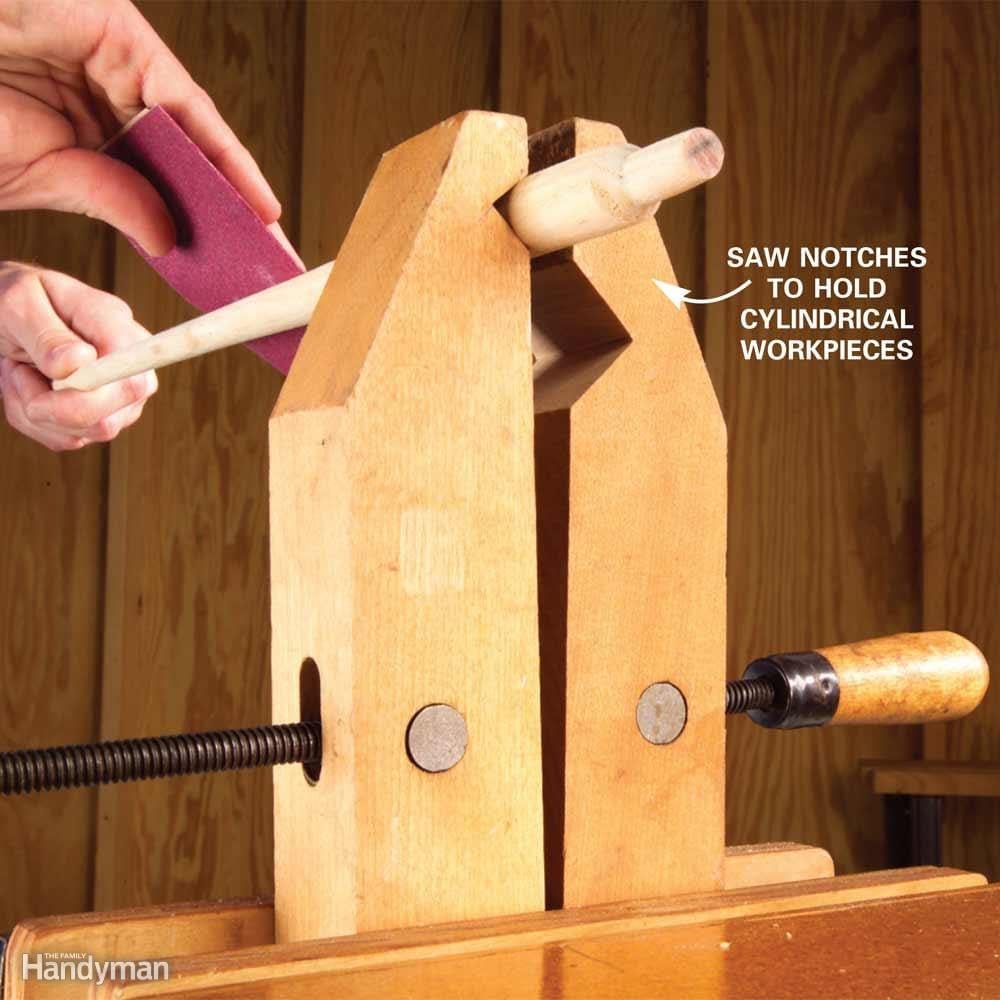

Notched-Jaw Hand-Screw Vise

Hand screws are ideal for holding cylindrical workpieces if you saw notches in the opposing jaws with your handsaw (one small notch for thin pipe or dowels and a second, larger one for big stuff). Now pieces won't slip or revolve as you carve, sand or saw. And don't worry; your notched hand screw will still work fine for regular clamping jobs.

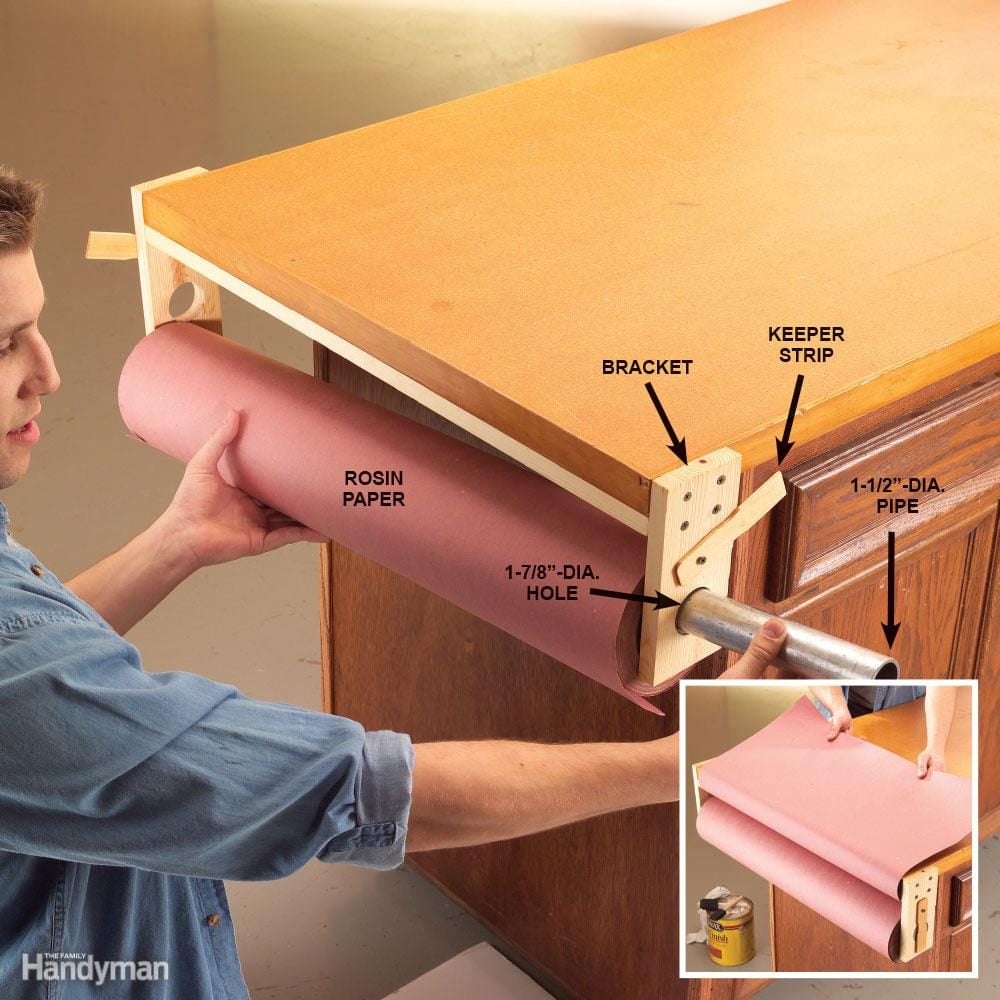

Rosin Paper Workbench Cover

How to Magnetize a Screwdriver

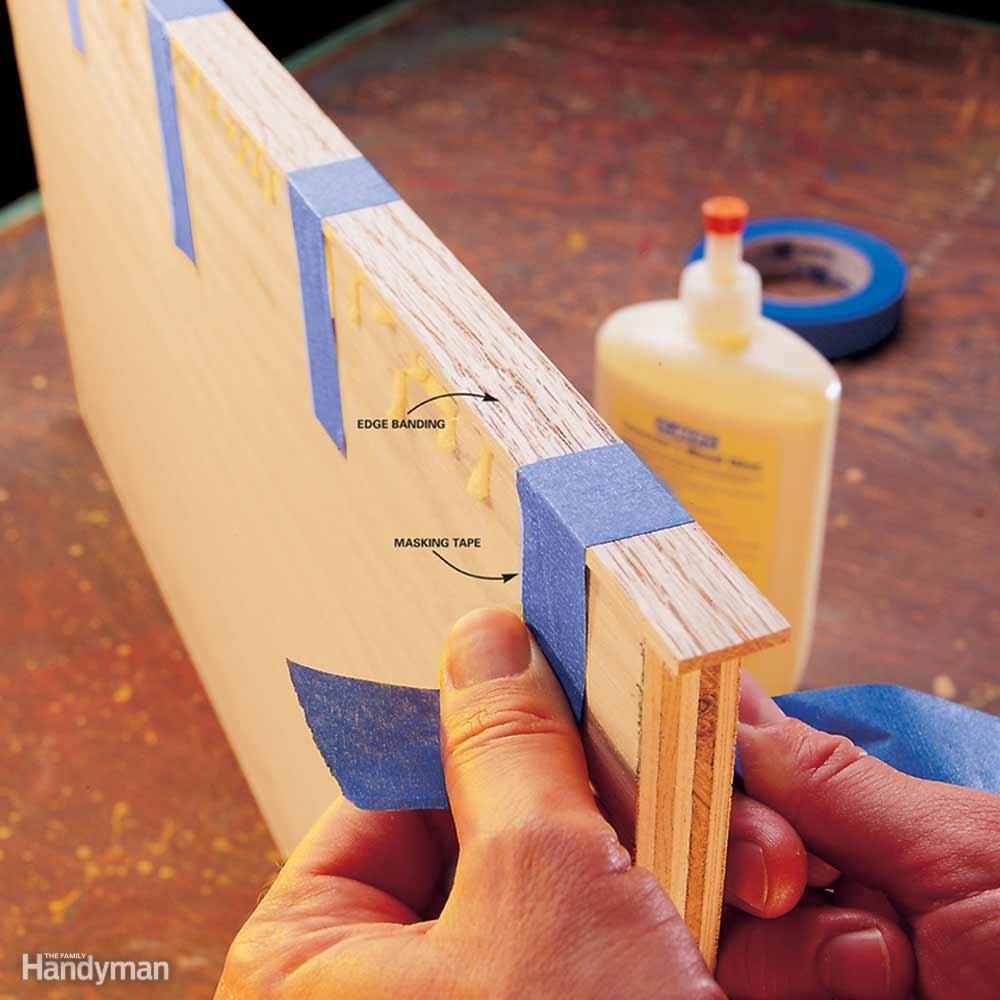

Edge-Banding Plywood

Socket Wrench Screwdriver

Kitty Litter Pouch for Tool Protection

Two Sizes of Brad Nails in One Gun

Caulk Gun Clamp

Hammer Cushion

A rubber chair leg cap instantly converts a hammer into a rubber mallet. And if you want to drive a nail without denting the surrounding wood, cut a hole in the rubber cap. Pound until the rubber strikes wood, then finish driving the nail with a nail set. A 1-1/8-in. rubber cap fits tightly over most hammers and costs about $1 at home centers and hardware stores.

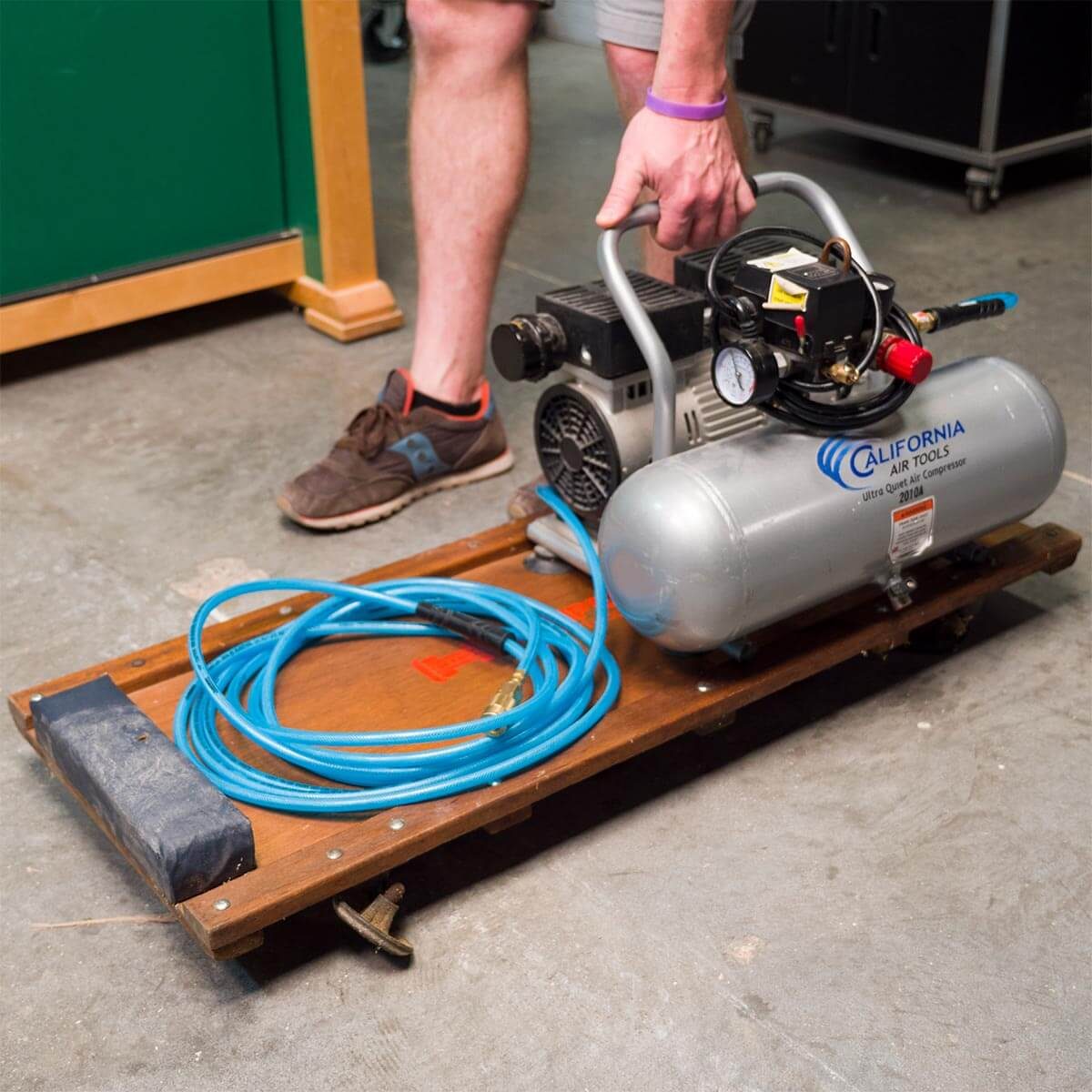

Compressor Creeper

Vise-Grips to Pull Nails

Customized Chuck Key

Long-Reach Screwdriver

Wrench for Rounded Bolts

Loosen bolts with worn, rounded heads with a pipe wrench! The pipe wrench jaws dig in and grab the head so you can remove the bolt. Check out these other clever new uses for your tools.