What to know about outside corner beads

There seems to be a lot of opinions and misinformation going around about outside corner beads. To help clear up any confusion, we spoke with several professional mudslingers and picked the brain of a USG Product Manager. What we found is that there really is no “best” or “worst” corner bead overall; each has their pros and cons. For many of the experienced pros we talked to it all came down to personal preference in the end. That said, some beads are definitely better suited for certain scenarios and different experience levels.

We are only discussing 90-degree corners in this story, but most of the information here applies to splayed (larger angled) beads as well as beads with decretive profiles. For more information on everything else having to do with drywall, click here.

Our test

To test the durability of each corner we slammed a 30-pound wood slab directly into them. Setting up the rig was simple, attaching the slab to a plywood base with a hinge so the distance from each corner would be the same. We did not have to push the slab forward because gravity alone was enough of a destructive force. All we did was hold the slab up, let it fall directly onto the corner bead, and then recorded the results.

Vinyl Corner Bead

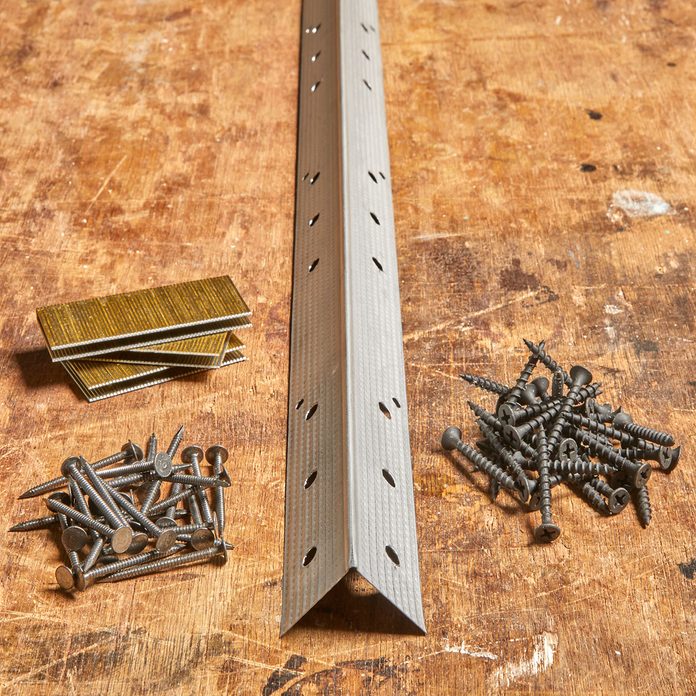

Below is a list of all the ways that vinyl corner beads can be attached to drywall. With each of these options below, you must use joint compound to fill and finish the bead. Tape is rarely, if ever, used over this kind of bead.

- Ready-Mixed joint Compound

- Trim Tex provides a water soluble adhesive that can be added to ready-mixed joint compound for attachment of vinyl bead

- Screws (most popular)

- Nails

- Staples

- Contact adhesive

Pros and cons of vinyl corner beads

Pros of vinyl corner beads

- Less expensive than paper-faced metal corner beads and paper-faced composite corner beads

- Durable during transportation and storage before installation

- Won’t rust, making it good for wet or high-humidity conditions

- The raised nose along the spine makes it easier to cover the bead with joint compound

Cons of vinyl corner beads

- Joint compound does not bond as well to plastic (and it may chip off if bumped)

- They are thicker—which means they are more difficult to cover and you will need to fan out further

- The bead is not as rigid as other varieties, so you must be careful to mount it straight during installation. If it isn’t straight it will be very difficult to finish

- If the wall isn’t straight, it will be much more difficult to make the edge straight

- Prone to cracking due to deep fill of joint compound and mechanical fasteners do not allow for building movement

Vinyl impact test results

This vinyl bead was installed with staples. There was no tape added. The results of the crash test were surprising, as we had heard from some pro-vinyl pros that they preferred vinyl because it wouldn’t dent. Surprisingly, that wasn’t the case here. The vinyl actually did dent, and the dent was bad enough that it would have had to be replaced if this were a real-life scenario.

Metal Corner Bead

Below is a list of all the ways that vinyl corner beads can be attached to drywall. With each of the options below, you must use joint compound to fill and finish the bead. Tape is rarely used over bead.

- Screws (most popular)

- Nails

- Staples

- Crimped (requires specialty tool)

- This method works best with metal bead with punch outs that will allow the metal to be crimped

Pros & Cons of Metal Corner Beads

Pros of Metal Corner Beads

- Least expensive option

- Strong (holds up to moderate abuse but will dent with heavy impact)

- Easy to install

- Provides a very straight edge, even on uneven walls

Cons of Metal Corner Beads

- Metal is very vulnerable to damage before installation and is difficult to protect during transport and storage

- Joint compound doesn’t bond as well to metal (may chip off when bumped)

- Could rust in wet environments like bathrooms as well as during pre-installation if stored in a wet area.

- Most dents will result in having to replace the whole bead

- Prone to cracking due to deep fill of joint compound and the fact that mechanical fasteners do not allow for building movement

Metal impact test results

This metal bead was installed with staples; no tape was added. As we expected, the impact created a large enough dent that that replacing the entire bead would be required.

Paper-Faced Metal Corner Bead

How it is installed:

- Ready-Mixed joint compound (applied by hand or with a corner bead hopper and corner roller)

- Nail (if necessary to straighten)

Pros & Cons of Paper Faced Metal Corner Bead

Pros

- Installed by the finisher/taper who has a vested interest that it is installed properly (Vinyl and metal are often installed by wallboard hanger who may not pay as close attention)

- Thin profile requires less joint compound to finish – less fan out

- Creates strong bond to surface using joint compound

- Paper makes it stronger so metal doesn’t bend as easily in storage or transport

- Rigid like regular steel bead

- Flexibility of paper and joint compound results in low cracking

- Corner roller creates a very straight edge and uniform attachment

- The raised nose along the spine makes it easier to cover with joint compound

Cons

- Most dents result in having to replace the whole bead

- May be more difficult for beginners to master

- More expensive than metal or vinyl options

Paper-Faced Metal Impact Test

This bead was installed with mud only. Similar to the regular metal bead, the result of the slab impact on this paper-faced metal bead resulted in a non-repairable dent. In addition to the dent, the paper started to pull away from the wall as well.

Paper-Faced Composite

Companies: CertainTeed No-Coat & Levelline, Straitflex

How it’s installed:

- Joint compound (Applied by hand or using a corner bead hopper and corner roller CertainTeed offers AutoSlam™ equipment for installation of roll bead products – faster application)

Paper-Faced Composite Pros & Cons

Pros

- More specialty profiles available for different applications (archways, niche, radius/flex, etc.)

- Most durable bead – resist dents

- Installed by the finisher/taper who has a vested interest that it is installed properly

- Won’t rust

- Available as sticks and rolls (Rolls are easier to store, transport)

- Rolls can be cut to size (less waste)

Cons

- Most expensive bead option

- May be more difficult for beginners

- Not as rigid – harder to achieve very straight edge

Paper-Faced Composite Impact Test

This bead was installed with mud only. This dent looks bad in the photo, but it was the only one that could have been repaired without replacing the entire bead. A little mud, and a fresh coat of paint could have covered up the damage. The paper-faced composite bead was the clear winner of our impact test.

Specialty Tools For Paper-Faced Beads

When pros install paper-faced beads, most speed up the process with specialty tools like this hopper and corner roller. When a bead is pushed through, the hopper applies the perfect amount of mud, quickly and efficiently. The roller presses the bead to the corner with smooth consistent pressure.

Specialty Profiles

Types: Bullnose, Chamfer, Santa Fe, reveal, niche, radius/flex, etc.

- Most options are in vinyl and composite

- Metal or paper-faced metal lends itself to Bullnose, because if there is a gap behind the bead, more rigid metal will not flex in if weight is applied following application.

Meet the expert

Guy Rosenthal has been a principal researcher at USG for 11 years where he specializes in tapes and finishing accessories. He is the Chair of ASTM Subcommittee C11.02 on Accessories for Gypsum Products. Before joining USG, he was a Product Development Project Manager at Illinois Tool Works for 10 years. He has a Ph.D. in Inorganic Chemistry from UC-Berkeley, a wife, 3 children, a large dog and a small cat.