Easy Shed Foundation

In most cases when building a foundation, the shed doesn’t have to rest on deep footings. A pair of trenches filled with gravel and topped with treated 6x6s is adequate in areas with well-drained soil. Level and square the 6x6s and you’re ready to build and attach the joist system.

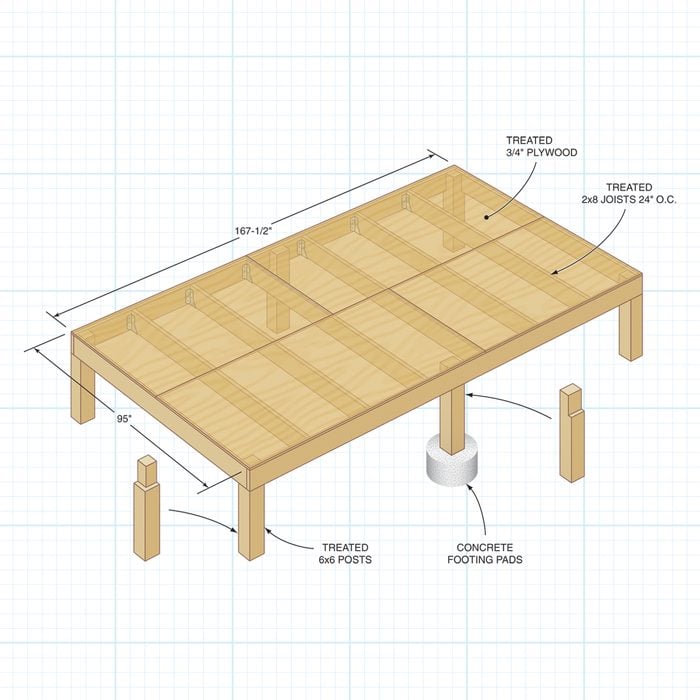

For Sloped Sites, Build on Posts

If your shed site slopes, pouring concrete is a bigger job because you must build strong forms and pour extra on the downhill side.

Here’s a simpler method: Build your shed floor like a deck, with footings, posts and a wood frame covered by plywood. If you don’t like the opening under the shed, build a skirt to cover the space between the shed floor and the ground.

Since locating buried utilities is free, it doesn’t make any sense to skip this step. Avoid an expensive mistake — or worse yet, a tragedy — by going online to call811.com for more information. Then call 811 a few days before you plan to dig to have your buried utilities marked.

Best Shed Floor is a Concrete Slab

For a shed floor that’s strong, long-lasting and low to the ground, it’s hard to beat concrete. Surprisingly, if you pour the slab yourself, the price is comparable to that of a wood platform. Just be sure to mix and pour it properly so it sets correctly.

Be Precise With Shed Floor and Walls

Don’t be tempted to get sloppy when you square up the floor and walls of your shed. An out-of-square start will haunt you through the rest of the project, from doors and windows to trim and roofing.

For a concrete slab, measure diagonally across the opposite corners of the form boards. Then adjust the forms until the diagonal measurements are equal. Do the same for a wood platform floor.

If you’re installing sheet siding on the walls, before you stand them up, measure diagonally and square up the wall before you nail on the siding.

Build Shed Roof Trusses

Whether you make your trusses or order them from the lumberyard, building a shed roof with trusses is much easier than framing a roof one rafter at a time. Generally, you’ll need one truss every two feet. Connect the framing for site-built trusses with plywood gussets glued and screwed to the joints. Next, check out these amazing backyard shed ideas.

Install Siding, Then Raise Shed Walls

It’s not always possible, but if you’re using 4- by 8-ft. sheet siding and have enough helpers around to lift the wall when you’re done, you can save time by siding the walls before you raise them.

Make sure to straighten the wall plates and square the wall by measuring diagonally before you nail on the siding. This is easier to do on a wood shed floor because you can tack the plates to the floor to hold the wall straight and square while you install the siding.

Keep Shed Framing Straight

A good carpenter constantly works to keep all the framing straight. And all it takes is some string.

Starting at the floor, stretch a string along the concrete forms or rim joist and make adjustments to straighten any deviations. Then do the same thing at the top of the walls, and finally when you set the roof trusses or ridge.

The trick for building a storage shed is stretching the line across a scrap of wood at each end so there’s a space between the line and the part you’re straightening.

On a wall, tack small scraps of 1/2-in. plywood at each end of the top plate and stretch a line tightly over the plywood. Then use a third scrap as a gauge to check the distance between the line and the lumber. Use braces or something similar to adjust the top plate until the gauge just fits. Now your top plate will be perfectly straight.

Choose Straight Studs

In a perfect world, all the studs would be straight. But since they aren’t, make sure to pick the best ones to use at the corners, door and window openings.

Sight down the length of the studs and set aside the ones that are perfectly straight. While you’re at it, also set aside studs that are really crooked. You can cut these up to use as cripples or blocking. You may find other uses for short pieces later on. Do you have a shed that needs to be relocated? Learn how to move a shed properly.

Dress Up a Plain Shed With Trim

Whether grooved or plain, installing 4- by 8-ft. sheets of siding is a fast and economical way to cover shed walls. But the result can look pretty plain. Adding wide corner boards, wide window and door casing, and maybe a horizontal band at the base and top can turn a utilitarian-looking shed into a masterpiece.

Build Trusses On the Shed Floor

If you’re building your own roof trusses, the handiest place to assemble them is right on the shed floor. But you have to do it before you build the walls.

Here’s the best method: Snap chalk lines on the floor to outline the truss parts. Then use the chalk lines as a guide for cutting the truss patterns and assembling the trusses.

Add Overhangs to Protect Shed Siding

Consider adding overhangs to the ends of your shed. They’re more work and require some extra material. But they’ll provide some protection from rain and snow, which translates to less painting and maintenance. Plus, overhangs just look better, and they give you a place to add decorative brackets. They’re well worth the extra effort.

Build Economical ‘Sandwich’ Doors

Frame-and-panel doors are expensive, especially if you want a distinctive style. But you can get the same look for a fraction of the cost by simply laminating two layers of inexpensive 3/4-in.-thick boards together.

For strength, plan to build the front and back layers so the corners overlap each other. Then, to accommodate inset panels, make the front pieces a little wider to create a lip for the panels to rest against. Use plywood or tongue-and-groove boards for the panels, and hold them in with stops nailed on the back.

You can assemble the two frames with pocket screws before gluing and screwing them together, but it’s not necessary. After the glue dries, plane or sand the edges to hide the layers.

Save Money With Barn Sash Windows

Utilitarian barn sash windows are perfect for sheds. Basically, you order the sash — the movable part with glass — and build a simple frame to hold it. Add a few hinges and hold-open hardware and you’ve got an inexpensive, nice-looking window. If you want a screen, you’ll have to build a separate frame and staple screening to it.

Order Cut-to-Length Steel Roof Panels

You can cut steel roofing panels with a circular saw and a carbide blade, but it’ll save you a lot of work if you order the panels the right length to start with. Plus, you’ll have a greater color selection if you order the roofing rather than buy off-the-shelf panels.

Remember to order in advance, though, since it usually takes several weeks for the roofing to arrive. And make sure the overhangs are the right size so the panels will slightly overhang the fascia.

Save Money on Shed Siding

If you plan to paint your shed, natural wood siding isn’t necessary. You can buy sheets of oriented strand board (OSB) siding at a fraction of the cost of real plywood, and it’ll probably last longer, too.

LP SmartSide panel is one brand. You can buy plain, grooved or stucco-like panels in several thicknesses and sizes. Ask at your local lumberyard to see what’s available.

Closet Door Hardware for Sliding Shed Doors

If you buy heavy galvanized hardware made for a farm building, it’s overkill. Buy heavy-duty closet door hardware instead.

It’s not really meant for outdoor use. But when protected by an overhang, it holds up well. And if the roller bearings get corroded, it’s simple to replace the entire hanger mechanism. Check out Johnson Hardware’s 111 track and 1025 ball-bearing hangers.

Rent Scaffolding for Shed Roof Construction

Working from ladders is more dangerous than working from scaffolding. Plus, constantly moving ladders around takes time.

When constructing the roof, consider renting a set of scaffolding with wheels. You’ll be amazed at how much easier it is to work from and set your tools and materials on a stable platform. You can rent a 5-ft.-tall section of scaffold with three planks and wheels for about $110 per week.

Add Brackets for a Custom Touch

Nothing dresses up a shed like brackets. They’re the ultimate low-effort, high-impact feature. In some cases, they also provide extra support for your gable-end overhang. Depending on the design, you can build brackets from 4x4s or by laminating 2-by boards.

Make a full-scale drawing to work out the details. Then build the brackets and attach them to the shed. Install the brackets tight to the underside of the overhang, then notch the fascia board to fit over them.

Here are a few tips for organizing your shed and finding the right place for all those hard-to-store items.

Avoid Painted Wood Trim

For painted trim, avoid real wood. Other materials hold paint better and won’t rot. Here are some products to consider:

- PVC: Azek is one brand. You can paint it or leave it unpainted— just don’t use dark colors. It can be shaped with a router-like wood.

- Fiber cement: James Hardie is one brand. This is less expensive than PVC, but you must take precautions to protect it from moisture.

- Engineered wood-fiber trim: MiraTEC is one brand.

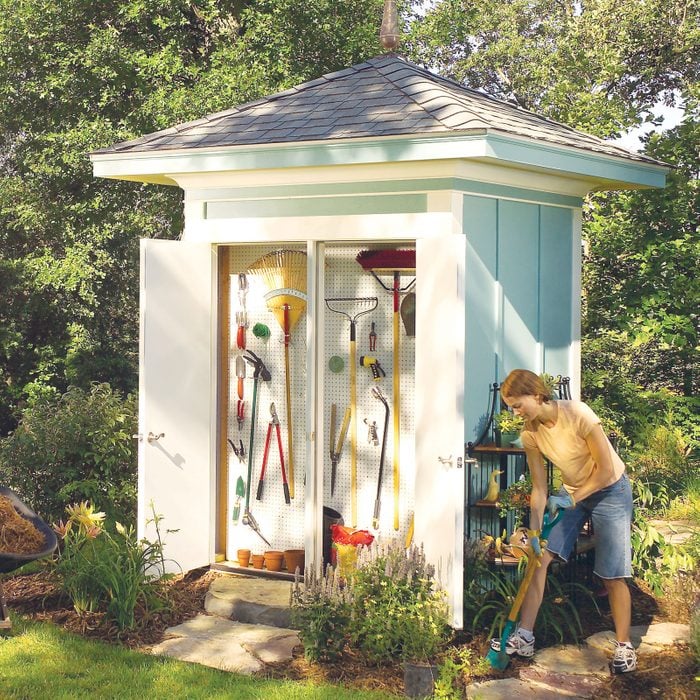

Easy Tool Access

A shallow tool locker on the side or back of a shed offers quick, easy access to lawn and garden gear.

To build this tool locker, we constructed an interior wall 12 inches from the back of the shed. Then we covered the studs with pegboard and installed a pair of steel prehung doors ($110 each) inside out so they swing outward. Homemade or sliding doors would work well too.

Inexpensive Skylights

Skylights let a flood of overhead light into a shed and, unlike windows, leave wall space free for hanging storage and shelving. Skylights made for houses are pricey, but there’s an inexpensive alternative.

Plastic dome skylights start at about $45 and are easy to install. Just cut a hole in the roof sheathing, nail the skylight into place and shingle around it. Plastic skylights aren’t exactly attractive, so place them on the side of the roof that’s least visible.

A Better Way to Trim

You don’t need to buy an expensive nailer for exterior trim. An inexpensive little 18-gauge brad nailer can do the job almost as fast.

Since those skinny brads don’t have enough holding power to keep large trim in place permanently, you need to first lay on a couple of generous beads of construction adhesive. Then tack the trim into place, using just enough brads to hold it while the adhesive hardens. Unlike thicker nails, brads rarely split the trim and you’ll have only a few tiny holes to fill.