How to Replace a Shutoff Valve

Updated: Feb. 27, 2024

Stop under-sink leaks with this 30 minute fix.

A full day

Intermediate

Less than $20

Introduction

You can spend time rebuilding the old valve, but the problems will just reappear years from now. The best way to deal with bad valves is replacing them with modern quarter-turn ball valves.

They rarely lock up, leak or wear out. Best of all, they take just an hour or so to install. Here's how to put them in.Tools Required

- Adjustable wrench

- Flame-protecting cloth gloves

- Locking pliers

- Soldering torch

Materials Required

- Shutoff valve

Identify the valve connection style

A shutoff valve connects to copper plumbing pipes in one of two ways:

- Compression fitting;

- Sweat fitting.

Identify the connection type used in your home by referring to the photos below.

If you have an older home with galvanized pipes, we suggest hiring a plumber to do the switch-out.

Unscrewing the old valve and screwing on a new one may seem easy enough. But if the pipe is rusted internally or the threads are rotted, this ‘simple’ plumbing job can turn into a plumbing nightmare. If your home is plumbed with PEX or plastic pipe, these instructions don’t apply.

Once you identify the connection type, buy a quarter-turn shutoff ball valve to match the size of the incoming copper pipe and the size of the supply tube connection.

If you’re replacing a sweat valve, you’ll need a torch, flux, solder, emery cloth, wire brushes and a flame protection cloth to shield the wall. This is also a good time to replace an old supply tube and a corroded escutcheon (wall trim plate).

Sorry to burst your bubble, but you need to stop believing these plumbing myths ASAP!

Project step-by-step (12)

Sweat valve

A sweat shutoff valve doesn’t have any hex flats where the copper tubing enters from the wall. Replace a sweat valve with another sweat valve or a compression valve.

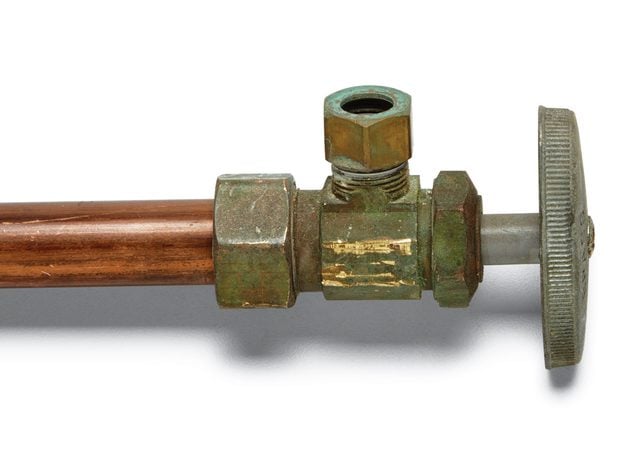

Compression valve

Examine the portion of the valve closest to the wall. Look for a hexagonal compression nut and matching hex flats on the body of the valve next to the compression nut. If the valve has a compression nut but no hex flats, look for two flats on the sides of the valve body.

Threaded valve

Look for threads and hex flats where the steel pipe enters the valve.

Prepare for valve replacement

Shut off the water at the main shutoff valve. If you have a gas water heater, turn the knob to the ‘pilot’ position. Shut off the circuit breakers to an electric water heater. Then open a faucet on the lowest level of your house and another faucet on an upper level to drain the pipes.

Disconnect the supply tube from the shutoff valve. Replace the valve.

After replacement

Close the new valve. Open the water-main shutoff valve and let the water run until all the air is out of the pipes. Then shut off the upper and lower faucets.

Check the new valves for leaks. Turn the water heater gas valve back to ‘on,’ or flip on the circuit breakers to the electric water heater.

Remove the old sweat valve

Hold the valve with a pliers, loosen the packing nut and unscrew the entire valve stem. Peek inside and remove the old washer if it’s stuck on the seat. Removing the valve stem allows any remaining water to drain out, making the unsweating process easier.

Before you do any torch work, make sure there’s a fire extinguisher nearby and safeguard the wall with a flame protection cloth. Then remove the old valve and the remaining solder.

To begin, drape the flame protection cloth over the copper tubing and tape it to the wall. Adjust the torch to a small fame and aim it toward the body of the valve. As soon as the solder melts, twist and pull the valve off the copper tubing with a pliers.

Clean excess solder

Clean the tubing with emery cloth. If you’re replacing a sweat valve with a compression valve, sand off all traces of solder before adding the new escutcheon, nut and sleeve. Otherwise, remove enough old solder to allow the new sweat valve to slide onto the tubing.

Remove the stem and wire-brush the opening in the new quarter-turn valve and apply flux to the valve and the copper tubing.

Put on a leather glove and grab a damp cotton rag (microfiber cloth will melt). With the flame protection cloth in place, heat the valve just enough to draw in the solder. Heat the remaining solder with the torch until it’s molten. As soon as the solder melts, wipe away the excess solder with a damp rag.

Be sure to wear leather gloves to prevent steam burns.

Remove and replace a compression shutoff valve

To remove a compression-style valve, hold the valve body with an adjustable or open-end wrench, or a slip-joint pliers. Grab the compression nut with another wrench and turn it clockwise to loosen it. Then pull the valve off the copper tubing.

Next, remove the old compression sleeve and nut. Grab the old sleeve with a pliers, using minimal pressure to avoid distorting the copper tubing. Then rotate and pull it off the tubing. If the sleeve is stuck, saw it and break it.

To saw it off, use a hacksaw to cut partially through the sleeve at an angle. Use short strokes to avoid cutting into the copper tubing. Check your progress and stop cutting before you reach the copper.

Twist and break the sleeve

Insert a flat-blade screwdriver into the cut and twist the screwdriver to break the sleeve. Slide off the old sleeve, old compression nut and the escutcheon (if you’re going to replace it).

Position the new compression sleeve

Slide the new escutcheon and compression nut onto the copper tubing. Then slide the new compression sleeve onto the copper tubing. If the old sleeve left depression marks, locate the new sleeve slightly forward of the marks.

New compression valve

Insert the new valve and apply a very light coating of pipe dope to the compression sleeve. Next, screw the compression nut onto the valve until snug. Hold the valve with a wrench or a pliers and tighten the nut a one-half to three-quarters turn (follow the manufacturer’s tightening instructions). Connect the supply tube and test for leaks.

Can you use a push-fit valve?

Several companies make quarter-turn push-fit ball-style shutoff valves that install without tools. They’re a good alternative to sweat and compression fittings if you have enough tubing projecting out from the wall and if that tubing is in good shape. They make the job even simpler.

If your stub-out tubing is perfectly symmetrical and long enough and features a square-cut end, you might use a push-fit valve to replace your old compression or sweat valve.

Most push-fit valves require at least one inch of stub-out tubing. So measure the length of the stub-out and refer to the valve manufacturer’s length requirements before buying.

If your tubing will work, shop for a valve that meets your configuration needs (straight or angled). Push-fit valves are available with and without a permanently mounted supply tube. We don’t recommend the permanently installed supply tube version because you have to shut off the water and replace the entire unit if the supply tube ever needs replacement.

Before installing a push-fit valve, remove any burrs from the open end. If you’re replacing a sweat valve, remove all traces of solder and ensure the tubing is perfectly round. Then mark the installed length on the tubing and push the valve onto the tubing until it reaches the mark.

Next time you have a drip, clog or leak, don’t shell out big bucks for a professional plumber. You can fix it yourself with these tips for becoming a master plumber!