How to Build a DIY Raised Patio Planter With Legs

Updated: Jan. 23, 2024

Our planter is tops for easy construction, sturdiness and convenience. Plus, the curves and trim make it a pretty addition to your deck or patio. You'll get about 8 sq. ft. of planting area.

A full day

Beginner

$101–250

Introduction

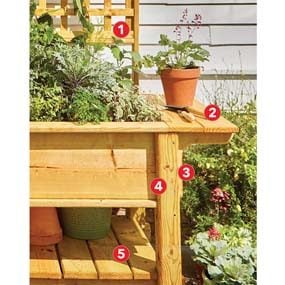

This sturdy, easy-to-build raised mini garden gives you about 8 square feet of planting area.There are a lot of things we love about this raised planter box, including that it has legs so that gardeners can stand as they tend to their plants. We also appreciate these features:

- The optional trellis supports climbing plants like tomatoes and peas.

- Side tables are convenient work surfaces and handles when you need to move the planter.

- Boards protrude at ends or corners. Those ‘reveals’ hide mistakes. If your measurements or cuts are a little off, no one will notice.

- Notched joinery is super sturdy and easy enough for a beginner.

- Lower shelf provides about 8 sq. ft. of storage space.

All of the materials are available at any home center. The legs and planter box are made from treated dimensional lumber. The extension tables, bottom shelf and trim boards are made from what’s commonly known as “5/4 decking material” or just “deck boards.”

Take note: Treated lumber is more variable in width and thickness than standard dimensional lumber. We found 2x12s ranging from 11-1/8 in. to 11-3/4 in. wide at our home center. And we found two types and thicknesses of treated decking material: The premium stuff was almost 1-1/4 in. thick while the standard was barely 1 in. Keep this in mind as you build and adjust your measurements accordingly.

Project step-by-step (11)

Cut the Lower Leg Notches

- Cut the four legs (A) to length.

- Mark the positions of the upper and lower notches.

- Set your saw depth to 1-1/4 in., then make a series of cuts no more than 1/2 in. apart.

- Drive a chisel into the cuts and pry; the little fingers will shear off.

- Flatten the remaining nubs with a chisel.

- Grab a 2×4 scrap and make sure it fits into the notch.

Cut the Upper Leg Notches

- Set your saw depth to 2 in. and make a series of cuts near the end of the notch (to create a square bottom).

- Break out the fingers as shown above.

- To complete the notch, make the long cut.

- Pro tip: Your saw won’t cut completely through the leg, so you’ll have to flip the leg over and cut from the other side.

- Note: Your notches should be as long as your 2x4s and 2x12s are wide.

Mark the Shelf Supports

- Cut the long box sides (B) to length.

- Use a square, a paint can and a washer to mark the shelf supports.

- Make the straight cuts with a circular saw and the curves with a jigsaw.

- Soften the cut edges with sandpaper or a router and round-over bit.

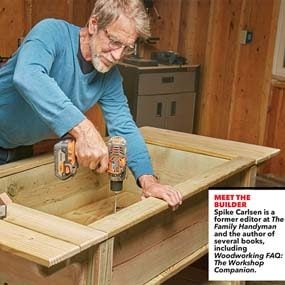

Assemble the Box

- Join the sides to the ends with 3-in. exterior screws.

- Drill pilot holes and drive the screws until the heads are slightly sunk into the wood.

- Note: You can cover the heads with exterior wood filler or leave them exposed.

Add the Legs

- Mark the leg locations 1 in. from the ends of the sides using a framing square.

- Position the legs and fasten them to the box side with 3-in. screws.

Install the Rungs and Supports

- Flip the planter upside down and install the bottom support boards.

- Place the rungs in the leg notches and secure them with 3-in. screws.

- Position the bottom supports (E, F) so they extend about 5/8 in. inside the box and screw them in place.

- Note: The overhang should be the same on both sides.

Install the Shelf Slats and Bottom

- Position the planter upright and install the slats for the bottom shelves.

- Space them about 1/4 in. apart and notch the corners of the outer slats as needed.

- Drill three or four 1-in. drainage holes about 1/2 in. up from the bottom of each end board.

- Plop the 3/4-in. plywood bottom into place and secure it with a few 1-1/4-in. screws.

- Space the shelf slats (G) evenly and screw them into place.

- Notch the end slats to fit around the legs.

- Then install the planter bottom.

Build the Lattice Panel Trellis (Optional)

- Begin by ripping a 5/4×6 x 10-ft. board in two.

- Construct the panel frame (L, M, N).

- Rip 5/4 x 5/4 stops (P, Q) out of scrap material and secure them to the frame.

- Cut the lattice to size, set it into the frame and nail it to the stops using 3d nails.

- Secure the lattice panel to the back by driving screws through the panel legs into the planter box.

Cap Off the Planter

- Screw shelf boards to the shelf supports.

- Note: The inner ones should extend just a little past the inside edge of the box.

- Install the side trim, letting those edges extend slightly inward, too.

Finish the Planter

- Apply a coat of exterior stain to the planter, or leave the wood natural and let it mellow to a soft gray.

- To prevent soil from seeping out the drainage holes, line the bottom of the planter box with landscape fabric, letting it extend a few inches up each side.

- Fill the planter with soil or other growing medium and get digging.