Label Your Face Frame Parts First

The first step to kitchen cabinet construction might seem boring but it’s crucial. Dry-fit the face frame parts first so the best side of all the boards will be seen. This helps you to avoid stark grain color variations at joints. Next label all the pieces with a pencil. That way, you can put the frame back together the same way you laid it out. The pencil marks are also a useful guide when you’re ready to sand the assembled frame in your kitchen cabinet plans. If the marks have disappeared, you’ve probably sanded the joints flat.

Build the Cabinets, Buy the Doors

Building kitchen cabinet doors is doable but can be tricky. It sometimes requires powerful and expensive wood-shaping equipment. And if you have a bunch to build, you’ll need a lot of clamps and even more space. Unless you have unlimited free time, consider building your cabinets but buying your doors. You’ll find many door makers online (search for “buy cabinet doors”). Cabinet doors can be ordered in a variety of styles and in increments as small as 1/16 in. It’s always nice to be able to see and touch, so check out your local cabinet shop as well. Next, get to know these kitchen cabinet installation tips.

Assemble the Face Frame with Pocket Screws

Pocket hole screws are a fast and easy way to join a face frame. You don’t need a lot of clamps or wood glue. A mortise-and-tenon joint may make you feel like a true craftsman, but only you will know you spent all that extra time on this kitchen cabinet construction project. You can buy an entry-level pocket screw jig for less than $50, but if you plan to build several face frame projects, spend about three times that to get a top-of-the-line jig.

Leave off the Back Until You Apply the Finish

If you plan to paint a finish on your kitchen cabinet construction project before you install it, leave the back off until after you’ve applied the finish. It makes getting into all those nooks and crannies a lot easier, especially in deeper cabinets. Wood glue won’t stick to finishes, so if you want to glue on the back, use polyurethane glue.

Trim Some Face Frames Flush

Face frames on furniture look best when they’re flush with the cabinet sides. But it’s still better to build the face frame a little bigger (about 1/16 in.), and trim it off with a flush trim router bit. Adjust the bit depth so the cutting edges are only slightly deeper than the face frame.

A self-piloting flush trim bit with a bottom bearing makes the joint between the face frame and box almost disappear. They are available anywhere router bits are sold.

Gang Up Your Components While Cutting, Planing and Sanding

Even with a good table saw, it’s difficult to exactly replicate previous cuts, so plan ahead and cut all your face frame parts at the same time. Gang-planing your stiles and rails will save time and ensure all the parts are exactly the same width and thickness. Gang-sand board edges by clamping them together. That not only speeds up sanding but also keeps you from rounding over edges. And always make more parts than you need. Having extra allows you to choose the best boards.

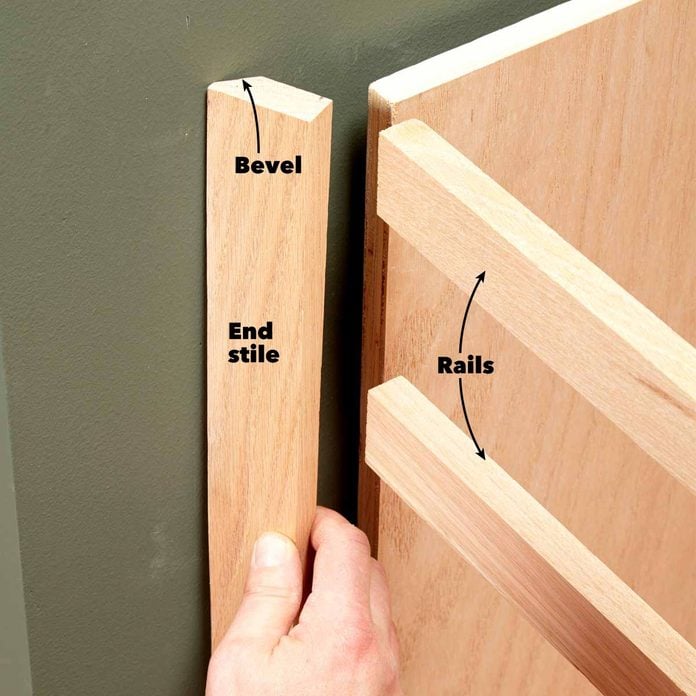

Leave the End Stile Off to Scribe

Leave one end stile off when you install cabinets that butt against walls at both ends. With a complete face frame, you won’t be able to push the cabinet into place or scribe and adjust the stile to fit. Cut that last stile a bit oversize to leave room for scribing, and rip a 45-degree back bevel for easier planing to your scribed line. The bevel also makes it easier to twist the stile into place.

Nail the Face Frame to the Boxes

One of the easiest ways to attach face frames to carcasses is with a thin bead of wood glue and an 18-gauge brad nailer with 2-in. brads. Be sparing with brads; their main duty is to hold the frame in place while the glue dries. A couple per side and wherever there’s a void should do the trick. A little putty will make the brad holes almost invisible.

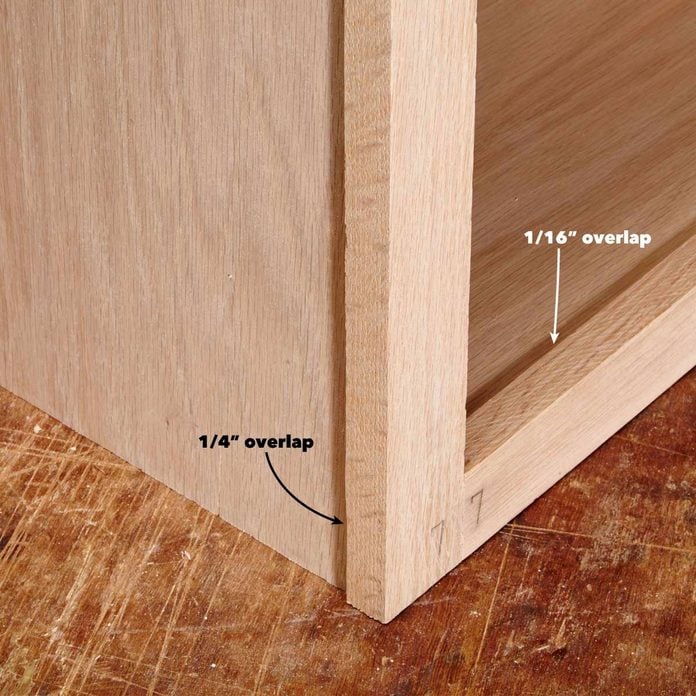

Build Face Frames Larger

A main function of a face frame is to hide the exposed plywood laminations. A face frame does a better job of this if it overlaps the box edges a bit. Making the face frame run past all the plywood edges provides a little wiggle room and hides not-so-perfect saw cuts on the plywood. Face frames on the sides of kitchen cabinets should overlap 1/4 in. on the outside edge. This makes room for adjustments when installing them next to one another. Build the face frame so that the bottom rail (“rails” are horizontal boards and “stiles” are vertical boards) projects 1/16 in. above the bottom shelf of the cabinet.

Don’t Cut Rabbets if They’re Not Needed

It’s common practice to cut a rabbet (a notch to receive the 1/4-in. back panel) on the back edge of cabinet carcasses so the back panel will be recessed. But that’s not necessary if the cabinet sides won’t be visible—the back panel edges won’t be either. Save yourself some time and just tack on the back panel with a brad nailer. Make sure to take into account the overall depth of your cabinets—they’ll be 1/4 in. deeper if you go this route.

Don’t Settle For What’s in the Home Center

Home centers and lumberyards typically have only a few cabinet-grade plywood options in stock, but almost all of them can order what you need. Whatever your wood preference, they can most likely accommodate you. It takes a little planning ahead, but don’t limit yourself to oak if you really want cherry. These are your kitchen cabinets, and you should take the time to get materials that you’ll love for years.

Build a Separate Base

It’s important to use dead-straight wood for bases so it’ll be flat for setting the cabinets. Once your cabinets are installed, finish off the base front with a strip of 1/4-in. plywood that matches the cabinets.

Most factory-built cabinets have a recessed “toe-kick” that’s typically about 4 in. high and deep. But you can also make a separate base that’s the total length of the cabinet assembly and build shorter cabinets to make up the difference. With this method, you won’t have to mess around with figuring out and cutting toe-kick profiles on your cabinets.

This is also a handy technique when you have an uneven floor because you need to level and shim only one base instead of several individual cabinets.

Build Individual Boxes for Easier Installation

Moving and installing long one-piece cabinets can be a tough job, and it may not even be possible to get the assembly into the room. Instead of creating such a monster, build individual cabinet carcasses. Add the face frame after they’re all in place.

Cap End Cabinets to Hide Fasteners

If you cap the end cabinet with 1/4-in. plywood, you don’t have to hide the fasteners you used to build your boxes. That means you can use large, sturdy screws without worrying about ugly putty-filled holes. You’ll also need an end cap if you choose to build a separate base. Use construction adhesive and a few small brads to fasten the panel in place, and make sure you extend the outside face frame stile an additional 1/4 in. to account for the thickness of the plywood.