Easier Paver Patios

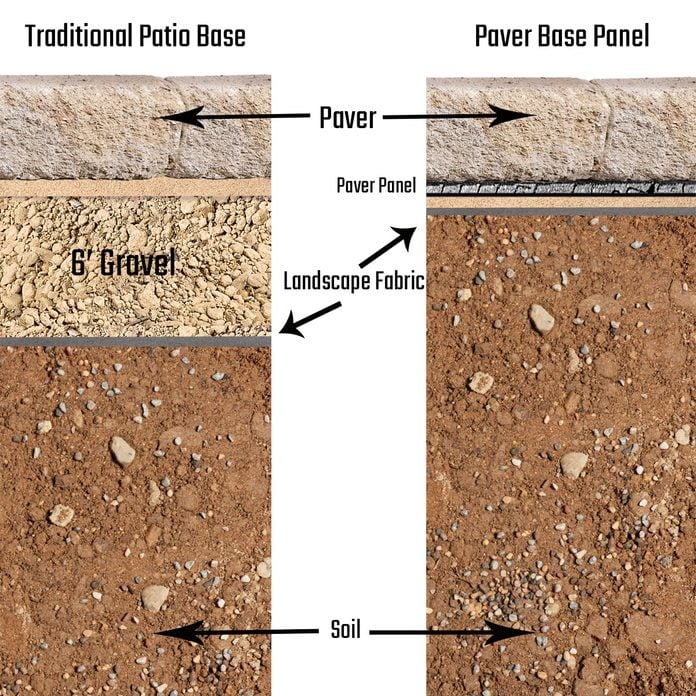

A traditional base for a paver or stone patio is a 6-in.-deep layer of compacted gravel. For a typical 10 x 12-ft. patio, that means carting away about 2-1/2 tons of soil, and hauling in the same amount of gravel. But there’s an easier way. Let plastic panels take the place of the gravel base. For that same patio, you would need only 24 paver base panels weighing a total of about 30 lbs. to replace the 2-1/2 tons of gravel.

So how does it work?

Paver base panels are made from lightweight high-density polypropylene. The panels typically have tongue-and-groove or shiplap edges to keep the panel edges flush with one another.

You may wonder how a thin plastic mat can effectively replace a 6-in.-deep layer of compacted gravel. The answer is that the panels spread out the load, so the weight of a person walking on the patio is distributed more widely. Distributing the load puts less pressure on the soil and prevents the paver bricks from becoming uneven.

The panels have the added advantage of providing an insulating layer that reduces problems caused by soil that thaws and refreezes. And finally, paver base panels have built-in channels and holes to drain water to the sand layer below.

Paver base products have been around for only a few years, so it’s uncertain how they’ll perform long-term. But results are good so far. Studies from independent engineers have concluded that the panels are equivalent to a compacted gravel base for load distribution and superior for

thermal resistance.

Benefits of a Panel Base

- Requires less digging.

- Eliminates heavy gravel fill.

- Saves time.

- Reduces the cost of digging and hauling.

- Prevents damage to the landscaping caused by excavating equipment.

- Allows patio installations in fenced areas or areas with limited access.

- Protects the screeded sand while you’re installing pavers.

Building with paver base panels

Paver base panels don’t eliminate the need for careful site preparation. You’ll have to remove grass or other vegetation and skim off 2 to 4 in. of soil. You also must remove soil evenly, leaving a flat surface because there’s no thick layer of gravel to make up for uneven ground. After digging and grading, there shouldn’t be more than about 1/2-in. variation in flatness over the area.

Since there is no gravel base, it’s important to use a plate compactor to tamp down the soil before covering it with landscape fabric and a layer of sand. The sand layer must be screeded to provide a flat, properly sloped surface for the paver base panels. Lay the paver base panels over the sand bed. The lightweight, easy-to-cut panels make this a quick task. Follow the manufacturer’s instructions for offsetting the panels and for edge details. If you’re planning to install stones that vary in thickness, you’ll have to put a layer of sand over the panels to allow leveling of the stones.

Five things you’ll need: #1

Landscape fabric

The purpose of the landscape fabric is to prevent the sand from mixing in with the soil. But it’s important to use a nonwoven fabric. Woven landscape fabric isn’t very permeable and can act like a swimming pool liner, trapping water under your patio. Also look for fabric with at least a 20-year life span.

Five things you’ll need: #2

Sand

You’ll need a layer of sand that’s an average depth of 3/4 in. Buy all-purpose or fill sand, not sandbox sand. It’s too fine. If you’re buying bags of sand, figure about one 50-lb. bag for every 8 sq. ft. of patio.

Five things you’ll need: #3

Paver panels

Divide the square footage of your patio by the square-foot coverage of each panel to determine the number of panels you’ll need. Add about 20 percent if your patio is an irregular shape.

Five things you’ll need: #4

Paver edging

You’ll need a way to hold the paver bricks in place along the edges of the patio. The most common and convenient method is to stake down plastic paver edging. The Gator brand sells special screws that allow you to attach the edging directly to the paver mats. You’ll find paver edging at home centers and landscape supply stores.

Five things you’ll need: #5

Sand or polymeric joint sand

Some manufacturers specify filling the joints between pavers with polymeric sand. This helps lock the pavers together and provides a maintenance-free joint that sheds water well. If you use polymeric sand in the joints, follow the installation instructions carefully to avoid discoloring the paver surface and to prevent problems.

Remove the topsoil and install the sand

Skim off the top layer of grass and topsoil (about 3/4-inch) in the area where you plan on installing the pavers. Install the sand over the top soil and then screed it and tamp it to make the surface level.

Lay panels on leveled sand

Place the paver base panels over the sand, staggering them to avoid continuous seams.

Install the pavers

Install the pavers as you would over a conventional gravel base. An advantage of this system is that the screeded sand is protected by the panels, so you’re unlikely to mess it up as you work.