How to Make Safe Wire Connections

Updated: Jan. 19, 2024

With the right wire nut connectors and terminals, it's fairly easy to make safe, strong electrical connections

Introduction

Making tight electrical connections is critical to a safe wiring job. If wires come loose, you could get arcing and overheating, which could lead to a fire. But thanks to reliable connectors and terminals, it's fairly easy to make safe, strong connections. Still, there are a few things you have to watch out for. We'll show you how to pick the right connector for the job, and how to prepare the wires for the best connection. We'll also show why you should spend a little extra money when it comes time to buy outlets and other devices. With careful attention to detail, you can rest easy knowing your wiring job is as safe as you could possibly make it.Tools Required

- 4-in-1 screwdriver

- Wire stripper/cutter

Making tight electrical connections for your DIY wiring job is not difficult — but it’s essential that you get it right. Buying the right supplies, preparing wires and paying attention to the little details will make your wiring job safe and reliable.

Project step-by-step (9)

Check the Label on the Wire Nuts Packaging

-

- Note: Wire nut connectors come in many sizes, and every wire nut connector is made to join a certain minimum and maximum volume of wires: The larger the wire gauge, the fewer it can hold.

- Check the list on the wire nut connector packaging to make sure your combination of wires is safe.

- Pro tip: Even though the connectors appear to be color-coded, you can’t rely on this. You have to check the label on the package or go to the manufacturer’s website to find out. Keep a range of small to large wire nut connectors and their packaging on hand so you won’t be tempted to make do with the wrong size.

Strip the Ends of the Wires

- With a wire-stripping tool, strip the ends of the wires.

- Pro tip: Check the label on the connector package for the length of bare wire to expose. For all but the smallest and largest connectors, this is usually about 1/2 to 5/8 inches.

Install the Wire Connector

- Arrange the wires parallel to each other with their ends aligned.

- Place the wire nut connector over all of the wires.

- Pro tip: Keep your eye on the wire ends until the connector covers them to make sure none slips out of position.

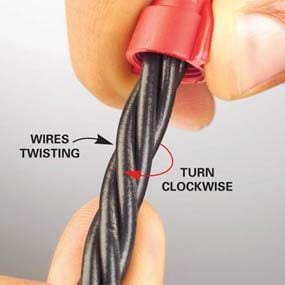

Twist on the Connector

- Twist the connector until the insulated wires outside the connector begin to twist.

- Tug on each wire to make sure they are secure.

Extend Stranded Wire by 1/8 Inch

- Extend the ends of all stranded wires about 1/8 inch beyond the solid wires.

- Then install the wire nut connector as usual.

- Note: If you hold the ends of solid and stranded wire even with each other while you screw on the wire nut connector, the stranded wire will often wrap loosely around the solid wires, resulting in a loose connection. This is especially likely when you’re joining multiple solid wires to one stranded wire.

Tip for Using Stranded Wire

Stranded wire is a little larger than the same gauge of solid wire. Use a wire stripper labeled for stranded wire, or use the hole for the next largest gauge of solid wire. Remember to tug on each wire to make sure the connector has a solid grip.

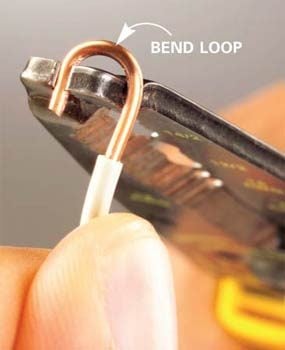

Bend Wire for a Screw Connection

- Use the point of the wire strippers to bend a 3/4-inch length of stripped wire.

- Note: Since switches and outlets vibrate a little when used, it’s critical that the connections to them be strong so they don’t work loose.

Close Loop Around the Screw

- Wrap the wire clockwise around the screw so that the loop closes as the screw is tightened.

- Tighten the screw firmly.

- Pro tip: Only one wire is allowed under each screw.

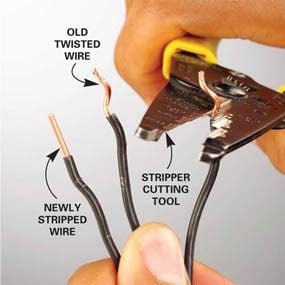

Cut Off Nicked, Bent or Twisted Ends

-

- Note: Wires that are bent, twisted or nicked are weaker and won’t nest together as easily in the connector.

- Before you reconnect wires to an outlet or switch or rejoin several wires with a connector, cut off the old bare wire ends.

- Strip the insulation to expose clean, straight wire.

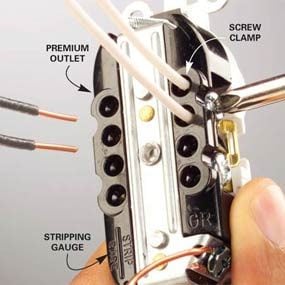

- Strip the wires to the length shown on the stripping gauge.

- Loosen the terminal screw by turning it counterclockwise to open the clamp.

- Then hold the wire or wires, one in each hole, while you tighten the screw.

- Tug on the wires when you’re done to make sure they’re securely connected.

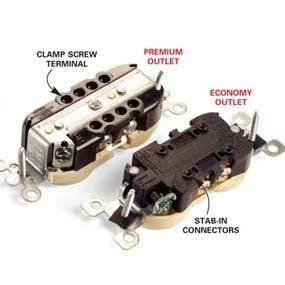

Premium vs. Economy Outlets

At most home centers, you can buy an economy outlet for about 50¢ or you can spend about $1.75 for a better one. That’s a big jump in cost for something that looks similar and does the same job. It’s tempting to buy the cheap one. But you get what you pay for. Premium outlets are stronger, make better contact with plugs and work more smoothly. Cheap outlets can literally wear out if you use them frequently. If you decide to buy premium outlets, look for the kind with clamp screw terminals. They resemble the ‘stab-in’ holes you’ll find on economy outlets but actually clamp down firmly when you tighten the screw. If you don’t want to spend the extra money to install premium outlets everywhere, at least put them in heavy-use areas like kitchens, garages, workshops and laundry rooms. Some of these areas may require GFCI protection. Always check with your local electrical inspector before replacing outlets.