How to Cover Popcorn Ceiling With Drywall

Updated: Feb. 05, 2024The perfect solution for an ugly ceiling

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $101–250

Overview

Covering an old ceiling with new drywall is a big job—it requires an understanding of basic drywall skills, heavy lifting, a serious time commitment and a major mess. But in some cases, it’s the smartest way to go. We talked to a dozen remodelers, and every one of them made the same point: In many cases, covering up an old ceiling saves time, money and headaches in the long run.

One of the best things about a ceiling cover-up job is that you can cut holes in the ceiling without fussy repairs later. So it’s the perfect time to add or move light fixtures, install a ceiling fan or run networking cables. If there’s living space above the ceiling, you can even fix floor squeaks or run new plumbing for a future bathroom remodel.

We’ll focus on the details that make this job different from other drywall projects. Go to the drywall section for everything else you need to know about hanging and finishing drywall.

Is this the solution for your problem?

Damaged drywall—The ceiling shown in this article had flaking texture, plus stains and holes, so covering it all with a new layer of drywall was actually faster and easier than repairing it. If you have only a few holes or stains, repairing them probably makes more sense. While you’re at it, get to know the difference between sheetrock and drywall.

Popcorn ceiling—If you have a heavily textured ceiling and just don’t like the look, you have a few options. With unpainted texture, the most common approach is to mist it with a spray bottle and scrape off the softened texture. Removing popcorn ceiling that way makes a big, sloppy mess and almost always leaves you with repairs to do afterward.

With painted texture, some pros scrape as best they can and then ‘skim coat’ the entire ceiling with a thin layer of joint compound. Scraping dry texture is a dusty mess, and skim coating requires some practice. And if your home was built before 1979, the texture might contain asbestos, which can do serious damage to your lungs. So before removing texture, it must be tested (you’ll find lots of labs and instructions online). You can remove texture that contains asbestos yourself as long as you carefully follow safe procedures. For all of these reasons—mess, time, skill level, asbestos—covering a ceiling is often easier than removing texture.

Cracked plaster—If you have a plaster and lath ceiling with a few short, tight cracks, repairing them is probably smarter than covering the ceiling. But if cracks span the entire ceiling or the plaster alongside the cracks feels loose when you press on it, making lasting repairs is tough. Plaster cracks often come back, even after careful repairs. That’s why several pros told us they routinely cover plaster ceilings: it’s the best way to be sure that they won’t have to come back and repair the ceiling again in a year or two. Remove any loose or sagging plaster before covering the ceiling.

Money, time and materials

For a 12 x 12-ft. room, the total materials bill will fall in the neighborhood of $160, including drywall, joint compound, paint and drywall lift rental. With a helper or two, you can cover an average-size ceiling in one day. Finishing, or “taping,” all the joints is much more time-consuming and requires drying time between coats. Then comes sanding and painting. Even if you can devote a few hours every evening to this project, expect it to span at least a week.

We recommend 1/2-in.-thick “light-weight” drywall for this project. It’s not only lighter than standard drywall but also stronger, so you can hang it from joists centered 24 in. apart. UltraLight, High Strength Lite and ToughRock are some brand names you’ll find at home centers. If possible, get sheets that are long enough to span the room. Shorter sheets are easier to handle, of course, but you’ll pay dearly for that convenience when it’s time to finish the “butt joints” where ends of sheets meet. Unlike the tapered joints along the long edges of drywall, butt joints are tough to finish. Avoid them if you can.

Most home centers carry 8- and 12-ft. sheets. Specialty drywall suppliers usually carry those lengths, plus 10-, 14- or even 16-ft. sheets. Just be sure you can get long sheets into the room before you buy; sometimes 8-ft. sheets are the only option. Everything else you’ll need is available at home centers: 2-in. screws, 10-ft. lengths of 1/2-in. tear-away bead, mud rings for junction boxes, joint tape and compound, primer and paint.

Video: How to Cut Drywall

Expert advice from veteran drywall contractor Mike Ferguson

A drywall lift doesn’t just make the job easier; it helps you do the job better. When you’re raising sheets by hand, you’re just dying to drive a few screws so you can put your arms down. With a lift, you can take your time, trim the sheet if necessary and get everything just right.

Expert advice from Senior Editor Travis Larson

I love self-feed screw guns because they’re fast: You just pull the trigger and push to automatically load and drive screws. Plus, the gun itself is long, so you can reach an 8-ft. ceiling without a ladder. Aside from drywall, I’ve used my gun for screwing down subfloors and decking too. The only thing I don’t like about it is that it’s usually missing from my toolbox, on loan to friends. You can get a corded version at any home center for about $100. A cordless one costs about $150.

Step 1: Hanging the drywall

This project is a lot like any other drywall job. But there are a few differences. For starters, you’ll have to ‘fur down’ joists at holes in the drywall (Photo 1). Don’t try to simply span holes larger than 6 in. with drywall; your screws will pop right through the hollow space above the drywall. Also, shut off the power and remove any light fixtures in the ceiling. Next, take your time to carefully locate and mark the centers of joists (Photo 2). The rest of the project will go a lot smoother if your marks are accurate. The final prep step is to extend junction boxes with ‘mud rings’ (Photo 3). If you have recessed lighting in the ceiling, you’ll have to lower the cans by loosening screws inside the housings, but it’s best to do that after the new drywall is up.

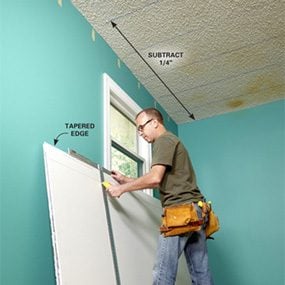

Now you’re ready to head for the rental center to pick up a drywall lift ($40 per day) and hang the drywall. You can hang drywall without a lift, of course, but a lift makes the job faster, easier and better. When you cut the rock to length (Photo 4), remember to subtract 1/4 in. for the gap along walls. But you don’t have to be exact about this: As long as the gap is between 1/8 in. and 1/4 in., you’ll have no trouble installing the tear-away bead. Here’s another critical thing to remember: Along walls, cut the tapered edge off the sheet. Because tapered edges are thinner than the rest of the sheet, they’ll cause trouble when you mud the tear-away bead later.

Raise and position each sheet (Photo 5). Take your time. Make sure it’s aligned with the chalk line that marks the center of the joist. There’s no need to completely fasten the sheets before removing the lift. Just drive enough screws to safely hold the sheet (Photo 6). When all the sheets are up, snap a fresh set of chalk lines and add the remaining screws.

Joist direction matters

Drywall is normally hung perpendicular to the joists. But sometimes it’s smart to break that rule. Let’s say you have an 11 x 14-ft. room with joists spanning the 11-ft. length (as shown here) and that you can’t get sheets longer than 12 ft. into the room. You could run sheets across the joists as usual, creating three hard-to-finish butt joints (Figure A). Or you could run the sheets parallel to the joists (Figure B) and eliminate butt joints completely.

Step 2: Terrific tear-away bead

The usual way to finish the joint where walls meet the ceiling is to apply coats of joint compound. Making it all smooth, straight and square takes patience and practice. Plastic tear-away bead lets you skip all that. Tear-away bead is typically used where drywall meets a different material like brick, a shower surround or paneling. But for this job, it’s an even bigger time-saver because it makes taping much easier—and you may not even have to paint the walls when you’re done.

The bead is easy to cut using metal shears. Make miter cuts at corners (some installers simply overlap the beads, but that leaves an uneven guide for your knife). The same goes for splices along a wall: Butt the two sections together neatly; don’t overlap them. Staple the bead to the drywall every 8 in. (Photo 7). Take your time and make sure the bead is tight against the wall. Gaps will look bad and possibly cause you more work later. When the tear-away bead is up, you’re ready to skim on the joint compound (Photo 8).

Paint the ceiling before you pull off the tear-away bead’s flange. The flange will keep ceiling paint off the wall. For extra protection, run a strip of painter’s tape below the bead (we skipped this step—and regretted it). When the paint is dry, run your utility knife along the bead at the point where the flange will tear off. Press lightly; the purpose is to slice through the paint so the paint film doesn’t tear when you pull off the flange. A needle-nose pliers helps you get a grip on the flange as you begin to tear it off. Then simply pull down to remove the bead (Photo 9) and check out the result.

It won’t look exactly like a standard wall-to-ceiling joint. Instead, you’ll see a tiny crack between the wall and the ceiling. If your walls are a deep color, that crack will be almost invisible. With white walls, the crack is visible, but only if you’re looking for it. If you’re especially fussy—or if you didn’t fasten the bead tightly along the wall—you can caulk the crack. Even with caulking and paint touch-up, tear-away bead saves hours of time and effort.

Expert advice from Field Editor Tom Dvorak

I’ve sheeted over dozens of ceilings and always finish up with a knockdown texture. Ceilings show every little flaw in the taping job, and knockdown is the easiest way to hide them. To see how I apply knockdown texture, see How to Apply Knockdown Texture.

Additional Information

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Caulk gun

- Chalk line

- Drywall sander

- Drywall saw

- Dust mask

- Extension cord

- Framing square

- Knockdown knife

- Mud pan

- Safety glasses

- Screw gun

- Taping knife

- Utility knife

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- Drywall screws

- Drywall sheets

- Joint compound

- Painter's tape

- Tear-away bead