How to Splice Automotive Wires

Updated: Jan. 29, 2024

Use a professional tool and moisture sealant for first-class results.

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.

Introduction

Use a professional crimper and electrical moisture sealant to make quick, solid connections in auto wiring.Tools Required

- Crimper

Materials Required

- Butt connectors

- Electrical moisture sealant

Project step-by-step (3)

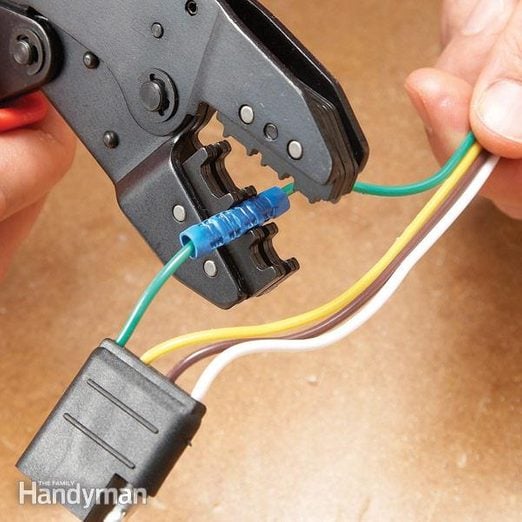

Crimp the Connector

Crimp-on wire connectors work well if they’re crimped properly (a 5/16-in.-wide crimp) and sealed (usually with heat-shrinkable tubing). But most cheap crimping tools only make a 1/8-in. crimp, so you’d have to make four of them for a simple butt connection. Buy a professional crimping tool and a roll of electrical moisture sealant.

Strip the insulation so only the bare wire is inside the connector. Then make a single 5/16-in. crimp on each side of the butt connector.

Cut the Moisture Sealant

Cut a section of moisture sealant to cover the entire connector and a 1/2-in. overlap on each end.

Seal the Splice

Double it over and squeeze it together with your fingertips.