How to Change Brake Pads

Updated: Jun. 02, 2023How to change brake pads is simpler than replacing rear disc brakes. If you have experience with basic repair brake pad replacement can be done in 4 hours.

- Time

- Complexity

- Cost

- A full day

- Intermediate

- Varies

How to Change Brake Pads: Brake pad replacement

If you’ve done some basic wrenching like replacing starter motors, alternators or even mufflers, you’re completely capable of doing your own brake job. We’ll show you how to do the front brakes on a late-model vehicle and get you up to speed on the newest techniques on how to change brake pads. Learning how to change brake pads takes about four hours and will save you about $350 in shop labor.

Rear disc brakes are far more complex, so that’s a job you should leave to the pros. (To learn how to tell whether your front or rear brakes need replacing, see How to Check Brakes. Get more information about brake pad replacement costs and how to avoid getting ripped off.)

A car that’s used mostly for city driving will need new front brakes and rotors about every 40,000 miles. But cars that are driven mostly on highways can go almost 80,000 miles before the front brakes wear out.

Get the parts and gather the tools for brake pad replacement

A shop can determine whether a rotor can be reused as is or resurfaced with an on-car brake lathe. Since you don’t have access to an on-car lathe and probably don’t own a brake micrometer, just plan on buying new rotors and brake pads. Choose the premium offerings from a name brand manufacturer to get the longest life and best service out of your new brakes. (Bendix, Raybestos, EBC, Wagner, Brembo and Akebono are examples of well respected brands.) Buy the same type of brake pad that was installed at the factory—the auto parts store has that information.

You’ll also need a small packet of synthetic high-temperature brake grease, aerosol brake cleaner, polishing pads, a tube of nickel anti-seize and a packet of blue and red thread locker (Loctite is one brand).

Tools to Change Brake Pads

Next, gather your socket set, torque wrench and screwdrivers, along with a drill and wire wheel, an 8-in. C-clamp, a small spool of mechanic’s wire, 2 ft. of 1/4-in. vinyl tubing and a jar to hold the brake fluid that bleeds out as you compress the caliper piston.

Work On One Side At a Time

Brakes on late-model vehicles include clips and springs that must go back in exactly the same position. If you remove both brakes at the same time and forget how to reinstall the small parts, you won’t have the other side to use as a reference (a common DIY mistake). So replace the brakes one side at a time in this how to change brake pads project.

Start by loosening (not removing!) the lug nuts while the tire is on the ground. Raise one side of the vehicle with a floor jack or spare-tire jack. Then place a jack stand under the engine cradle for added safety. Then remove the tire and proceed with changing brake pads.

Unbolt the caliper

Remove the wheel. Then loosen the caliper retaining bolts with a socket and ratchet (Photo 1). Next, loosen the caliper bleeder screw and lightly reseat it. You’ll loosen it again when you retract the caliper piston. Then lift the caliper off the rotor and set it on top of the caliper bracket.

You Might Need Hex- or Star-Shaped Sockets

The brake caliper bolts on older vehicles usually have an internal hex or internal star-shaped head. You won’t have enough leverage to remove an internal hex-head caliper bolt with an ordinary L-shaped Allen wrench. So before you begin the changing brake pads, turn the front wheels all the way to one side and crawl under the vehicle with a light. Check the caliper bolts to see if they’re internal hex or internal star. Then buy a complete set of the correct sockets to have on hand when you start the job.

Remove the caliper, retract the piston

Connect one end of the drain tube to the bleeder screw and place the other end in a catch jar. Then open the bleeder and force the caliper piston back into the bore with the C-clamp (Photo 2). When you’re done, tighten the bleeder and disconnect the drain tube. Secure the caliper to the coil spring or strut with mechanic’s wire while you complete the brake job. Never let the caliper dangle by its hose.

Next, remove the caliper bracket so you can replace the rotor. The caliper bracket bolts are quite large and are usually coated with thread locker. So you’ll need a large ratchet or breaker bar or an impact wrench to remove them (Photo 3).

As you remove the bolts, note whether they’ve been coated with red or blue thread locker. Recoat the threads with the same type when you reinstall them.

Remove the rotor

Many carmakers secure the rotor to the hub with a screw, and it rarely comes out without a fight. So assume it’s rusted in place and soak it with spray rust penetrant before you try to remove it. Otherwise you can strip the head, and you’ll be forced to drill it out. Let the penetrant work for about 15 minutes. Then remove the screw (Photo 4) and pull the rotor off the hub.

It’s all about clean

Brake noise, vibration, harsh braking and brake pedal pulsation are the most common brake complaints, and they’re all caused by improper cleaning and installation procedures. So trust us on this point and follow all of our cleaning and greasing instructions on how to change brake pads.

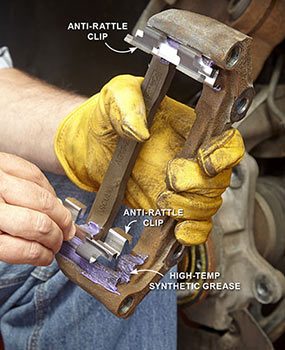

Remove the old anti-rattle clips and toss them (they can’t be reused). Then clean all the rust off the caliper bracket (Photo 5). Next, clean the caliper bolts with aerosol brake cleaner and check for corrosion. Replace the bolts if they’re corroded. Install new anti-rattle clips (Photo 6). Then grease the bolts and install new rubber boots (Photo 7).

Then clean all the rust and debris from the wheel hub. All it takes is .003 in. of rust or crud on the hub to cause brake pedal pulsation and ruin a perfectly good brake job. So take this part seriously. Chuck a mildly abrasive polishing pad into your drill and clean the wheel hub (Photo 8).

Next, clean the new rotors. Use aerosol brake cleaner to remove the rust preventive coating. Then perform the second cleaning step shown here (Photo 9). It’s a pain, but skipping this step can also ruin your brake job.

Reassemble

Slide the rotor onto the hub, aligning the rotor retention screw hole with the threaded hole in the hub. Tighten the screw to specs. Next, apply the correct thread locker to the caliper bracket bolts and reinstall the caliper bracket. Apply a thin film of brake grease to the back side of the noise reduction shims, slide them into the caliper bracket and install the springs (Photo 10). Reinstall the caliper.

Install the wheel, torque the lug nuts, and test the brakes

Now that you’ve followed all the cleaning and greasing tips, don’t wreck your work by using an impact wrench or ratchet to tighten the lug nuts. They must be tightened to the same torque to maintain the critical rotor-to-hub fit (Photo 11). If they’re torqued unevenly, the rotor will cock slightly and you’ll get pedal pulsation.

Caution! You won’t have immediate braking at this point, so don’t start the engine or put the car in gear until you perform this next step.

Depress the brake pedal several times with the engine off until you get a firm pedal. Then go for a test drive at slow speed to be sure the brake pads work. Finally, perform the “bedding” procedure recommended by the brake pad manufacturer (see “How to Break in Brake Pads” below).

How to Break in Brake Pads

After replacing brake pads, they must be correctly “burnished,” or “bedded,” for proper operation. This step transfers a thin film of friction material onto the rotor and polishes the face of the brake pad. Consult the brake pad package insert for the recommended procedure. Most manufacturers recommend this 30-30-30 method: You accelerate to 30 mph and gently brake to a complete stop. Wait 30 seconds for the brakes to cool. Then repeat the procedure 30 times. (Perform the break-in procedure in a quiet parking lot or on a traffic-free road!) If you skip this critical break-in step, you might experience shorter brake pad life, along with noise and vibration.

Required Tools for this How to Change Brake Pads Project

Have the necessary tools for this how to change brake pads DIY project lined up before you start—you’ll save time and frustration.

- 4-in-1 screwdriver

- C-clamps

- Cordless drill

- Rags

- Socket/ratchet set

- Wire brush

Required Materials for this How to Change Brake Pads Project

Avoid last-minute shopping trips by having all your materials ready ahead of time for this how to change brake pads project. Here’s a list.

- 1/4-in. vinyl tubing

- Aerosol brake cleaner

- Anti-rattle clips

- Blue and red thread locker

- Brake pads

- Glass jar

- Mechanic's wire

- Nickel anti-seize

- Polishing pads

- Rotors

- Synthetic high-temperature brake grease