How to Use a Fertilizer Spreader

Updated: Aug. 11, 2023This must-have lawn tool spreads everything you need for a healthy, attractive lawn.

Overview: How to use a grass seed spreader

Maintaining an attractive lawn takes not only lots of hard work, knowledge, timing and good weather but also the precise (and seemingly endless) application of the proper seed, soil builder and chemicals. Each product you apply requires a different spread rate. Too much is wasteful and could kill your lawn; too little won’t do the job.

A good fertilizer spreader can apply just the right amount of product. The key is to choose a model that has an adjustable spread rate setting to deliver the product uniformly and in accurate amounts to the left, center and right while applying the recommended volume for your lawn size.

Grass seed spreaders are reasonably priced and widely available from garden and home centers. We’ll show you how to use your grass seed spreader more effectively to save time and make your lawn more attractive.

Two Types of Fertilizer Spreaders and How They Work

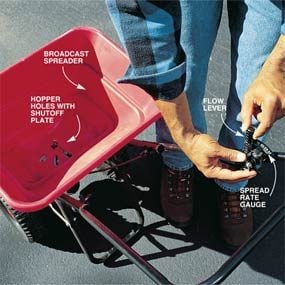

Broadcaster spreaders and drop spreaders are push-powered workhorses that share many features in common. At the heart of both is a hopper with adjustable holes in the bottom. A gauge mounted on the spreader’s handlebar allows you to accurately set the size of these holes (following the recommended setting listed on many bags of lawn products), allowing the proper volume of material to uniformly exit the hopper. Alongside the gauge, a flow lever controls when the material drops onto the lawn by opening and closing a plate under the hopper holes. But the two machines have their differences, too.

Drop spreaders lay a trail of material the width of their hopper (less than 24 in.). They work best on small lawns and in yards with numerous flowerbeds, sidewalks or patios where you need to carefully control the spread pattern. Unless you’re meticulous about lining up adjacent passes, the payload either is laid too thick or misses portions of the grass, resulting in visible striping.

Broadcast spreaders are the choice of the pros and the focus of our story. Broadcasters work best for yards larger than 4,000 sq. ft. They deliver their payload more quickly over a wider area—and without striping the lawn. One of their wheels is geared so that as you push the broadcaster, the drive wheel turns a whirling impeller plate under the hopper that catches and throws the payload. When the shutoff plate is open, the impeller broadcasts the material in a 180-degree arc 7 ft. to 11 ft. wide (depending on the product’s granular size and your walking speed).

The best operating techniques

The key to operating a broadcaster spreader is to achieve even dispersal at the right concentration. To do this:

- Dial in the product manufacturer’s recommended setting on the spread rate gauge (Photo 2), and test and measure the product’s dispersal pattern through the spreader (Photo 3). First, sweep dirt and debris off your driveway and then conduct the dispersal pattern test. With a broadcast spreader, the right side of the dispersal pattern will be a foot or two wider than the left. Use this test information to establish the pattern you’ll use to push the spreader across your yard for total coverage with 6 in. to 1 ft. of overlap. Write this “wide side,” “narrow side” measurement information on a piece of masking tape and stick it to the back of the hopper so you don’t forget the broadcast pattern for each side. Important: Don’t sweep, blow or wash this test material into the street. Sweep it up and dump it back in the hopper.

- If the product doesn’t list a recommended setting for your spreader, consult your owner’s manual for generic equivalents of each product. Otherwise you’ll have to resort to trial and error. Set the spreader to a light coverage (try a 1/4-in. to 3/16-in. hole in the hopper), apply the product over the recommended square footage, and check how much product you have left in the hopper. Adjust the dial to spread the remaining material over the same area, going perpendicular to the first pattern.

- Begin your yard pattern by spreading across hills first. This way, you’ll have enough lawn product in the hopper to reduce “skipping” over the uneven terrain.

- Maintain the pace you’d use to take a middle-aged, midsized dog for a walk (about 3 mph). Your walking speed affects how wide and how much product the broadcaster throws. Walking too slow reduces the throw width and increases product density; walking too fast thins out the coverage.

- Each time you’re ready to stop or make a turn, close the flow lever to stop dispersing the product and continue one more stride. This reduces waste and avoids damaging the lawn from saturated product coverage. Avoid pulling the spreader backward when the flow lever is open; you’ll release more of the product.

- Operate the spreader, keeping the impeller plate close to level (Photo 4). Tilting the handlebar up or down from level throws the product too high or low, resulting in uneven coverage.

- Don’t overapply fertilizer and weed killer. Follow the recommended coverage rate for each product. Overuse and overapplication can lead to lawn runoff that contaminates lakes and streams. Protect yourself by wearing gloves and a nuisance dust mask when handling chemical lawn products that contain pesticides and herbicides.

Figure A: Optimal Fertilizer Spreader Pattern

Follow this optimal pattern for running the broadcaster spreader. Apply a “header strip” by circling the spreader once around the yard’s perimeter. Avoid throwing the material payload into adjacent flowerbeds by running the spreader back from those areas the distance your driveway test (Photo 3) showed. Complete the pattern by pushing the spreader on a serpentine route back and forth in the longest direction on the lawn while overlapping the throw patterns about a foot. Shut off the flow lever as you near the end of a row, when the spreader’s within 5 ft. of the header strip. Keep the lever off during the turn and open it to begin the new row.

Buying and maintenance tips

We recommend you spend a little more to buy a better-quality broadcaster spreader with these features:

- High-impact polypropylene hopper and tubular steel handles with a baked-on finish for a longer, rust-free life.

- Hopper capacity of at least 25 to 30 lbs. of product so you’ll spend less time refilling the spreader.

- Large, 8- to 10-in. wheels—preferably high-impact plastic—for easy rolling over bumpy lawns.

Using a garden hose, quickly rinse out the grass seed spreader every time you change lawn products. When you’re finished using the spreader for the day, invest 15 minutes in maintenance to prolong its life. Lay the spreader on its side and use a forceful blast from a garden hose to thoroughly clean the hopper, wheels and impeller plate. Operate the flow lever back and forth and wash off the shutoff plate inside the hopper. After the broadcaster is dry, periodically use a light lubricant spray like WD-40 to protect all moving parts, the axle bushings on the wheels and the gear-box. Avoid lubricants that contain Teflon or silicone. They may seal in certain chemicals from the fertilizers and speed up corrosion.

Required Tools for this grass seed spreader Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Broadcast spreader

- Dust mask

- Tape measure