Mineral Stone Wool Insulation is Making a Comeback. Here’s Why

Updated: Sep. 02, 2021An old product with big advantages makes a comeback

R-Value

Mineral stone wool insulation batts are slightly better insulators than the off-the-shelf fiberglass batts sold at most lumberyards and home centers. Mineral wool batts for 2×4 walls have an R-value of 15, while a standard fiberglass batt made to fit in a 2×4 wall has an R-value of 11 or 13. However, you can special-order R-15 high-density fiberglass batts. (The larger the R-value, the better insulator the material is.)

Mineral wool batts for 2×6 walls have an R-value of 23, compared with R-19 for fiberglass batts. A 2×4 stud cavity filled with blown-in cellulose has an R-value of about 13. Spray foam insulates better than all of these, but it’s far more expensive.

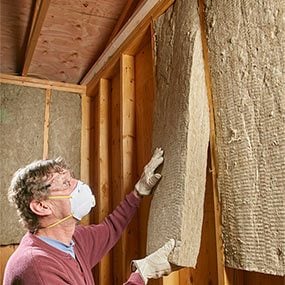

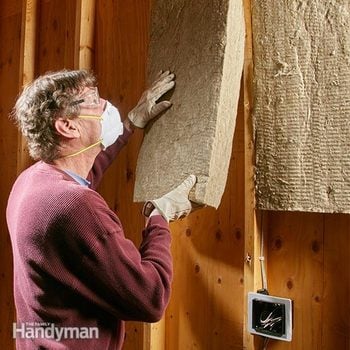

Installation

It’s much easier to do a top-notch insulation job if you use mineral wool instead of fiberglass. Because of its greater rigidity, mineral wool can be cut more exactly, allowing precise trimming around outlets and other obstructions. By contrast, fiberglass batts simply aren’t easy to install accurately. They’re floppy, hard to cut precisely, and prone to overstuffing.

Cost and Availability

On a square-foot basis, mineral wool batts cost more than fiberglass batts. As an example, the R-15 mineral wool costs about 80¢ per sq. ft. vs. 60¢ for fiberglass. There are at least three brands of mineral wool batts for thermal wall insulation: Johns Manville TempControl, Roxul ComfortBatt and Thermafiber UltraBatt. Be aware, though, that you may have to special-order mineral wool batts. We used Roxul r value insulation batts.

Fire Resistance

Mineral wool withstands extreme heat better than other types of insulation. In a fire, the batts retain their shape and offer better protection against flame spread. And you builders may be interested to learn that when they’re combined with special fire-rated sheathing, mineral wool batts can be used to create a one-hour-fire-rated assembly without any extra labor.

Water Resistance

Another cool property of mineral wool batts is that they don’t absorb water, staying intact even when wet. This means that if your wall or roof leaks, the batts will be as good as new after they dry out. Fiberglass or cellulose, on the other hand, droop, clump up or compress when they get wet. And sometimes, the only way to restore their insulating value is to tear off the wall covering and replace them. When it comes to water resistance, only foam insulation beats mineral wool.

The Itch Factor

Like fiberglass, mineral wool contact can make you itch or even cause a mild rash. Some installers say it’s a little worse than fiberglass; some say a little better. I can’t tell the difference. Regardless of which material you install, be sure to wear a dust mask, goggles, gloves and a longsleeve shirt.

Sound Blocking

Mineral wool batts are denser than other types of stone wool insulation, making them better at soundproofing interior walls, floors and ceilings. Install batts between rooms or in the joist spaces between floors to reduce sound transmission.