How to build an interior stone accent wall

You can transform any interior room with a stunning stone accent wall like this. Modern materials and methods allow contractors to create the look of a traditional stone wall with a fraction of the work. In this story, we’ll show you how to install stone veneer on any interior wall of any home.

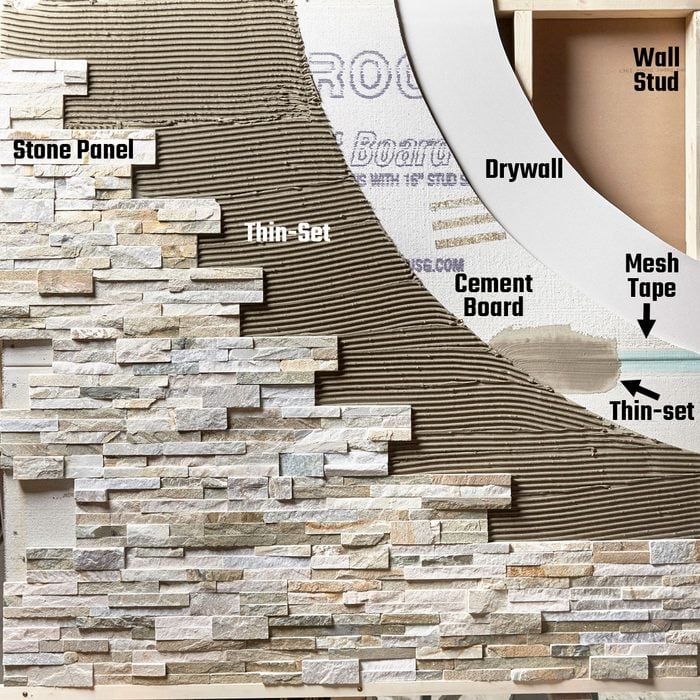

How stone veneer interior accent walls work

To provide a strong base for the stone, cement board is attached to the wall framing with screws. Thin-set adhesive to bonds the stone panels securely to the cement board for a worry-free installation. The existing drywall can stay or can be torn out first. Ledgestone panels like the ones shown here don’t require mortar—just stack them on the wall.

Getting started: room preparation

Installing the stone will go a lot smoother and easier if you take some time to prepare the space. Start by moving everything out of the room. Parts of this job can be dusty, and you don’t want to have to clean everything later. What you can’t move out, cover with sheets of painter’s plastic. Cover carpeted flooring with drop cloths. Protect hardwood and tile floors with a layer of cardboard or thin hardboard before covering them with drop cloths.

Pry off the baseboard trim on the wall where the stone will go, and on adjacent walls. If you’ll be reinstalling the same trim, pull the nails from the back of the trim with an end cutter or a locking pliers. If you have chair rail or crown molding, you’ll have to remove these, too.

To save a little time and effort, we’re showing how to install the new cement board on top of the existing drywall. But if you want to add outlets or sconce lights or do other extensive wiring, it may be easier to remove all the drywall from your wall.

If you decide to leave the drywall in place, mark the center of each stud with a chalk line so you’ll know where to drive the cement-board screws. First use a stud finder or some other method to locate the center of each stud at the top and bottom of the wall. Then stretch a chalk line between the marks and snap the lines.

Score the cement board

Mark the cement board and line up your drywall square with the mark. Drag the tip of the scoring tool along the edge of the square to score the cement board. Repeat two or three times until you cut through the fiberglass mesh reinforcing.

Break the board

Bend the cement board to snap it along the scored line. Then cut through the mesh on the back of the board with a utility knife. Use the utility knife to clean up the cut and create a straight edge.

Since you’ll be adding cement board and stone to the wall, existing switches and outlets will have to be moved out to the surface of the stone. There are a few options for doing this. We added electrical box extensions (see below).

Be sure to turn off the power to the switch or outlet before doing any work on them. When you add a box extension, it’s possible that the old wires connecting the switch or outlet will be too short. If your wires don’t extend 3 in. past the face of the box extension, add pigtails.

Screw cement board to the studs

Cut the cement board, making sure the ends of the sheets are centered on a stud. Use your utility knife to clean up the cut end by carving off any protruding chunks of cement. Attach the sheets with 2-1/4-in. screws spaced every 8-in. Be sure to stagger the seams.

Break out outlet openings

Mark the outlet location on the cement board. Score all four sides and then score an “X” through the center. Tap with a hammer to create the outlet hole. Then clean up the edges with your utility knife. Remember, you’ll be covering the cement board with stone, so this hole doesn’t have to be very accurate.

The final step in the cement-board installation is to reinforce the seams with self-adhesive mesh tape covered by a layer of thin-set. Apply the tape to the seams. Then mix a small batch of thin-set to about the consistency of peanut butter and trowel it over the tape. (See below)

Figure horizontal and vertical starting spots

To figure out the side-to-side layout, start by measuring between the walls. Then lay a row of stone on the floor, a little longer than the distance between the walls. Use your tape measure to see what the last cut would be if you started with a full stone on one end. If the last stone will need to be cut less than an inch long, plan to cut several inches off the first stone to allow for a wider finishing piece.

To ensure that the first course is straight and level, snap a level chalk line on the wall to indicate the top of the first row of stone. Using a 4-ft. level or a shorter level held on top of a straight board, check to see whether the floor is level across the width of the wall. If the floor is level, use the measurement you determined using the measuring stick to mark the distance from the floor to the line at each end of the wall, and snap a line. If the floor isn’t level, measure up from the low side and level across the room to make a mark at the other end. Then snap a line between the marks. See where to snap the line below.

Avoid skinny rows on the top and bottom

You’ll need to figure out the horizontal cuts where the stone meets the floor and ceiling. It’s tempting to measure down from the ceiling and start your stone so that you’ll end up with a full piece against the ceiling. But doing this is likely to cause you problems. So instead, plan on cutting both the top and the bottom rows to fit against the floor and ceiling.

Start by measuring the distance from the floor to the ceiling. Then cut a 1×2 or other spare piece of lumber to this length. You’ll use this measuring stick (called a ‘story pole’) to determine the best stone layout. Arrange stone on the floor to create a stack a little longer than the length of the story pole. Set the story pole on the stack of stones and move it up or down until you find a position where both the top and the bottom stones will need to be cut to fit, without leaving a sliver on either row. When you’ve found a good spot, mark the stone at the bottom of the stick. Measure from this mark to the top edge of the bottom stone.

In our case, this distance was 5-1/2 in. You’ll use this measurement to position the starting chalk line. Mark the height of the first row of stone on each end of the wall and snap a level chalk line between the marks to indicate the top of the first row.

Cut ends with a tile saw

Mark the stone and set it on the sliding table of your tile saw. Line up the mark with the blade. Turn on the saw and simply slide the table toward the blade to cut through the stone.

Cut the first row of stone

Mark the stone pieces to fit between the chalk line and the floor. Align the mark with the tile saw blade and cut along the line. If your saw won’t cut the full length, flip the stone around and finish the cut from the opposite end.

Spread thin-set for the first row

Mix thin-set and spread it just below the chalk line with a notched trowel. Press a test piece of stone into the fresh thin-set. Pull it off and check the back to make sure it’s fully covered with thin-set. If not, use a trowel with larger notches or butter the back of the stone.

Align the first row with the chalk line

Cut and dry-fit the first row of stone before you mix and spread any thin-set. The first course takes a little longer because you have to cut it to fit to the line, but after that, the stone will go up quickly. Measure from the floor to the line and subtract 1/8 in. to determine the height of the stone pieces. If you’re having trouble seeing the cutting line because it’s being washed off by the wet-saw spray, apply masking tape to the stone before you mark it, and then draw the line on the tape.

When the first row of stone is ready to install, mix a bag of thin-set mortar according to the instructions on the package, using a 1/2-in. drill and a mixing paddle. Spread thin-set below the line using a 1/4 x 3/8-in. notched trowel. Press the first piece of stone into the thin-set. Then remove it and check the back to make sure it’s completely covered with thin-set. If not, you’ll have to use a 1/2 x 1/2-in. notched trowel instead, or ‘butter’ the back of each piece of stone by spreading a layer of thin-set over it with the flat edge of your trowel, and then setting it into the thin-set on the wall. Slide plastic tile shims under the stone pieces to align the top edges with the chalk line. Press the stone pieces into the thin-set. Then slide shims underneath until the top edge is perfectly aligned with the chalk line. This will ensure that the following courses of stone will be straight and level.

The seams between the stones will be less visible if you stagger them. To do this, start the second row with a piece that’s about two-thirds as long as the piece below it, once again checking to make sure you don’t end up with a thin sliver at the far end. Spread enough thin-set to apply about two more rows of stone and work your way up the wall. Continue like this until you reach the top.

How to measure for the outlet notch

Measure from the closest installed stone and transfer these marks to the stone you need to notch. You can stick masking tape to the stone for easier marking.

Notch around outlets

Cut out the notch with the tile saw by making a series of closely spaced cuts that end at the line for the bottom of the notch. Tilt the stone up to create a square-bottom cut. Then break out the fingers and clean up the cut with a back-and-forth motion through the saw.

It’s almost certain you’ll have to cut around at least one outlet. We show how to notch the stone piece to fit, but if your outlet falls in the center of a piece, you’ll have to use a slightly different technique. Mark the outlet on both sides of the stone. Then you can either use the tile saw, or an angle grinder with a diamond blade, to plungecut on all four sides. Start on the front of the stone and plunge until the cuts just reach the corners. Then flip the stone over and plunge-cut until the center piece falls out. You may have to clean out the corners with a dull wood chisel, a glass-drilling bit in a drill, or a rotary tool. Later we’ll show you how to mount the outlet and fit the cover plate to the irregular stone surface.

Continue installing stone

Work your way up the wall, offsetting the starting pieces so the joints will be staggered and less visible.

Attach shelves with angled screws

Apply construction adhesive to the back edge of the shelf and rest it on top of a stone. Press the shelf against the wall while driving angled finish-head screws through the shelf and into studs. Make sure to position the shelves over two studs.

Cut stone to fit over the shelf

If your shelves are exactly as long as one piece of stone, you can simply cut off the thickness of the shelf from the length of one piece of stone. Otherwise, notch the stone to fit around the shelf.

We decided to add small floating shelves to the stone wall. We built ours by gluing two layers of 1×8 poplar together, cutting them to the length of one stone piece-in our case, 23-1/2 in.-and ripping them to 6-1/2 in. wide on a table saw. Then we applied ebony stain and finished them with two coats of satin polyurethane.

Plan the shelf positions by arranging strips of masking tape on the wall, making sure that there are two studs behind every shelf. Then when you reach the level of a shelf with the stone, apply construction adhesive to the back edge of the shelf, rest the shelf on the stone, and drive 3-1/8-in. finish-head screws at an angle into the studs to hold the shelf in place. Rip 1-1/2 in. from the bottom of a stone piece to fit over the shelf. You can work from the shelf toward the walls on both sides to finish the row of stone.

Cut and fit the top row

Complete the project by installing the top row of stone. Measure and cut each piece and test the fit. Then spread thin-set onto the back of the stone pieces and press them in place.

Don’t spread any thin-set in the area behind the top row of stone. Instead, apply the thin-set to the back of each piece before setting it in place. This allows you to dry-fit the piece and makes it easier to avoid accidentally getting thin-set on the ceiling. Measure between the top stone and the ceiling, and transfer these measurements to the stone pieces for cutting. Use the technique we showed you earlier to cut the top row of stones. After you’ve checked the fit, spread thin-set on the back of the stone and press it onto the cement board.

Carve a flat spot for the cover plate

Hold the cover plate in position over the outlet and trace around it. Now use a diamond wheel in a rotary tool or a 1/8-in. glass-drilling bit in a drill to carefully smooth out the stone in the area under the cover plate.

Install the box extension

Slip a plastic box extension over the outlet and slide it into the electrical box. Mount the outlet to the electrical box with the extra-long screws provided in the package.

Attach the cover plate to accent wall

Set the cover plate into place and make sure it’s tight to the stone, without large gaps. If it’s a good fit, screw it onto the outlet.

Since the surface of the stone is too irregular for mounting the outlet and cover plate, the first step is to carve away the stone to create a flat mounting surface. This isn’t as difficult as it sounds, because the area you need to flatten extends only about 3/8 in. beyond the hole in the stone.

First, make sure the power is still turned off. Then, start by temporarily connecting the outlet to the box using the long screws included with the box extension. Set the cover plate over the outlet, making sure it’s level, and trace around it. Now remove the screws that hold the outlet to the box and move the outlet of the way. We used a rotary tool with a diamond wheel attachment to cut the stone, and an old wood chisel to square up the corners. You could also use a 1/8-in. glass-cutting drill bit mounted in a drill to chisel away the stone.

Start by cutting the outline of the cover plate. Then cut away protruding stone inside the line until you have a flat surface for the cover plate. Then simply reattach the device, along with the new box extension. Finish up by installing the cover plate.