Home Tools, Gear & Equipment Tools & Supplies

Router Edge Guide: How to Get Perfect Routed Edges

Updated: Feb. 01, 2024

Tips and techniques for pro-quality profiles

Family Handyman

Family Handyman

Modern router bits with carbide cutters and guide bearings make forming wood edges almost foolproof. But there are a few tips and tricks that'll simplify the job and give you the best results.

By the DIY experts of The Family Handyman Magazine

You might also like: TBD

Don’t rout the sides before the ends

Plan the cuts

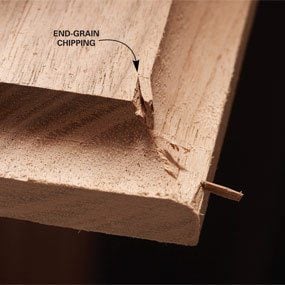

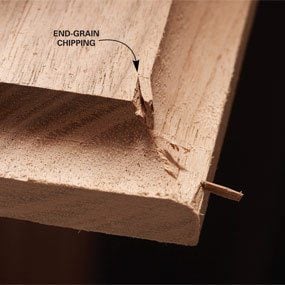

If you’re planning to rout the ends as well as one or both sides of a board, rout the two ends first. Here’s why. End grain has a tendency to split out as the bit exits the end of the cut.

Rout the ends first

Eliminate chips

If you rout the sides first, the split-out will occur on the previously shaped edge (see ‘Don’t rout the sides before the ends’). But if you rout the ends first, you’ll cut off any damaged areas when you rout the sides.

Move the router in the right direction

Outside edges—counterclockwise Inside edges—clockwise

Router bits spin clockwise as you look down on the router, so moving the router counterclockwise tends to pull the pilot bearing tight against the wood and allows easy control of the router. When you’re routing the outside perimeter of a board, move the router counterclockwise. However, when you’re routing the inside of something like a picture frame, move the router in a clockwise direction.

Hold narrow strips with stops

Lock small pieces in place

Narrow strips are difficult to rout because clamps get in the way. The solution is to screw blocks to your workbench to corral the strip of wood. If you’re routing a thin piece of wood, the bearing on the router bit will most likely extend below the piece of wood you’re routing. In this case, hang the piece of wood over the edge of the bench at least 1/4 in. so the bit doesn’t hit the workbench. Screw a strip of equal thickness behind the long edge of the narrow strip you’re routing. Then screw a thinner stop block at the end to keep the board from sliding.

Secure small work with hot-melt glue

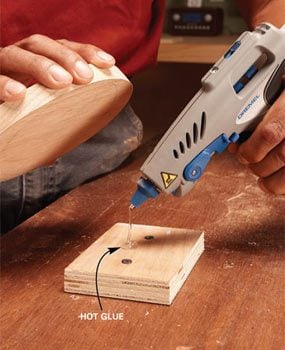

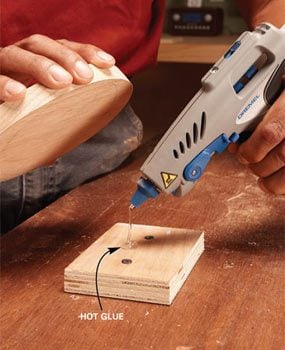

Glue-down trick

Here’s a nifty trick for securing small pieces while you rout them. Start by screwing a scrap of wood to the workbench to elevate your project and provide clearance for the bearing. The scrap should be smaller than the piece you’re routing. Then apply 1/2 teaspoon of hot-melt glue to the scrap and stick your workpiece to it. Allow it to cool a few minutes before you rout the edge. When you’re done, just twist the routed piece to break it free. Then scrape off the hot-melt glue with a chisel or putty knife.

Rout gently

Rout the glued piece gently; don’t make an aggressive cut or you could dislodge your work.

Make moldings with your router

Custom trim setup

One way to make narrow moldings with your router is to use a router table and featherboards. But if you don’t have a setup like this, try this other method. Start by routing the desired profile on a wide board. Then make the molding by cutting the shaped edge from the wide board with a table saw. Repeat the process until the board is too narrow to work with.

Router tips

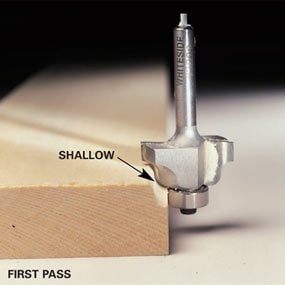

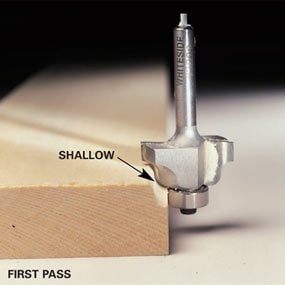

First pass

For large profiles, make a shallow first pass

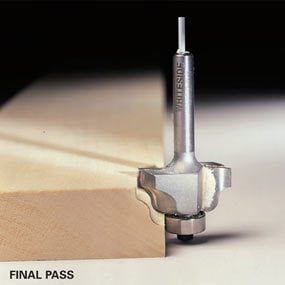

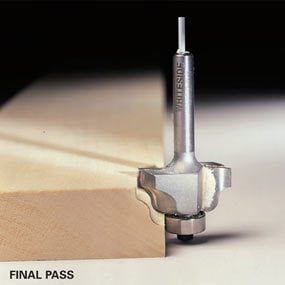

Final pass

Finish the edge with a full-depth final pass. For very deep profiles or cuts in difficult, splintery woods, make a second or even third pass before the final pass.

- Insert the router bit fully into the collet. Then pull it back out 1/8 in. before tightening the collet nuts.

- Sand the edge of boards before routing them so the guide bearing will ride on a smooth surface. If you don’t, irregularities in the edge on the board will be transferred to the routed shape.

- Press the base of the router tight to the wood surface to prevent the router from tipping. A tipped router will cut an irregular profile.

- Make deep-profile cuts in two or three shallow passes to avoid burns and chatter marks. Set the router depth for a shallow cut and rout all sides. Then adjust the router for a deeper cut and repeat the process.

- Replace your old steel bits with modern carbide bits. Carbide lasts longer and makes cleaner cuts with less effort.

- Clean your router bits with a special blade-and-bit cleaning solution to remove wood pitch. You’ll find blade-and-bit cleaner at woodworking stores.

ⓘ

Required Tools for this router edge guide

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

Edge-forming router bits range from simple round-overs or bevel bits to intricate cove, ogee and classical bits. Common profiles are sold at home centers and hardware stores; for a wider selection, check online.

Originally Published: June 20, 2017