Concrete Demolition Tools and Tips

Updated: Oct. 23, 2023Tips for a fast breakup—even if you're not a body builder

Calculate the savings first

You might think that demolishing concrete is backbreaking, brainless work. But that’s only half true. There’s more to it than just swinging a sledgehammer. And a bit of know-how can save you lots of time and sweat and possibly a visit to the chiropractor’s office.

Tearing up concrete yourself can also save you a ton of money. Hiring a contractor just to demolish a 12 x 14-ft. patio could cost you $1,400 or more. If you do it yourself, the cost to remove a concrete driveway will run you about $400, including rental and disposal. That’s a savings of about $1,000 on the cost to remove a concrete driveway. On the other hand, if you’re hiring a contractor to pour new concrete, doing the demo yourself could actually cost you more once you pay disposal costs. Compare the costs of removing it yourself with what the contractor would charge for removal.

Choose your weapon—sledge or jackhammer

The surest way to decide whether to use a sledgehammer or a jackhammer is to experiment a few days before you begin full-scale demolition. Just take a few whacks at the slab with a 12-lb. sledgehammer (Photo 1). Within 10 minutes, you’ll know whether it’s a job for a sledge or a jackhammer. Consider renting an electric jackhammer to make the job easier. It won’t save you much time, but it’s a lot easier on your body.

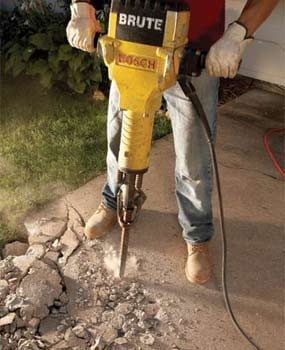

If your slab is large or extra thick, rent a pneumatic jackhammer (with a hose, bits and a trailer-mounted compressor; Photo 2). It has much more power than an electric jackhammer. But it’s also heavy (90 lbs.) and difficult to maneuver. Don’t automatically assume you should rent this as your first choice—it’s overkill for most home concrete breakup projects.

Plan your disposal strategy

Concrete can’t go in your trash can, so check out your disposal options at least a week ahead. Some concrete recyclers (search online for “recycling services”) accept it free or charge a small fee per load. Most add an extra charge if the concrete contains steel mesh or rebar. Unfortunately, you won’t know if yours has metal in it until you start breaking it apart. So figure your total price based on the higher rate. Also be aware that the typical 12 x 14-ft. patio weighs about 5,000 lbs. That means you’ll be paying the charges for at least three loads and making at least three trips, even if you have a 1-ton pickup truck.

Your other option is to rent a trash container (check the yellow pages under “waste disposal”). Don’t guess on the proper size. Instead, give the waste haulers the dimensions and thickness of your patio and let them figure out the right size for your job. Make sure any trash container you rent has a walk-in gate for easier loading.

Round up a crew

This is one project where it really pays to have extra bodies around to do the heavy lifting. So plan ahead and nail down firm commitments from friends who owe you favors. Friends who own heavy-duty wheelbarrows are especially valuable. Ideally, your crew will consist of two to break up the concrete and a team of two to four to haul the rubble away.

Stop flying shrapnel

Flying shards of concrete can damage siding, break glass or even cut you. Rather than setting up plywood to protect windows and siding, roll 6-mil polyethylene (at home centers) over the patio or sidewalk. Leave it in place while you hammer or jackhammer. The sheeting catches all the shrapnel and traps most of the dust. Just be sure to watch your step while walking on it—poly can be very slippery.

Don’t just hammer—pry, too

After you’ve covered the slab with plastic, it’s tempting to just start whaling away. Don’t! The sand base under the slab will absorb the energy from each blow. You’ll end up exhausted with very little to show for it. Worse, you’ll pulverize the top layer of the slab instead of creating deep cracks.

The key to a quick job is a two-person team: one with a sledge or jackhammer; the other with a 5 to 6-ft. long pry bar, sometimes called a “San Angelo bar” (available at some rental centers or at home centers; Photo 2). Start at the corners and work inward. If the concrete doesn’t crack with the first blow, aim your next hit a few inches away. Never strike the same spot twice. That just chips the surface, creating a cushion of fine rubble over the slab, and makes it harder to break.

How to use a jackhammer: Jackhammer tips

Rental jackhammers come with an assortment of bits, but only use the chisel-point bit (Photo 2). The point concentrates the jackhammer’s force and cracks the concrete faster than the wider bits can. Here’s an important jackhammer warning: If you try to crack off large pieces, the jackhammer will literally drill itself into the concrete and get stuck. You’ll spend more time getting it unstuck than it takes to crack more but smaller pieces. So move the bit no more than 2 to 3 in. back from the nearest crack before you hit the trigger. As with a sledgehammer, breakup is faster and easier if you have a helper pry up with a long bar as you work.

Separate the chunks

Even after concrete is broken, the chunks remain locked together, making the surrounding concrete harder to break. So clear away the rubble after you’ve broken up each 2- to 3-ft. section. Don’t use your hands to pry out the sections—a mattock is the best tool for this job. To separate the chunks, swing the pointed end of the mattock into the crack and pry up. Push the pieces far enough apart so you can switch to the larger flat blade. If the chunk won’t budge, move the mattock to the opposite side of the chunk above the flat edge under the concrete. Then lift up to ‘unlock’ the stuck edge.

Dealing with mesh or rebar

Many slabs contain reinforcing steel mesh to resist cracking. That can double or even triple the time it takes to tear out the slab. If you try to break off large pieces, the reinforcing mesh will do its job and resist cracking—making your job much harder. So it’s especially important to crack smaller sections. Cut the mesh with a bolt cutter as you work. Watch out for the sharp wire spikes left sticking out of the concrete chunks. If the concrete contains rebar, cut it with a reciprocating saw and metal blade or an angle grinder and metal cutoff wheel. While you’re at it, check out our guide to concrete grinding.

Get a heavy-duty hauler

For most jobs, a heavy-duty wheelbarrow is the best hauler for rubble. Don’t use a light-duty model—it won’t survive the day. And don’t haul big loads or you won’t survive the day. Ten full loads will wear you out faster than 20 half loads. If the path to the trash container is uphill, consider renting a power wheelbarrow.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Hearing protection

- Pry bar

- Safety glasses

- Sledgehammer

- Wheelbarrow

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 6-mil plastic