How to Build a Brick Fire Pit

Updated: Mar. 08, 2024

Enjoy a crackling wood fire in your own backyard by learning how to build a DIY fire pit.

Multiple Days

Intermediate

$400

Introduction

Build a fire pit for not much more than the cost of a flimsy store-bought fire ring. With tips from a veteran bricklayer, we'll show you how to make a fire pit in your backyard.Tools Required

- Brick hammer

- Bucket

- Concave jointer

- Concrete float

- Cordless drill

- Level

- Margin trowel

- Mason's trowel

- Safety glasses

- Spade

- Tuckpointing tool

- Wheelbarrow

Materials Required

- 120 face bricks

- 25 firebricks

- 36 in. cardboard concrete form

- 48 in. cardboard concrete form (or for less money substitute a 4x8 sheet of hardboard to make both forms)

- Five 80-lb. bags of Type N mortar mix

- One half-gallon bucket of refractory cement (sold at a brickyard)

- Ten 80-lb. bags of concrete mix

- Two 10 ft. lengths of 3/8-in. rebar

Getting Started on Building an In-Ground Fire Pit:

Advice From a Masonry Pro:

Doug Montzka, of Montkza Concrete & Masonry in St. Paul, Minn., has been in the concrete and masonry business for 23 years. He’s seen the popularity of fire pits but it’s possible to create a DIY fire pit. “I started getting requests for brick fire pits a few years ago. It isn’t rocket science, but there are a few tricks to doing the job right. A well-built masonry fire pit is rock solid, safe to use, and will easily last for as long as you own your house.”

Set Aside a Few Days

This won’t be the kind of project you can complete in an afternoon. There are a few time-consuming steps that will spread this project out over a few days. First, you’ll have to pour the footing and give it the time to set up. Then you’ll have to mortar the bricks into place.

Before Digging, Call Utility Companies

Before digging out the space for your in-ground fire pit, call your utility companies (dial 811; for more info, go to call811.com) to check the location of buried utility lines.

Also, check the fire pit code in your area. Most require a fire pit to be 25 ft. away from any structures and overhanging trees. Think about how the prevailing winds blow through your backyard.

Project step-by-step (16)

Mark Out the Fire Pit

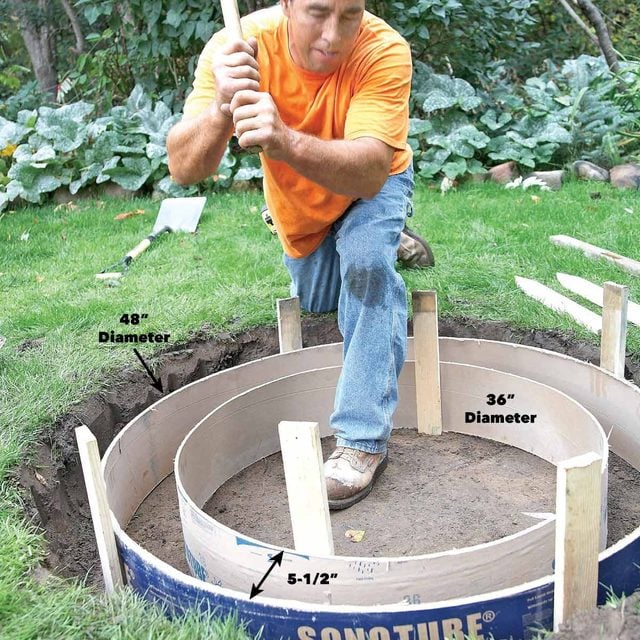

The first step to making your own fire pit is to dig out a dedicated space in your yard for the fire pit base. The following are the fire pit dimensions we used for this project.

- A 3-ft.-diameter in-ground fire pit creates enough room for a good fire, yet keeps everyone close enough to chat (and complies with most codes).

- Pro tip: To make measuring the pit and pouring the concrete footing easy, we used two cardboard concrete form tubes (purchased from a concrete supply company).

- You could also make your own forms by screwing together 1/8-in. hardboard. For a non-traditional fire, opt for a smokeless fire pit.

- Rip a 4 x 8-ft. sheet into four 8-in.-wide strips.

- Carefully bend and screw two strips together to create a 36-in.-diameter circle, and use the other two to make a 48-in.-diameter circle.

- Set the larger form in position and spray paint around it. Dig a hole about 8 in. deep and 3 in. larger in diameter than the form.

Level the Pit

- Shovel out the soil to a depth of 8 in. for your fire pit base. Don’t disturb the underlying soil.

- Check the bottom of the hole with a level.

- Remove high spots in your in-ground fire pit by scraping off soil rather than digging.

- Pro tip: That way, you won’t loosen the underlying soil.

- Compact the soil with a hand tamper or a 4×4 post.

Pour a Sturdy Footing for Your Fire Pit Base: Stake the Forms

- The concrete footing will create a stable base for the pit walls and keep the sides of your pit from cracking as the ground moves over time.

- Stake the forms and mix up ten 80-lb. bags of concrete mix according to the manufacturer’s directions.

- If you’re using hardboard forms, stake them so they’re nice and round.

- If the forms aren’t quite level, raise one end and drive a screw through the stake.

- If the forms aren’t completely round, reposition the stakes.

Add the Rebar

- Bend rebar into half circles for this circle fire pit and tie them together with wire to make a ring.

- Fill the forms halfway.

- Press the ring into the concrete for strength, making sure it doesn’t touch the sides of the forms.

Finish the Footing

- Shovel in the remaining concrete until the forms are filled to the top and tap the tubes gently with a sledgehammer until the concrete mix is level.

- Recheck level, hammering the forms down if necessary, and smooth the top of the footer.

- Let the concrete completely set up overnight and then remove the forms.

Dry-Set the Firebrick Liner

- Because regular clay brick can crack at high temperatures, we’re using firebrick (also called “refractory” brick) to line the inside of the easy fire pit walls.

- Pro tip: Firebrick is a dense brick that’s kilned to withstand high temperatures. It’s larger, thicker and wider than regular brick, and you can find it at most brickyards. Firebrick is more expensive, but it will stand up to nightly fires for years to come.

- You’ll need 25 firebricks for a 3-ft. diameter pit.

- Because firebrick is so dense, it’s tougher to split than regular brick. “Soldiering” the brick (standing it on end) minimizes the amount of splitting and lets you easily accommodate the curve of the pit.

- You’ll only need to split four firebricks (use the technique shown in step 11), which you’ll place across from one another around the pit to create draw holes for oxygen for your fire.

- After you split your firebricks, dry-set them in place on top of the footing.

- Adjust the spacing between bricks so you won’t have to cut the last brick to fit (cutting firebrick isn’t easy).

- Mark the position of every brick on the footing.

Mortar the Firebrick

- Firebrick is mortared with refractory cement, which, unlike regular masonry mortar, can withstand high heat.

- Refractory cement comes premixed in a bucket and has the consistency of peanut butter.

- Pro tip: A margin trowel makes it easier to scoop cement out of the bucket and butter the bricks. And a tuck pointer is useful for cleaning up the joints.

- Work with four bricks at a time.

- Pro tip: The secret is to trowel the cement on thin, like you’re spreading peanut butter on toast, and use the tightest joints you can.

- Butter a thin layer of cement on the footer and position your first brick.

- Butter the second brick and butt it against the first.

- Continue around the circle checking level side-to-side and back-to-front as you go.

Create Air Holes

- Leave gaps in the firebrick in four opposite points around the ring and then fill them with half bricks. These gaps are “draw holes” that feed air to the fire.

- Prop up the half bricks until the mortar sets.

- Check for level across the DIY fire pit and the vertical level of the bricks as you go.

Complete the Outside Walls with Face Brick

- We used SW (“severe weathering”) face brick (also called “common” or “building” brick) to line the outside circle fire pit walls. If your climate doesn’t include freeze/thaw cycles, you can use MW (“moderate weathering”) building brick. Home centers and brickyards carry a large variety of brick.

- You’ll need 80 face bricks for a 3-ft.-diameter pit. Face brick with holes (“cored”) is easy to split with a brick hammer. It’s easier to form the curve of the pit walls with half bricks. You’ll lay three courses of face brick and mortar them together with Type N mortar mix (sold in 80-lb. bag at home centers, and you’ll need about five bags).

- Because face brick is smaller than firebrick, you’ll need to make up the size difference as you lay your three courses of face brick. The difference between the height of your firebrick and the total height of three stacked face bricks will determine the width of your mortar beds between courses.

- Dry-set the face brick, marking where each course of face brick has to hit the firebrick to make the third course of face brick level with the firebrick.

Split 80 Bricks in Half

- Cup the brick in your hand, keeping your fingers below the top edge of the brick.

- Pro tip: Our mason doesn’t use gloves, but we suggest you do!

- Give the brick a solid tap (a very solid tap for firebrick) on the outside edge near the center hole.

- Avoid hitting your hand. Repeat 79 times.

Set the Face Brick

- To keep your mortar joints between courses a reasonable width, lay a 2 to 3-in. thick bed of mortar right on top of the footing.

- Let it set up slightly (give it at least 15 minutes) and smooth out the top.

Work in Sections

- Working on one-third of this easy fire pit at a time, lay 3/8 in. of fresh mortar on each course of face brick into place, leaving a 1/4-in. gap between the firebrick and the face brick.

- Check the level of each course and tap down the bricks as necessary.

- Stagger the joints between courses for strength.

Strike the Joints

- After you finish each section of face brick, use a jointer to smooth (“strike” or “tool”) the joints before the mortar dries too much.

- The mortar is ready to strike if you press your finger into it and the indentation remains.

- Striking gives the wall a uniform, polished look.

- Remember to leave the draft holes open as you mortar each section of face brick and smooth out the finished joints.

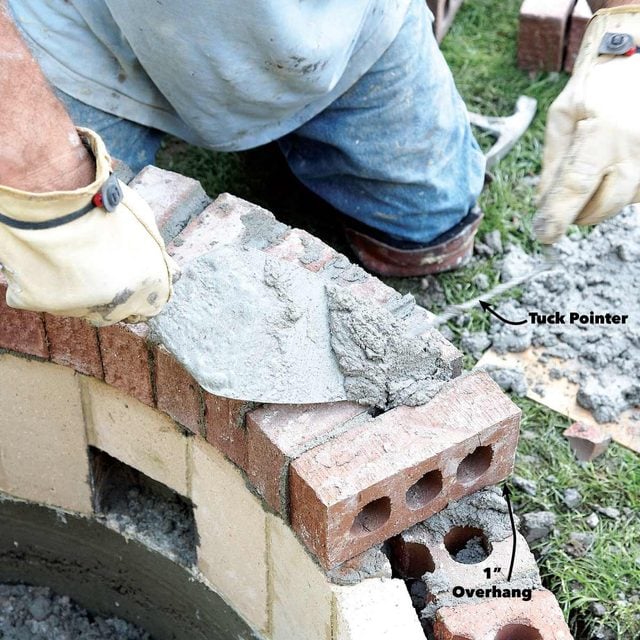

Finish Off the Top Lip

- Mortar the brick caps.

- Finish the pit with a matching “row-lock” cap using regular face brick set on edge.

- You’ll need about 40 face bricks for this cap, which will:

- Help protect the wall joints from rain

- Keep sparks contained

- Give you a nice ledge to warm your feet on.

- Work with 10 to 12 bricks at a time.

- Lay a 3/8-in. bed of mortar and lay the bricks on edge, then butter each brick on the outside edge as you go and press it into place.

- Pro tip: We used brick, but you could use natural stone for a different look.

Fill Gaps

- Add a small amount of mortar to the joints to fill any gaps.

- Check the level frequently and tap gently with a brick hammer to adjust the spacing.

- Leave a 1-in. overhang on the outside to allow for rain to drip off.

- Once all the bricks have been mortared in place, strike the joints for a smooth, finished look with a concave jointer.

Finished DIY Fire Pit

- Give the cement and mortar a week to cure completely before lighting a fire in your pit.

- Pour a few inches of gravel on the pit’s floor for drainage and you’re ready for your first wienie roast.