How to Build a Garden Pond Deck

Updated: Jun. 13, 2023Plans for a rectangular reflecting pond with ground-level boardwalk.

- Time

- Complexity

- Cost

- Multiple Days

- Beginner

- $501-1000

Build this deck and pond

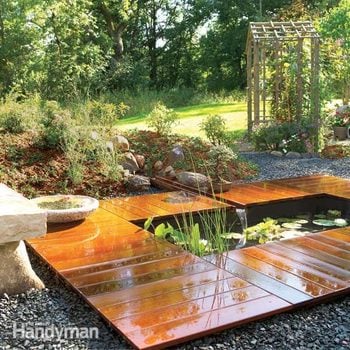

Are you in need of a little serenity? A reflecting pond is just the place to rest your gaze after a trying day. The one we chose for this issue is unique, not only in appearance, but also in building technique.

Most ponds are free-form, informal shapes that have either soft or hard plastic liners dug into the ground. But for ours, we used simple wood walls to frame it and form the base for the surrounding deck. A single-piece rubber liner keeps the water in. And the garden berm that surrounds one end is practical as well as a nice landscaping feature. We simply mounded the soil dug from the pond hole so we wouldn’t have to haul it away.

This pond isn’t exactly a weekend project. In fact, even if you’re in great shape, you should expect to spend the better part of a long day just digging the hole and laying in the gravel footings. The good news is that the construction is simple and doesn’t require a bunch of expensive tools. The only power tools you’ll need are a circular saw, a screw gun and possibly a plate joiner (or biscuit joiner; Photo 16) for the boardwalk. The techniques we show are simple to master.

How Much Will It Cost?

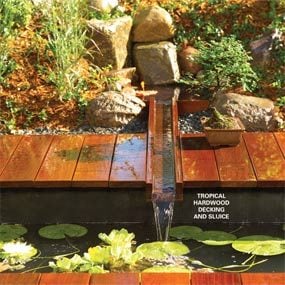

You can spend as much as $3,000 if you build the “Full Monty” version we show, featuring a state-of-the-art filtration system, expensive exotic decking and concealed fasteners. In fact, we spent about $1,200 just on the hardwood decking (called Ipe; more on this later), including a 14-ft. long boardwalk that connects the pond to a nearby patio. We spent $1,450 more on the pond filtration kit. Keep in mind that garden ponds are notoriously difficult to keep clean; we wanted an almost no-maintenance system.

But you can do this project for less than $1,000 by using standard decking materials and skipping the filtration system altogether.

Planning the project

The first step in planning your pond is to determine its size, depth and location. Size: Our 4 x 8-ft. pond is surrounded by a 30-in.wide boardwalk so it encompasses an area about 8 x 12 ft.

Your pond can be virtually any size or shape you’d like. The basic how-to steps on footings, wall framing and boardwalk will work for almost any layout you choose. Just make sure you select a pond liner and liner pad that’ll fit. Determine the liner and pad size by adding the height of both walls to the bottom dimensions plus 2 ft. for both the length and the width. Be aware that fitting the liner and building the boardwalk will be more complicated if you choose an exotic pond shape like a “T.”

Pond depth: A 3-ft. depth allows deeper water plants like water lilies to thrive and protects pond fish from predators.

Whatever depth you choose, make sure the tops of the pond walls stand above the surrounding grade at least 5 in. and at most 10 in. so the boardwalk footing design will work with your pond. It’s smart to dig the hole, then pour in the gravel base and measure to grade to determine the final stud height.

Location: For this pond design, you should have an area in your yard that has less than 8 in. of grade change over the footprint of the pond and boardwalk. To help pick a location, lay out a garden hose that outlines the boardwalk. You’ll be surprised at just how large an area it encompasses, especially when you include room for the berm.

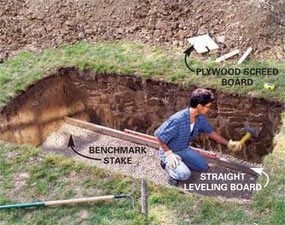

Overhanging trees will retard water plant growth and drop lots of leaves in the water, so it’s best to avoid them if possible. Once you’re satisfied with the location, use our technique of laying out the pond hole and berm position. Then use stakes and strings and “upside down” marking paint to prepare for excavation (Photo 1).

Winterizing: If you live in a freezing climate, you’ll have to drain the pond halfway and remove the pump. Fish and some plants won’t make it through the winter. You may have to bring them inside.

CAUTION!

Ponds are drowning hazards for children. This design is especially hazardous because the overhanging boardwalk makes climbing out difficult. If children have access to your yard, build a fence with a lockable gate around the pond.

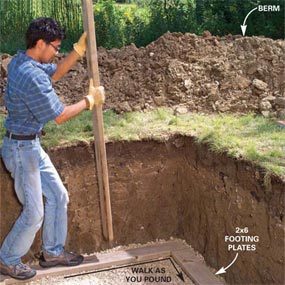

Digging the hole

After marking the pond and berm with spray paint, throw the excavated dirt into the berm perimeter. You’ll be able to sculpture the berm’s final shape and size as you excavate. We suggest digging the hole only 1 ft. larger than the pond walls to minimize digging and the amount of gravel fill needed against the pond walls (Photo 10). But in loose soils, the hole walls may begin caving in and you may have to dig a larger hole.

Don’t let the hole sit for days on end before you set up the pond walls because the sides will eventually collapse, especially if it rains.

Choose the highest grade point to determine digging depth and dig down 32 in. from that point. That way the 36-in. high pond lip will still be several inches above grade after you add the gravel footing. Use any type of clean gravel or sand for the 4-in. deep pond footing and base.

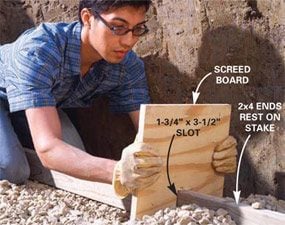

The finer the gravel, the easier it is to level. Just roughly level the gravel with a steel rake, then follow the simple method we show using stakes and a screed board to level the gravel footings directly under the walls (Photos 2 and 3). If your soil is sand, only dig a 38-in. deep hole, skip the gravel and use the sand for the footings, liner base and backfill.

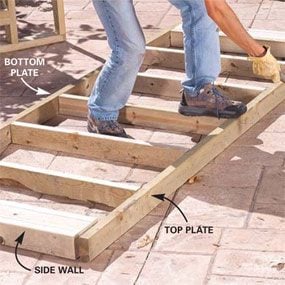

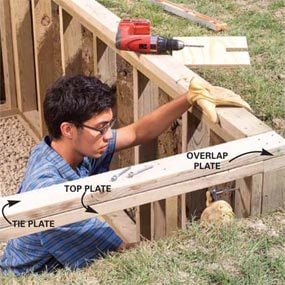

Treated wood walls

We recommend ground contact (.40 retention) treated wood for the wall, footings and deck framing. If foundation-grade lumber (.60 retention) is available at the lumberyard, choose it for all the below-grade materials and the pond structure will last virtually forever. Use double hot-dipped galvanized nails for fastening the framing but screw the plywood to the inside with deck screws. Nails could work their way out and puncture the liner.

Note that each layer of pond wall plates overlaps the one below it (Figure A, in Additional Information, below). That’s to spread the load over a larger area, help tie everything together and even out slight inconsistencies in heights.

Installing the liner and the liner pad

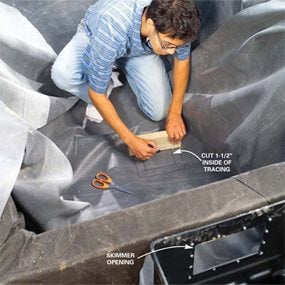

The liner pad protects the rubber liner from being punctured by sharp stones and rough framing surfaces. Before you install the liner pad, carefully inspect the walls and take care of protruding fastener heads, splinters or sharp stones that could work their way through and puncture the waterproof pond liner.

It’s easiest to install the liner pad by cutting a separate piece slightly larger than the bottom and then cutting separate pieces for the sides. They hang over the pond lip and drape over the walls (stapled to the outside), overlapping the bottom liner. You can cut up the liner pad as much as you need to as long as you overlap the pieces. Keep pleats and folds to a minimum and the pond liner will fit better.

We spread out the pond liner on the grass and roughly cut it to size with a utility knife before dragging it over the pond and pushing it into position. It’s easy to catch it on sharp objects and puncture it, so be careful. Slip out of your shoes and work in your socks when standing on top of the liner and fitting it against the walls. The key to a good-looking job is neat corner pleats, so spend some time on careful folds. After filling the pond with water, tack the liner around the outside with roofing nails and cut off the excess.

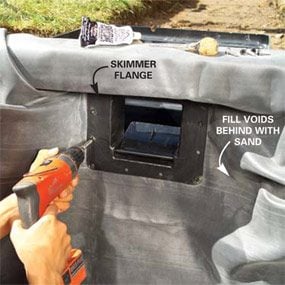

Customizing the skimmer and biofilter

The skimmer and biofilter (see “Buy a Biofilter, or Drain and Scrub.”) need customizing to work in your particular pond. First of all, you’ll have to measure the width of the skimmer inlet, including the skimmer flange (Photo 9). Custom-size the wall opening to fit your skimmer opening.

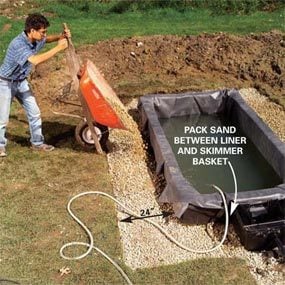

We recommend making it about 4 in. wider than the skimmer flange to accommodate folding the liner through the wall and screwing it to the skimmer basket. The opening height isn’t too important, since the basket sits outside the wall. After the liner is clamped to the skimmer, fill the space between the wall opening and the liner with sand to support the liner against the pressure of the water (Figure A, in Additional Information, below).

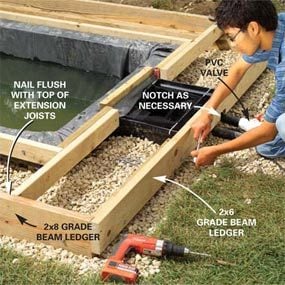

The pumps that come with the kits are generally powerful enough to drive a sizable waterfall over the lip on the biofilter. To throttle down the water flow to the trickle needed for the sluice, buy a separate PVC valve to fit in the hose leading from the skimmer to the biofilter (Photo 11). But simply replacing the kit pump with a smaller one may make more sense because it’ll cost less to run.

Buy a pump that lifts water 6 ft. (it’ll say on the back of the pump box) and a smaller hose that fits the pump outlet and is long enough to reach from the skimmer to the biofilter. Drill holes above the water lines of both the skimmer and the biofilter baskets for threading the hose through and connecting the new pump. The water line in the biofilter must run all the way to the bottom of the biofilter so the water can flow up through the filtration system. Keep the larger pump for draining the pond when necessary.

Our biofilter came with a separate lip that functions as a spillway or built-in waterfall. We discarded the lip and cut a replacement spillway out of decking and then cut a slot to receive the sluice (Figure B, in Additional Information, below, and Photo 20). The replacement spillway is then caulked and screwed into the biofilter spillway opening and the sluice is sealed in the slot with silicone caulk.

Under the boardwalk

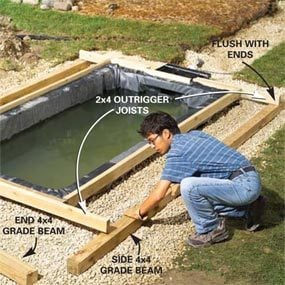

Dig the shallow 24-in. wide boardwalk footings before the pond is filled with water and backfilled with gravel. That way you can pour gravel against the pond walls and fill the footings at the same time (Photo 10). But if you have crumbly soil, it’s best to dig the footings after the pond is backfilled to keep soil from caving in against the walls.

The footing depth should be about 10 in. below the pond rim everywhere. If the terrain is slightly sloped, the 4-in. deep gravel footing will slope as well. Don’t worry about the slight slope; just try to rake out obvious humps for a consistent surface.

After you place and roughly grade the 4-in. deep gravel, it’s just a matter of nestling the 4×4 “grade beams” into the gravel the correct distance away from the wall (Photo 14). They don’t have to be perfectly level, just fully supported by the gravel. You’ll be able to make the fine adjustments when you attach the 2×6 grade beam ledgers to the 4×4 grade beams.

Tip:

Dig the skimmer and biofilter basket holes deeper than needed and fine-tune the bottom heights by adding gravel. It’s easier to level than soil.

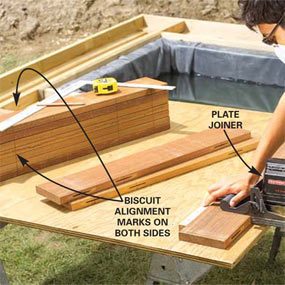

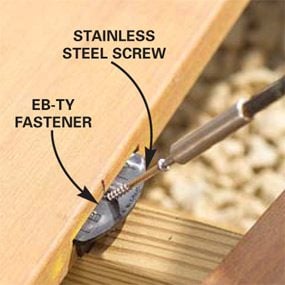

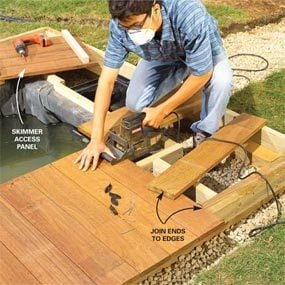

Ipe decking and invisible fasteners

Our boardwalk is made of a tropical hardwood named Ipe. At twice the price of 5/4 x 6 standard decking cedar or about the same price as clear cedar, it’s not for everyone. Because the wood we chose is so clear and beautiful, we decided to use an invisible fastening system called EB-TY so unsightly screw- or nailheads wouldn’t mar the appearance. If you don’t want to use this system, stainless steel trim head screws would be another good option. The EB-TY system is a variation of standard plate joinery with plastic biscuits substituted for wooden ones.

You’ll need a plate joiner to cut the slots into the decking edges for the biscuits. Then you slip the plastic biscuits into the slots and screw them into the joists with the stainless steel screws included with the kit. Biscuits are also added to the deck boards overhanging the pond but are not secured to any joists. They further support the overhang and keep the decking aligned. Deck boards that aren’t biscuited to neighboring boards need to be face screwed.

Buy a Biofilter, or Drain and Scrub

You have a decision to make about how much time you want to spend caring for your pond. We purchased a pond kit that included the liner pad, liner, pump, hose, skimmer and biofilter for about $1,400. You can also purchase all the parts separately over the Internet or at larger garden centers. The biofilter contains bacteria that cleanse the water of the nutrients that feed pond-choking algae. The system is reasonably easy to install and keeps your pond clean and balanced.

The kit makes the pond virtually maintenance free. Here’s how the system works: Water flows from the pond into the skimmer where mesh catches larger debris. At the bottom of the skimmer, a pump sends the water to the biofilter, where it rises through the filter. Now clean, the water flows out the basket to run down the sluice and back into the pond.

For a cheap alternative to the biofilter system, drain the pond a few times during the summer with a sump pump and scrub the algae from the bottom and sides. Refill the pond with fresh water.

Fish waste will accelerate algae growth, so you’ll reduce the work by banning fish from your pond. You’ll still have to buy the liner pad, the liner and a small pump if you want to put in a sluice. The pump can rest on the bottom of the pond with a water line leading under the boardwalk to the top of the sluice. Take care to choose a pump that can lift water at least 6 ft.

Additional Information

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Biscuit joiner

- Caulk gun

- Chalk line

- Circular saw

- Cordless drill

- Drill bit set

- Hammer

- Hearing protection

- Level

- Miter saw

- Safety glasses

- Screw gun

- Spade

- Speed square

- Tool belt

- Utility knife

- Wheelbarrow

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 1/4 x 3" lag screws with washers (40)

- 16d galvanized box nails

- 2 x 2 stakes

- 2-in. deck screws

- 2x4 10' (1)

- 2x4 10' (6)

- 2x4 8' (15)

- 2x4 8' (2)

- 2x6 10' (1 )

- 2x6 8' (2)

- 3-in. deck screws

- 3/4" gravel (2.5 yds.)

- 3/4" plywood 4x8 (3)

- Access panel framing (treated) 2x2 8' (1)

- Biofilter

- Decking 5/4 x 6 8' (23)

- EB-TY deck fasteners (200)

- End grade beam ledgers (treated) 2x6 10' (2)

- End grade beams (treated) 4x4 8' (2)

- End pond ledgers (treated) 2x4 10' (1)

- Garden hose

- Landscaping paint

- No. 20 biscuit slots

- Outrigger joists (treated) 2x4 10' (2)

- Pond liner

- Sand (5 yds.)

- Side grade beam ledgers (treated) 2x6 12' (2)

- Side grade beams (treated) 4x4 12' (2)

- Side pond ledgers (treated) 2x4 10' (2)