How to Build a Screened-in Porch

Updated: Jun. 07, 2022

Add an enclosed screen porch to your house using basic framing and deck building techniques.

Multiple Days

Advanced

$501-1000

Introduction

You can add a spacious, airy outdoor porch to your home. We'll show you everything you need to complete the project yourself, including how to frame the porch, attach it to your house and all of the finishing details. Sure, it'll take a lot of time and work, but once it's done, you can beat the bugs and spend more time outdoors during the summer.Tools Required

- Chalk line

- Circular saw

- Cordless drill

- Drill bit set

- Hammer

- Hearing protection

- Level

- Mason's line

- Miter saw

- Reciprocating saw

- Safety glasses

- Scaffolding will make it easier to complete the roof work

- Socket/ratchet set

- Speed square

- Stapler

- Stepladder

- Table saw

- Tape measure

- Tin snips

- Tool belt

- Utility knife

Roll up your sleeves!

A screened in porch is a big improvement, but building a porch is also a big project, one that might consume most of your spare time this summer. So, we’re keeping this how to build a porch design simple.

Simple 2×4 wall construction.

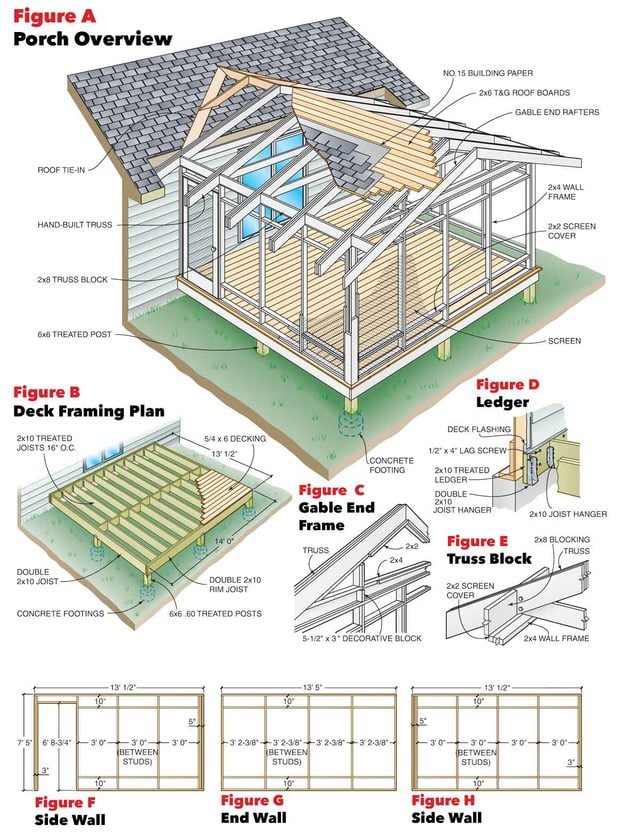

You can build it with standard dimensional lumber, and it doesn’t require heavy beams or complex joints. The simple 2×4 walls are light and airy looking. Two horizontal bands of 2x4s set 10 in. from the top and bottom of the wall, add a design element and stiffen the 2×4 framing enough to support the hand-built trusses.

With this how to build a porch design, there’s no need to precisely align the overhangs. And the exposed rafters and open soffit look great on many house styles.

The total cost of this how to build a porch was $6,500, but you could save hundreds of dollars without sacrificing quality by substituting treated decking for the cedar or using tongue-and-groove pine rather than cedar on the ceiling.

Straight forward construction.

Even though how to build a porch project is a large project, most of the construction is straightforward. If you’ve built decks or sheds, you’ll be able to tackle this job with confidence. In this how to build a screened in porch article, we’ll show you the key steps for building this porch. Study the drawings and photos for more details.

The tools you’ll need:

The screened porch offers a nearly unobstructed view of the outdoors and you’ll need a full set of basic carpentry tools, a circular saw and a drill to build this porch. In addition, a reciprocating saw, a table saw and a power miter box will make the job go quicker and give you better results. To reach high places safely and easily, we recommend renting a rolling scaffold system for a month.

Project step-by-step (21)

Plan ahead to avoid construction headaches

You can add this screened in porch to almost any house, but attachment details may vary from what we show here.

- On most two-story houses, you won’t have to worry about tying into the roof, but you may have to situate the porch carefully to avoid covering a window.

- The house roof sloped 5 in. per foot (this is called a 5/12 slope) and extended 18 in. at the overhang. Your roof may vary from this, and the details of how the porch ties in will vary as well.

These illustrations above show the plans for the screened in porch, deck framing, gable framing, ledger, truss block, side walls and the end wall. To print these how to build a porch plan, see Additional Information at the end of this story.

Tips for joining the screened in porch and house roofs

If you’re not sure how to neatly join the screened in porch and house roofs:

- We recommend hiring an architect to help work out the details.

- Another option is to build a full-size mockup of a roof truss out of inexpensive and lightweight 1x4s. Figure out where the top of the wall plate would be if you built the porch according to our plans (Figures A – H). Then support the mocked-up truss at this height to see how the porch overhang meets the roof.

- If you don’t like the way the overhangs intersect, adjust the level of the deck slightly, alter the wall height or change the width of the overhang.

- Contact your local building inspections department to find out what’s required to obtain a building permit.

- Start this process at least a month before you plan to build. This will allow enough time to work through potential problems.

Build the deck square and level and assemble the perimeter joists

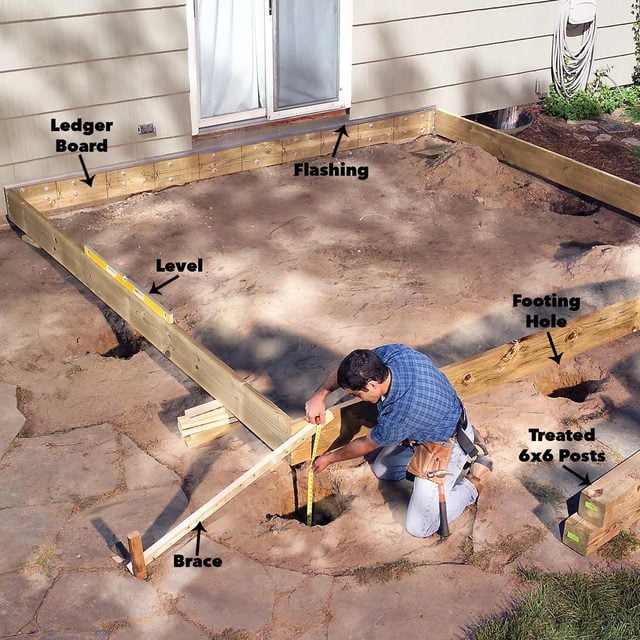

Install the ledger board.

Start by marking the ledger board location on the house wall. We located the top of the ledger board 90 in. below the bottom of the soffit. On our house, this left a 6-in. step down from the patio door to the deck surface. Remove the siding and attach the ledger with 1/2 x 4-in. galvanized lag screws (Figure D). Make sure it’s perfectly level. If the ledger attaches to concrete, predrill holes and insert lead shield lag screw anchors before installing the lags.

Outline deck frame and set beams.

After you mount the ledger, use stakes and string lines to outline the deck frame according to the dimensions in Figure B and mark the footing locations. A few days before you plan to dig the footings, call 411 to have underground utilities marked in the vicinity of the porch. Your local building department will specify how large and deep the footings should be for your climate and soil conditions. Pour a concrete pad in the bottom of each footing hole after they’ve been inspected. Let the concrete set overnight.

Assemble Frame.

Next, choose the six straightest 2x10s for the perimeter beams. Cut the 2x10s for the two side beams to length and nail the pairs together. Use 16d stainless steel or double-dipped galvanized nails for all of the joist framings and to attach the joist hangers to the ledger board. Rest one end of each side beam in the double joist hangers and prop them up until level with a stack of wood.

Install the joists and joist hangers

Nail through the joist hangers into the beams at the house to hold them in place. Then connect the opposite ends of the two beams at the front with a 2×10 cut to the same length as the ledger. Adjust the resulting frame until the diagonal measurements are equal.

Then brace the frame against stakes pounded into the ground to hold it square while you install the treated posts, joists and decking. Sight along the outside rim joist occasionally and adjust the length of the joists as needed to keep the front rim joist straight.

Cut away the overhang and siding to make way for the porch

You’ll have to decide whether to cut a slot where the porch walls meet the siding. If your siding is stucco, brick or stone, you may want to butt the walls to the siding.

Make a mark 1-5/8 in. out from the deck on both sides. Then make another mark 5-1/8 in. inside the first mark. Draw plumb lines up from these marks and cut a 5-1/8-in. slot through the siding but not the sheathing. Set the saw blade just deep enough to cut through the siding only. Remove the siding. Waterproof the slot with No. 15 building paper.

Cut away the roof

If your house has an overhang, you’ll have to cut it back flush to allow the innermost truss to fit against the wall. Start by removing the soffit and fascia boards above and several feet to each side of the deck. It’s easier to remove extra soffit and fascia boards and patch them back after the porch is done than to calculate cutoff points now. After the soffit boards are removed, use a level to plumb up from the house wall to the underside of the roof boards, in line with the outside edges of the porch.

Mark the two points. Then drive a long screw or nail up through the roof boards at the two marks. Snap a chalk line between the nails and remove the shingles below and about 6 in. above the line. Chalk a new line and remove nails along the line. Then saw along the line and pry off the roof boards. Be sure to wear safety glasses and hearing protection when you’re sawing. Finally, cut off the rafter tails flush to the house wall.

Construct a jig to assemble the roof trusses

Prime Before Painting.

Prime and paint the truss parts, wall frame and screen stops before assembly. Prime the wood with a special stain-blocking primer such as Zinsser’s oil-based Cover-Stain. Then brush on a coat of acrylic exterior house paint. Make sure to prime every cut end as you work; otherwise, these areas will absorb moisture and cause staining. We prefinished the roof boards with an oil finish (Cabot Clear Solution Natural).

How to construct the roof truss jig:

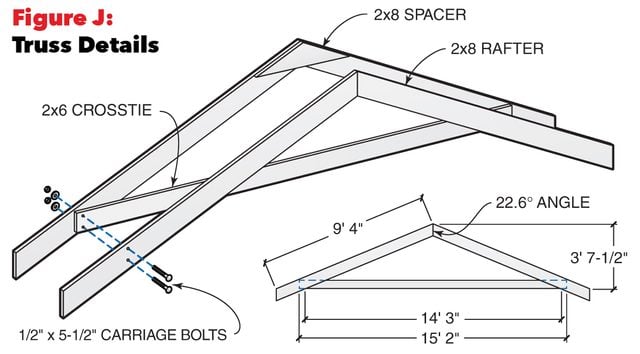

It’s easiest to assemble the roof trusses first, using the deck platform as a work surface. Screw two sheets of plywood to the decking and use the dimensions in Figure J to chalk lines indicating the top of the rafters and the bottom of the 2×6 crosstie. Cut triangular blocks and screw them to the plywood to hold the rafters in alignment as you assemble the trusses.

Build the trusses

How to use the jig:

Cut a rafter using the dimensions in Figure J and use it as a pattern to mark the remaining rafters. Place a pair of rafters in the jig and screw the tops together. Next screw the 2×6 crosstie and 2×8 spacer to the pair of rafters. Keep the crosstie screws clear of the bolt hole locations. Complete each truss by screwing another pair of rafters on top.

Assemble the rafters and trusses.

Check the ends and tops of the rafters as you assemble the trusses to make sure they’re perfectly aligned. The trusses must be identical so that your roof boards and soffit trim will line up. Finally, elevate the truss on blocks of wood while you drill a pair of 1/2-in. holes into each end of the crosstie for the carriage bolts (Figure J). Run the 1/2 x 5-1/2-in. carriage bolts through the rafters and crosstie ends and tighten the nuts.

Frame the walls accurately for smooth assembly

Since the wall framing for this screened in porch is the finished surface, it’s worth taking a little extra time to make the framing material look good. We chose the nicest cedar 2x6s we could find and ripped them into 3-1/2-in. and 1-1/2-in. boards. We did this to create sharp, clean edges (we also ripped off all the factory rounded edges).

Cut the studs and crosspieces to length and screw the walls together (Figures F – H). We used a power miter saw for clean, square cuts, but a circular saw will work too. Use a crosspiece as a spacer when you’re attaching the studs to the top and bottom plates. Then cut a 10-in. spacer block to position the crosspieces for assembly.

Plumb and brace the walls

Stand the walls and screw the wall corners together. The key to standing the walls is to check and double-check along the way to make sure they’re straight along their top and bottom plates, perfectly plumb and square, and securely braced. Start by positioning the walls with their outside edge flush to the deck and screwing them down. Next, screw the corners together, making sure the top plates of adjacent walls are even with each other. Use a long level to plumb the walls while you attach diagonal braces to hold them in position. Leave the braces in place until after the roofing is complete.

Attach the Trusses

You’ll need helpers for this step.

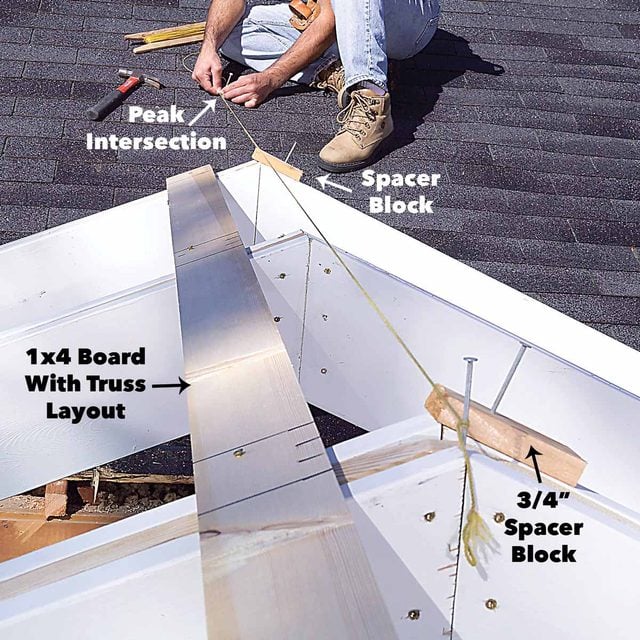

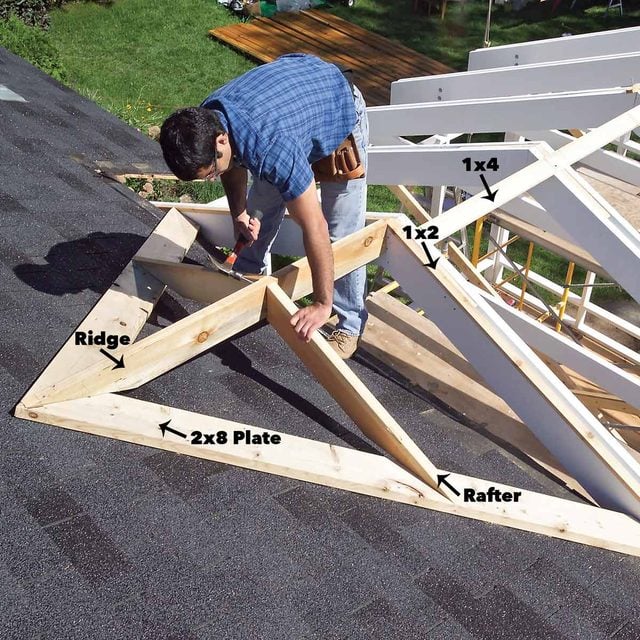

Round up a couple of strong helpers to assist in setting the trusses. Start by marking the position of the trusses on the top plate and onto a 16-ft. 1×4 (you’ll use the 1×4 to brace and position the tops of the trusses as you stand them up). The first truss simply butts to the house wall. The outermost truss aligns with the edge of the top plate, and the three interior trusses are centered on the studs below. Set the first truss against the house and carefully center it so that 1-1/2 in. of the bottom 2×6 overhangs the top wall plates on each side.

Installing the first truss.

Screw the truss to the top plates. Then use a straightedge and level to stand the truss perfectly plumb and brace it to the roof. Make sure this brace is securely screwed to the roof and the truss because the remaining trusses will be supported by this truss until the roof tie-in framing is complete.

Install the remaining trusses.

Lift the remaining trusses onto the top of the walls and rest them on the first truss. Slowly and carefully slide the outermost truss to the outside end of the porch. Align the marks on the 1×4 with the truss at the house and the outermost truss and screw it to the trusses.

Center the outermost truss on the walls and toe-screw it to the top plate of the walls. Stretch a string line between nails at the peak of the two trusses. Align the remaining trusses with the string line and the marks on the 1×4 and top plates and screw them in.

Line up the tie-in framing with the porch for a seamless blend

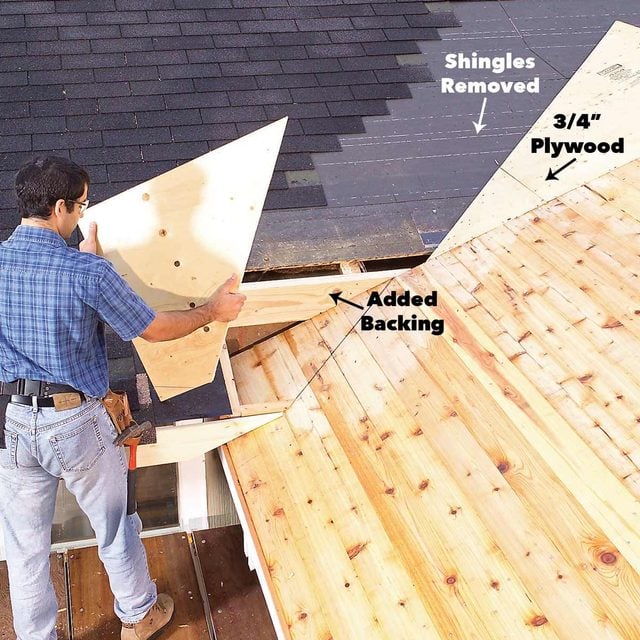

One of the trickiest parts of the porch construction is joining the two roofs. The key is to extend lines from the new porch and mark where they intersect the existing roof. Do this by using a taut string line or a long, straight board. Remember to raise the tie-in framing on the existing house roof ¾ in. above the porch framing to compensate for the difference in thickness of the 3/4-in. plywood and 1-1/2-in. roof boards, so use 3/4-in.-thick spacer blocks to raise the line to the correct tie-in framing height.

Install the ridge and rafters

Cut the 2×8 roof plates. If you’re not good at calculating roof angles, start by estimating the angles and cutting the plates an extra 6 in. long. Then set them in place, remark the angles and recut them until they fit. Screw the roof plates through the roof boards into the rafters below. Next measure for the ridge, estimate the angle and cut it a little long. Trim the angle to fit and screw the ridge rafter to the first truss and roof plates. Complete the tie-in by installing a pair of rafters. The framing should be exactly 3/4 in. above the top of the trusses.

Install the roof boards

To bevel the first roof board, set your table saw or circular saw to 23 degrees and rip a bevel on the groove edge of the board. Align the board with the ends of the trusses and nail it with 16d galvanized nails. Install the remaining boards, making sure to snug the joints tight before nailing them. Let the boards hang out past the last truss to form the gable end overhang. Cut the last board on each side to fit at the peak.

When you’re done installing the roof boards, snap a chalk line at the gable (outer) end and saw them off to leave an 18-in. overhang. Finish the gable end overhang by installing a pair of rafters and the 1×3 trim. Hold the gable end rafters tight to the underside of the cutoff roof boards and screw through the roof boards to hold the rafters in place. Then cut 1×3 trim to cover the end grain of the roof boards. Extend the trim around the corners and return it along the roof edge to the house.

Pay attention to flashing and roofing details for a watertight job

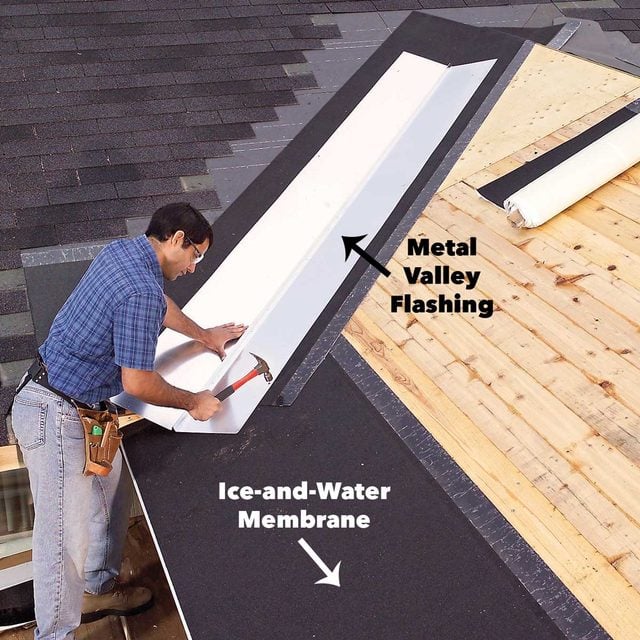

Building the tie-in framing on top of the existing shingles is a good way to keep the house waterproof as you construct the porch, but when it comes time to install the roofing you’ll have to cut the shingles along each of the valleys with a hook-blade utility knife. Then pry loose the cut shingles to make a wide path for the valley flashing.

Cover the tie-in framing with 3/4-in. plywood. Add blocking as needed and fill in the triangular areas between the existing roof and the new roof.

Install flashing in the roof valley

We won’t go into how to roof a house here. In general, cover the eaves and valley with strips of a waterproof membrane (an ice-and-water barrier) and install the sheet metal valley. Place roofing nails about 12 in. apart along the edge of the metal valley. Cut a short piece of valley metal to complete the top on each side, overlapping it about 6 in. onto the long piece.

Staple No. 15 building paper to the remainder of the porch roof, starting at the bottom and working up. Overlap each row 3 in. onto the one below. Install shingles to match the house. Follow the manufacturer’s instructions for starting, overlaps and nail placement. Use 1-in.-long galvanized roofing nails to avoid nailing through the tongue-and-groove ceiling.

Fill in the porch gable ends

Cover the triangular opening in the truss above the house wall by building a 2×2 frame and nailing 1×6 tongue-and-groove boards to the back. Then slide the frame into the opening and screw it into place. Fill the triangular space above the outside wall with a 2×4 frame (Figure C).

Then staple screening to it and cover the screens with stops, just as you do with the walls below. Practice on scraps to make accurate patterns for the steep angles. Then transfer the angles to the actual framing members. You may have to cut these angles with a handsaw; they’re too steep for a miter saw unless you build a special jig.

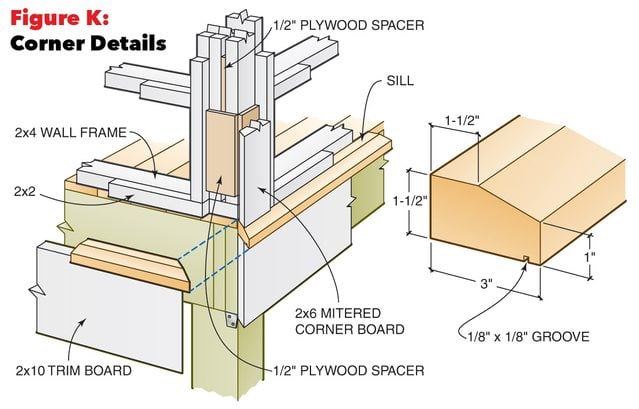

Attach trim and sill to the outer walls

Nail a 2×10 trim board over the outside joist, 1-1/2 in. below the top surface of the deck. Cut a 2×4 sill piece to width and bevel the top on a table saw. Miter the ends and nail the sill to the top of the 2×10 trim board.

Trim corner details

This illustration shows how the corners are assembled and the trim is installed.

Staple the screen to the walls

The charcoal aluminum screening we used is strong and long-lasting, but you have to handle it carefully to avoid creases and dents. Carefully unroll the screen on a large work surface and cut lengths about 3 in. longer than you need. Reroll each piece and carry it to its location.

Start by tacking the two corners, making sure the screen is square to the opening. Then stretch the screen slightly and staple the sides, top and bottom. Place 1/4-in. staples every 3 in.

Attach 2x2s over the framing

After you stretch and staple each section, cut off the excess screen with a sharp utility knife. Then cover the edges with 2×2 trim pieces. We screwed these on to allow for easy removal for future screen repairs, and the trim covers the staples along all of the edges. Frame and screen the outer gable end following Figure C.

Screen door details:

If you use a wood door like ours, start by trimming it just enough to fit in the opening. Then set it in place and mark the door for final fitting. Use a sharp plane or belt sander to trim the door. You may have to repeat this process a few times to get a good fit.

Nail 1/2 x 2-in. wood stops to the framing at the door opening. Then hang the door using galvanized or brass screen door hinges. Mount a latch and door closer to complete the job.

Additional Information: