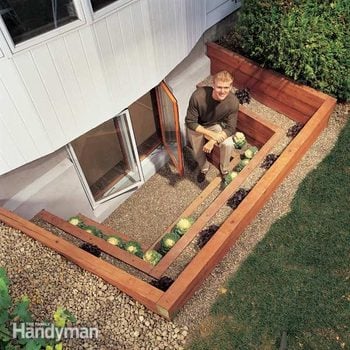

How to Install a Terraced Window Well in Your Basement

Updated: May 01, 2023How to build a series of low walls around your basement windows to let in more light.

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $501-1000

Design for safety

The primary rules for designing a window well are the code requirements for an egress window. The bottom of an egress window well must be at least 3 x 3 ft., the well can’t interfere with opening the window, and you have to provide a permanent ladder if the walls are more than 44 in. high. Terracing our well eliminates the ladder requirement.

Otherwise, you’re only limited by safety and drainage issues. Any window well is inherently dangerous because of the potential for falls. Covered window wells are safest, but you can’t let the cover hinder the window operation and it must be easily removable (without tools) to provide easy egress and emergency escape.

Terracing minimizes the danger of a fall. We recommend that you construct the widest terraces and lowest steps that your site will allow. You could also put a railing around the egress window well, a feature we recommend if you have a walk nearby. The egress window well we’re building opens onto a spacious yard, away from walkways.

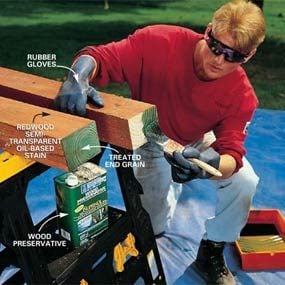

Still, we took the extra precaution of adding a curb about 8 in. above grade plus flower beds and low bushes to keep folks from stepping into it. We constructed our terraced well with 4×6 treated wood timbers because they’re long lasting, easy to cut and level, and economical. To dress up the timbers, we stained all sides before installation with an oil-based semi-transparent redwood stain.

Decorative concrete wall block is another good choice for terracing. This block will last forever, but it’s about twice as expensive as wood and harder to cut and assemble. Another option is to buy a manufactured well. These range from the corrugated steel culvert style (available in most home centers) to manufactured terraced wells.

Good drainage is critical

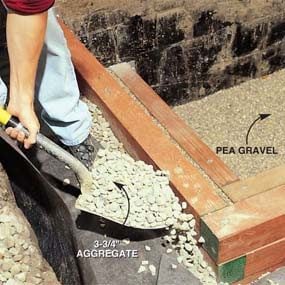

If your basement hasn’t suffered any moisture or flooding problems, digging a window well or expanding an existing well is unlikely to create water problems, as long as you follow the instructions in the photos. The two sizes of gravel we show provide a path for water to easily flow down into the soil without filling up the well. The landscape fabric acts as a filter to prevent soil from clogging the gravel drain field.

Soil with a high clay content, however, poses another problem. This soil tends to trap water instead of letting it drain away. For yards with clay soil or poor drainage, or for damp basements, consult a professional before undertaking the project. (Check the Yellow Pages under “Waterproofing Contractors.”)

One option to ensure good drainage is to tie the well’s drain field into the existing drainage system around the footing of your basement (Fig. A). If you don’t know if you have foundation drains, you’ll have to call the builder or the city department of inspections, or dig down to the footing at the bottom of the wall and look for a gravel bed with a plastic or other type of pipe. If you find the pipe, simply fill the hole with 3/4-in. gravel to connect the two drain fields.

Some homes have drains on the interior, under the basement floor, and rely on a sump pump to get rid of water. Connecting to this type of system is more complicated and difficult. We suggest that you leave this work to a pro.

Be sure to show your plan to your local building inspector and obtain a permit. Ask about any special requirements and discuss drainage issues. The inspector should be familiar with local soil conditions.

Step 1: Dig and prep the hole

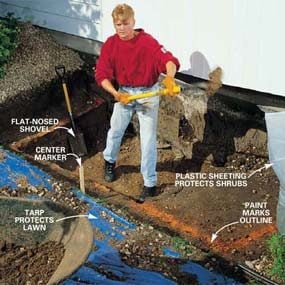

Photos 1-4 walk you through the steps for digging the well. Fig. A shows you the exact dimensions we used, but you can easily adjust them to fit your site. Your layout doesn’t have to be precise; a stake centered on the window will be accurate enough for digging (Photo 1).

To build the size well we show here, you’ll be removing a small mountain of dirt (more than 8 cu. yds.). Save your topsoil, but get rid of the rest of the dirt by renting a 20- or 30-yd. trash container. The oversized container gives you a large base so you don’t have to pile the dirt so high.

Make sure the trash container has a gate on the back that you can swing open for the wheelbarrow. Tell the waste company that you’ll be loading dirt in the container so it’s aware of the weight involved. If you have to put the container curbside, you’ll probably have to get a permit from the police department.

We built our entire well first, then added the window. But it’s easier to cut in your egress window after you’re done with the initial digging (Photo 2). Then finish the well.

TIP: Cover the excavation during rainy periods to keep water out and keep the walls from eroding.

Caution

Before doing any digging, always call your local utility companies (Natural gas, Water, Electric, Phone and Cable) to locate buried lines.

Step 2: Set the first row of timbers

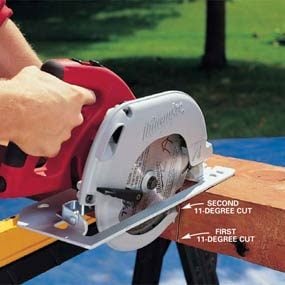

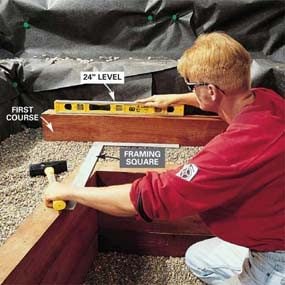

With the bottom level and the window accurately marked, lay out your wall pattern. Then measure the lengths and angles of the timbers and cut them (Photo 5). Often, the cuts expose untreated wood, so treat raw ends after cutting (Photo 6). Use a wood preservative containing copper (available at paint stores, hardware stores or home centers). Set the first row of timbers perfectly level (Photo 7).

Step 3: Set and fasten the remaining levels

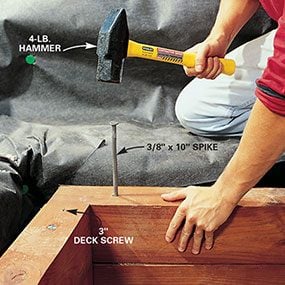

The process for the second row is exactly the same as for the first (Photos 8 – 11). Driving the spikes takes some effort, so be sure to predrill with a 12-in. bit (Photo 9). One good reason to backfill with gravel is to avoid the need for compacting (Photo 11). Backfilling with soil would require a lot of tamping to keep it from settling over the next year or two. Complete and backfill all the levels.

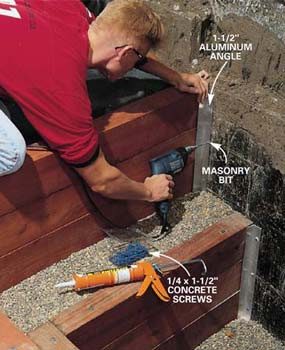

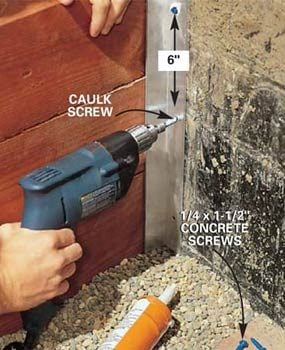

Step 4: Anchor the walls at the foundation

Photos 12 and 13 show you how to anchor the timbers against the foundation. Once you finish the well, scatter decorative stone over the surfaces to spruce up its appearance. If you decide to add plants, confine them to pots nestled into the gravel. That way soil won’t clog up the drainage. Or encourage vines to grow over the top and down the sides. But leave an uncluttered pathway open for emergency escape. Have you heard about faux basement windows?

Additional Information

Required Tools for this Egress Window Well Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Caulk gun

- Circular saw

- Corded drill

- Drill bit set

- Garden rake

- Hammer

- Level

- Paintbrush

- Safety glasses

- Sawhorses

- Spade

- Speed square

- Tape measure

- Utility knife

- Wheelbarrow

3/8-in. drill bit, 12-in. long

5/16-in. masonry bit

Required Materials for this Egress Window Well Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 1/4-in. x 1-1/2-in. concrete screws

- 3-in. deck screws

- 3/4-in. gravel

- 3/8-in. x 10-in. spikes

- 4 x 6 treated timbers

- 4-mil Plastic sheeting

- Exterior stain

- Fabric spikes

- Landscape fabric

- Pea gravel

- Plastic tarp

- Silicone caulk

- Spray paint

- Wood preservative