Making Deck Posts

Updated: Jan. 19, 2024Make square cuts, notches and grooves quickly and accurately

Deck Posts Overview: Benefits and tools

Honing your circular saw skills will pay big dividends when you’re building decks and fences. Good techniques will speed up your work, create stronger joints and show off your craft since all the cuts and joints are highly visible. In this story, we’ll show you how to get a perfectly square cut on the end of a 6×6 deck post, cut notches and shape deck posts with your circular saw.

You’ll need a circular saw with a sharp 7-1/4-in. blade to make the deep cuts we’ll be showing. A 24-tooth carbide blade (at hardware stores and home centers) is a good deck-building blade.

Square Your Saw Blade

You can’t make clean cuts unless the blade is square to the saw’s bed. Most saws have an adjustment screw near the angle gauge for this purpose. With the saw unplugged and the blade set to maximum depth, retract the blade guard and hold a square against the bed and blade to make sure they’re exactly 90 degrees to each other. Adjust the screw if necessary.

Next check to make sure the blade is parallel to the saw bed. With the saw unplugged and blade fully extended, hook a combination square or Speed square on the back of the bed and slide it tight to the blade. They should line up. Most saws don’t have adjusting screws for this. Make adjustments by carefully bending the bed sideways until the blade and bed are parallel.

Technique 1: Square-cut a 6×6 deck post

Here’s an easy method for making a smooth, clean cut on a 6×6 deck post when you cut it to length. By rotating the post a quarter turn after each cut, you can use the previous cut to guide the blade for the next cut. Since a 7-1/4-in. blade cuts a little less than halfway through, you’ll have to finish the cut with a handsaw. To prevent kickback, position both sawhorses on the keeper side of the line and allow the cutoff piece to fall.

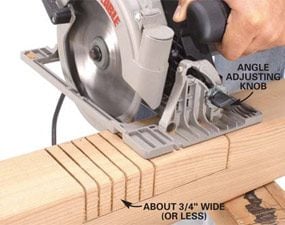

Technique 2: Notch a 6×6 post to support beams

Create a sturdy connection by notching a 6×6 deck post to accept a beam. You could make these notches using the technique shown in Technique 3 below, but the ripping method shown here is a little faster, especially for long notches. If you’re using treated posts, brush a wood preservative onto the freshly exposed wood.

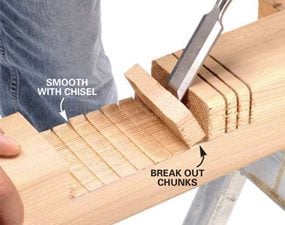

Technique 3: Notch the middle of a post

Rail posts often require notching to fit around a deck joist (Photos 2 and 3). Enclosed notches like these are easy to make with a series of saw kerfs. After the chunks are broken out, you’ll have a little cleanup to do with a sharp wood chisel.

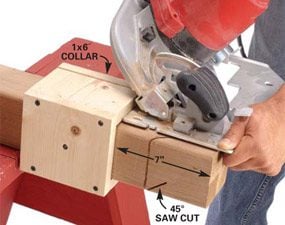

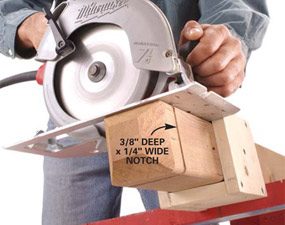

Technique 4: Cut a decorative 4×4 deck post top

Photos 1 – 3 show one way to cut a decorative post top using a simple wood collar as a guide for the saw. Make the collar by cutting two pieces of 1×6 about 1/32 in. longer than the post width and two more pieces 1-1/2 in. longer than this. Screw the pieces together to form a snug-fitting collar. Slide the collar over the 4×4 deck post and secure it with two screws on opposite sides to hold it in place. The holes left from the screws will swell shut and become nearly invisible with time. Practice various patterns on a scrap 4×4 deck post and keep track of all the collar locations by marking the post before you reposition the collar. When you have a design you like, simply transfer these marks to each post to duplicate the cuts.

In Photo 1, we show cutting the 45-degree angles on the post top before cutting the post to length. The extra post length supports the bed of the saw, making it easier to cut accurate angles.

You can cut any size groove with a circular saw if you’re patient enough to make multiple passes (Photo 3). But you’ll save time and get better results using the same collar to guide a router fitted with a straight-cutting router bit.

Required Tools for this Deck Posts Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Circular saw

- Drill/driver - cordless

- Handsaw

- Sawhorses

- Square

- Wood chisel