How to Pour Footings for a Solid, Frost-Proof Deck

Updated: Mar. 25, 2024

Prevent frost-heave damage by pouring the concrete right.

A full day

Beginner

Less than $20

Introduction

Dig and pour your deck footings so they extend below the frost line. That way, they won't move, or heave, as the ground freezes and thaws during seasonal changes. This article explains how to build solid footings that will stay put year-round.Tools Required

- Hoe

- Posthole digger

- Spade

- Tape measure

- Utility knife

- Wheelbarrow

Materials Required

- Concrete

- Form tube

How Deep is the Frost Line?

If your setting deck posts move up in the spring and then settle back down as the weather warms, then you have a bad case of “frost heave-osis.” Pouring footings doesn’t require much outside of a few basic concrete skills. But it does require you to ask a few important questions, and chief among them is this: how deep is the frost line? In the winter, the ground freezes from the top of the soil downward. The depth of frost penetration depends on the soil type, the severity of the winter, the amount of water in the soil and the depth of an insulating blanket of snow.

The frost depth varies by region. In frigid Minnesota, the frost depth is 42 in., whereas a warmer state like Missouri may have a frost depth of only 1 ft.

When you contact your local building department to get your building permit, ask what the frost depth requirement is and the required size and shape of the footings. Then dig the footing holes so that the bottoms of the footings are at or below the frost depth.

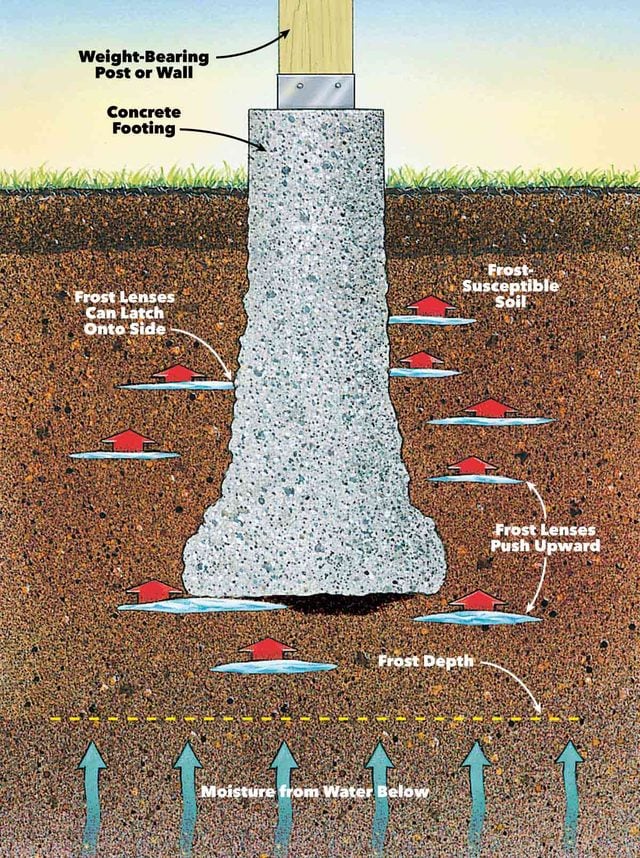

The mechanics of frost heave are complex, but here’s a quick primer. Water in the surrounding soil collects and freezes into thin layers of frost called “ice lenses.”

When water freezes, it expands about 9 percent—think of how ice cubes are domed above the original water level in the ice cube tray. Ice exerts a pressure of about 50,000 lbs. per square inch—enough force to lift even a large building. A puny little deck on inadequate footings doesn’t stand a chance.

The reason buildings and decks don’t always return to their original height is that surrounding dirt sometimes fills in under the footing while it’s lifted.

Heavy clay soils don’t drain well, so they tend to have more frost heave problems than sandy, well-drained ones. But even if footings are deep enough, ice lenses can latch onto the rough surfaces of wood and concrete and lift footings and posts from the side. That’s why concrete piers poured in waxed cardboard tubes and smooth wooden installing deck posts work well for below-grade support. Helical piers are becoming common in new construction of residential and commercial buildings, decks and outbuildings.

How to Get a Solid, Frost-proof Footing:

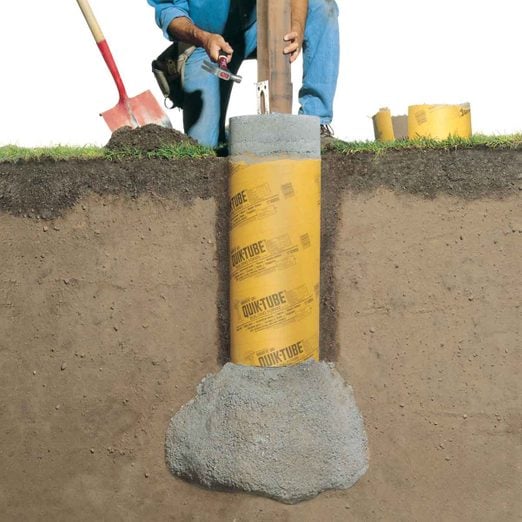

- When you pour concrete footings, hold the cardboard concrete form tube about 12 in. up from the bottom of the footing. Do this by nailing the sides of the tube to the center of a tic-tac-toe grid of 2x4s at the top of the hole. Then dump concrete through the tube into the bottom of the hole. After the wide part at the bottom of the hole has filled, the tube will fill too.

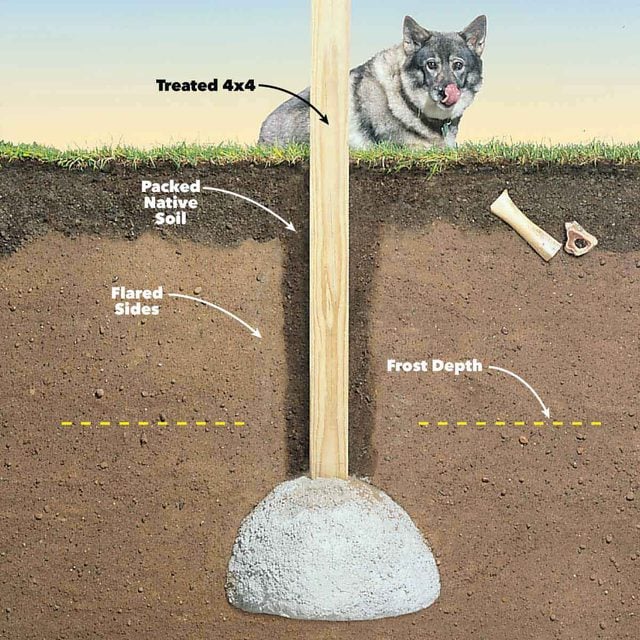

- Flare the sides on concrete footings so the footings will resist heave in harsh winters when frost penetrates especially deep. Greater width at the bottom will also distribute weight over a larger area.

- Mound soil around the posts after the backfill settles to direct runoff water away from the post.

Project step-by-step (3)

Ordering Premixed Concrete

If you’re pouring more than a few footings, order premixed concrete from a ready-mix company. You’d be shocked at how many bags of concrete mix you’d have to mix by hand to fill a form tube.

Figure concrete volume by multiplying the height of the post and column in feet by the radius of the tube in feet squared times 3.14. Divide the total by 27 to get the cubic yardage you need to order. Add extra for the wide footing bases.

A Footing Destined to Fail: Frost Line Depth Chart

If the footing does not extend below the frost line, the footing will heave as the ground freezes and thaws.

Post Set in Concrete

Even if you’re setting deck posts in the ground, instead of on top of footings, the concrete still needs to extend below the frost line.